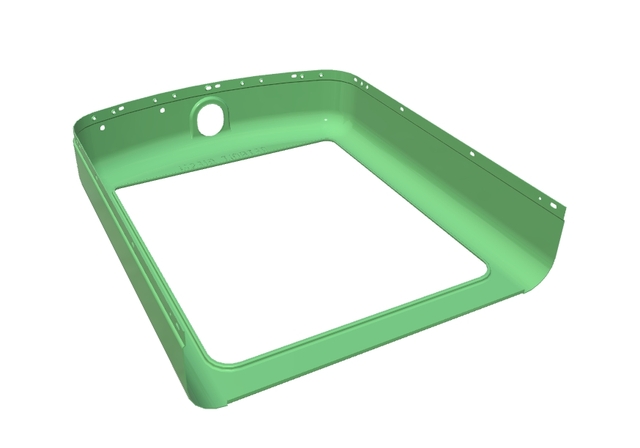

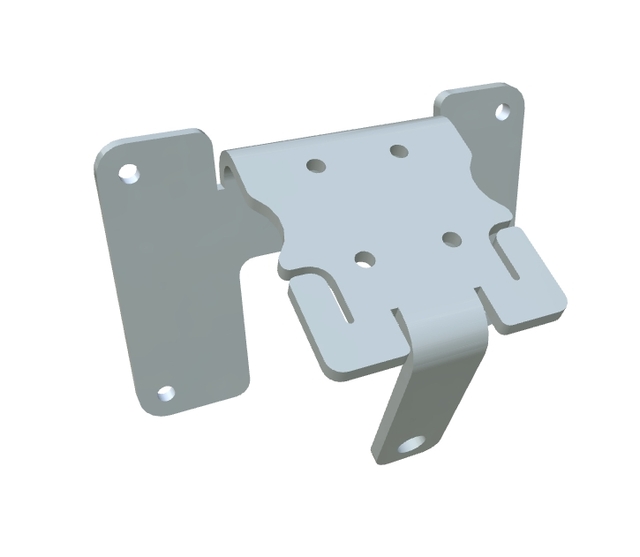

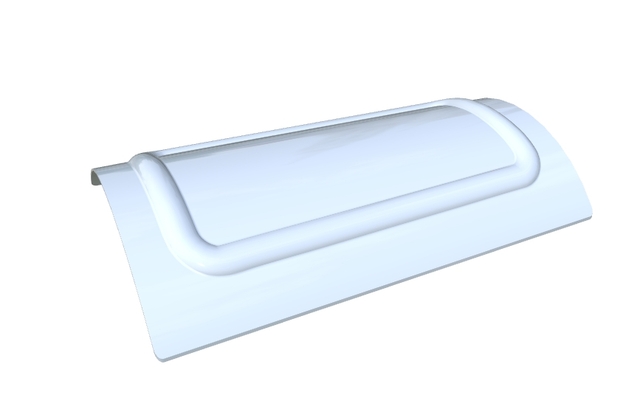

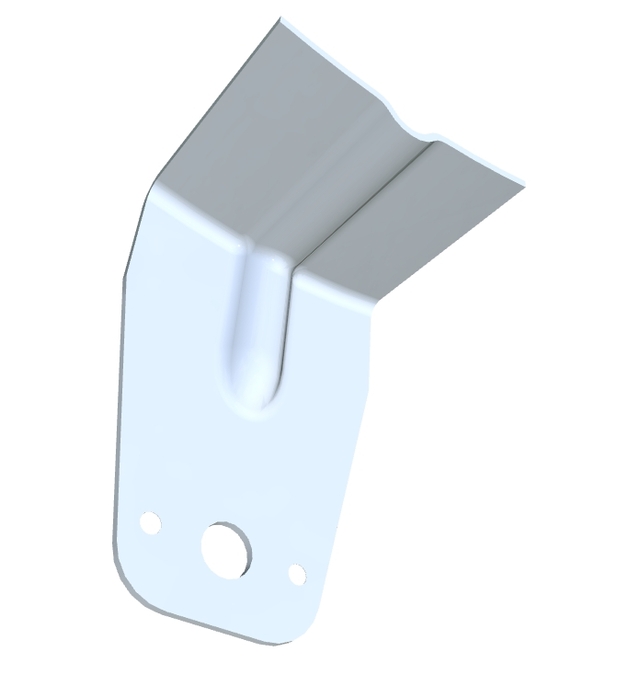

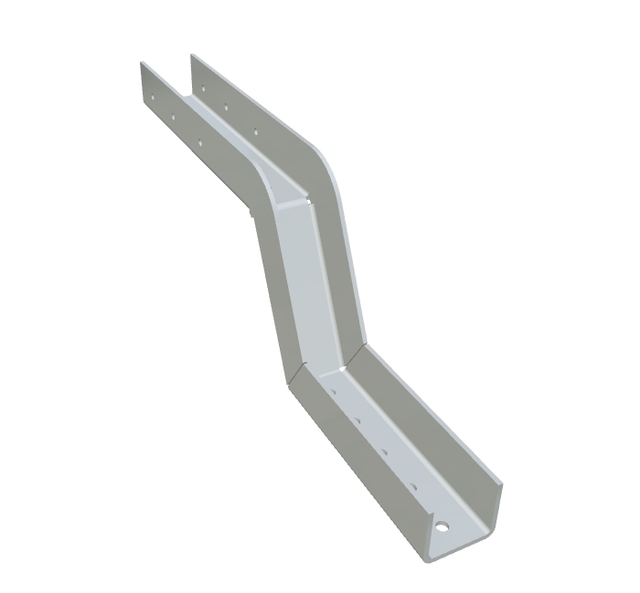

The domain of sheet metal fabrication has transformed industrial and structural applications, with numerous industries depending on its abilities to convert raw metal sheets into parts and components essential for various applications. Among these, the innovative Metal Mounting Bracket stands out as a premier instance of what high-quality sheet metal fabrication can achieve. Designed with precision and durability in mind, it embodies the perfect blend of function and sophistication.

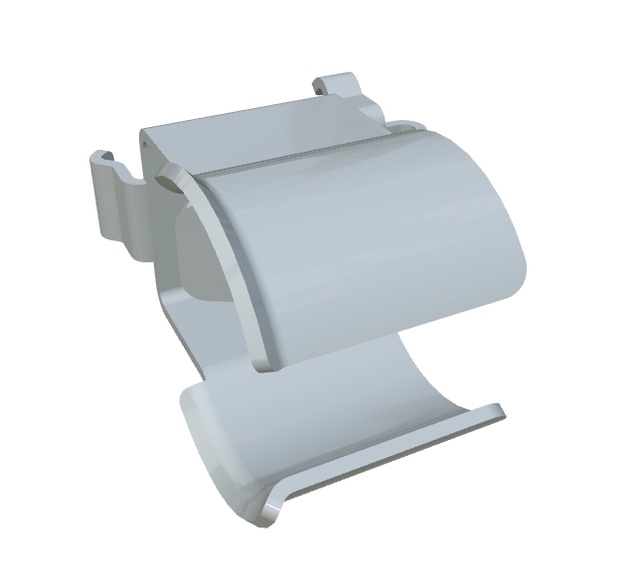

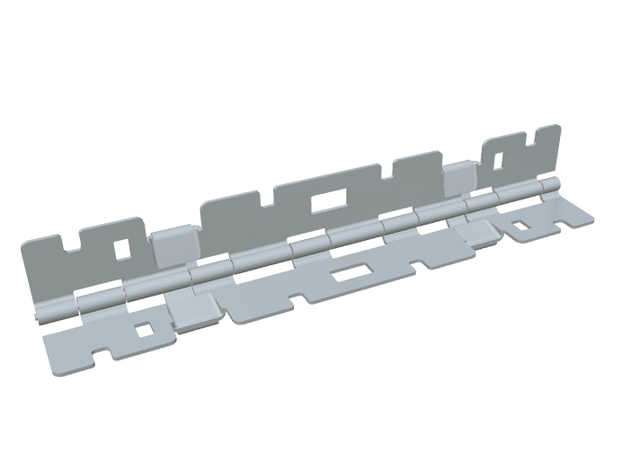

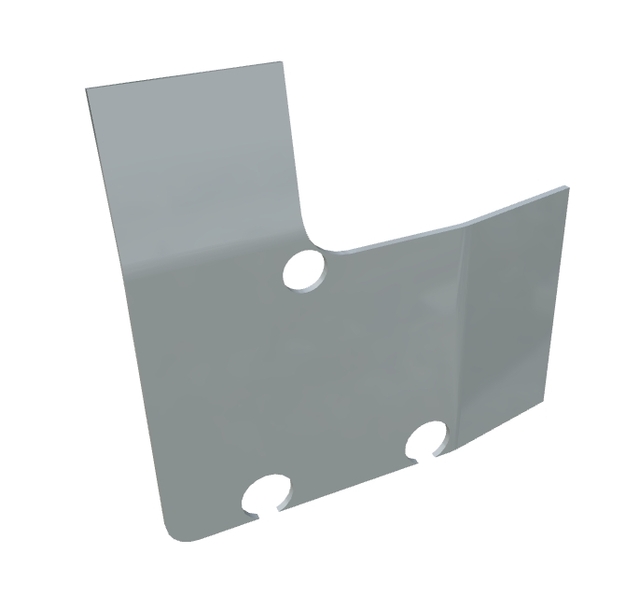

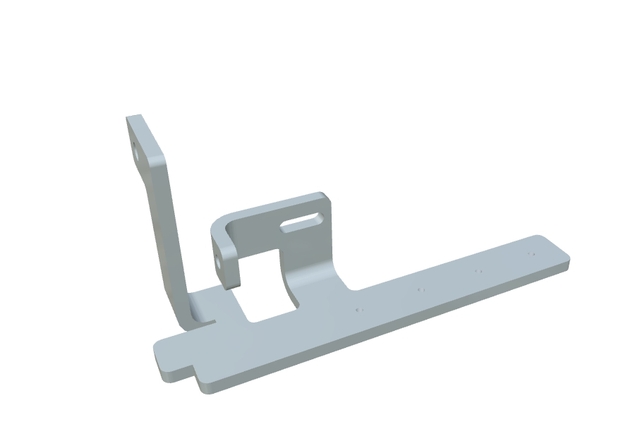

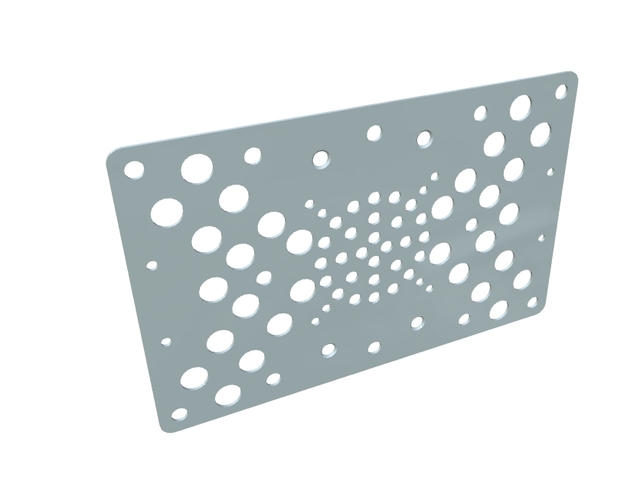

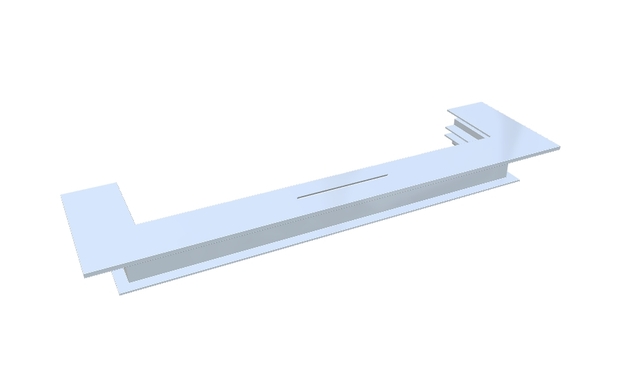

Sheet metal fabrication encompasses a broad spectrum of processes that manipulate metal sheets into desired shapes through cutting, bending, and assembling. The main_keyword, sheet metal fabrication, is integral to many sectors, making modern solutions like the Metal Mounting Bracket possible. The service offerings within this industry are wide-ranging, from metal fabrication services that cater to industrial giants, to custom sheet metal work which often serves more niche applications. One important aspect of this process is sheet metal bending, a critical step in shaping the metal to suit specific applications, and has found a significant role in the creation of the Metal Mounting Bracket's versatile design.

LS Hardware Tech Co., Ltd stands as a leader in this field, known for its innovative approach and high-quality outputs. Founded by Mr. Nick Zhang, with over 20 years of experience, the company has become a beacon of precision and reliability in the world of hardware and plastic parts manufacturing. Their commitment to quality is apparent in their ISO 9001:2015 certification and their extensive reach, serving more than 150 countries. The Metal Mounting Bracket is a testament to their expertise, featuring a minimalist yet robust design that merges practicality with aesthetics.

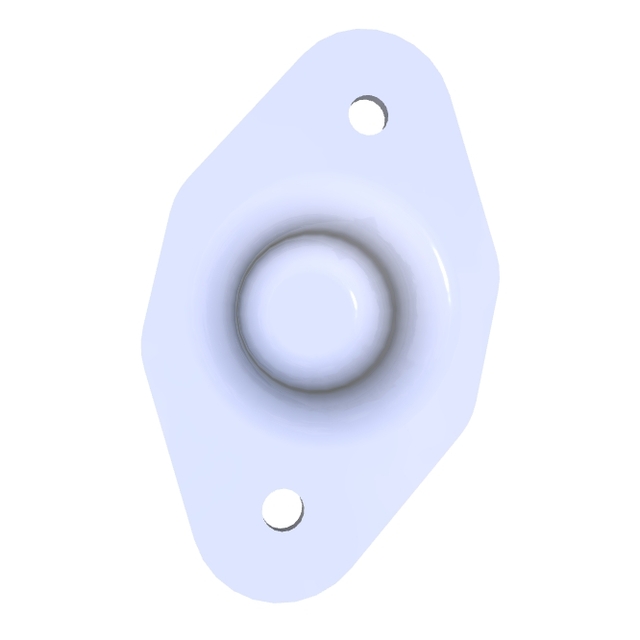

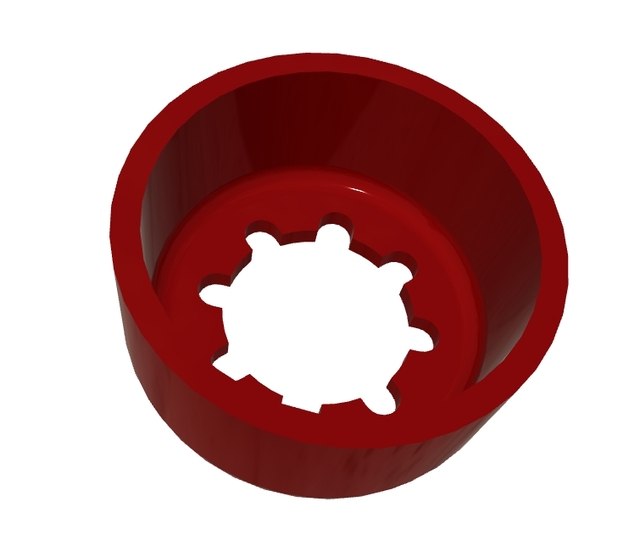

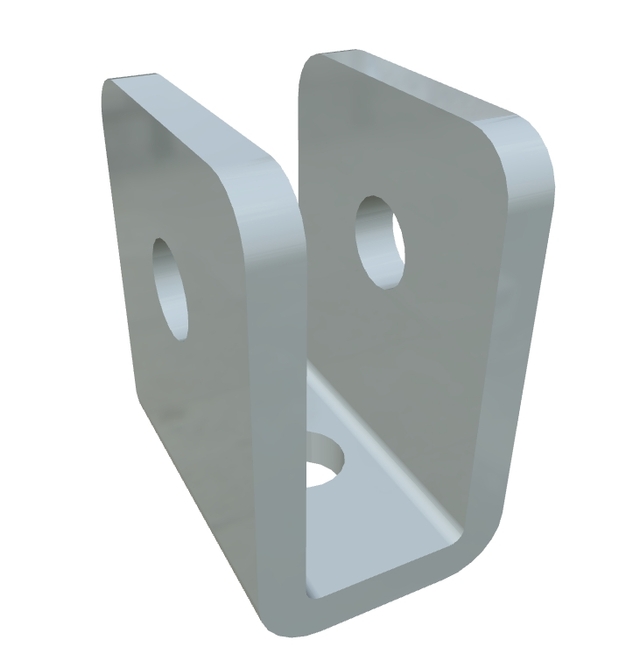

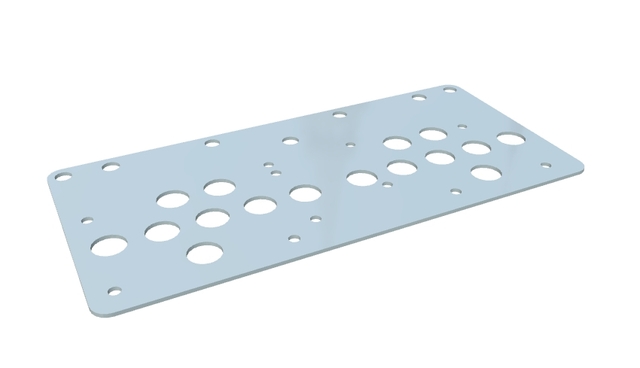

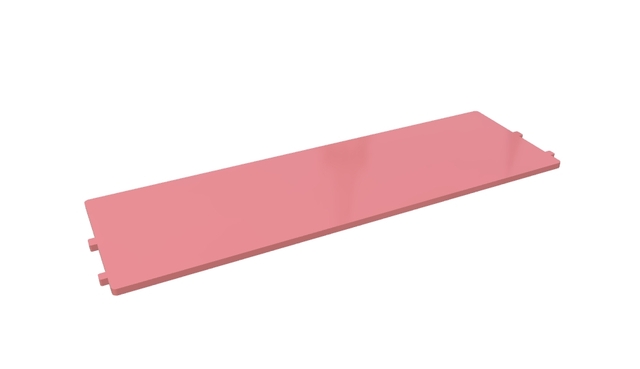

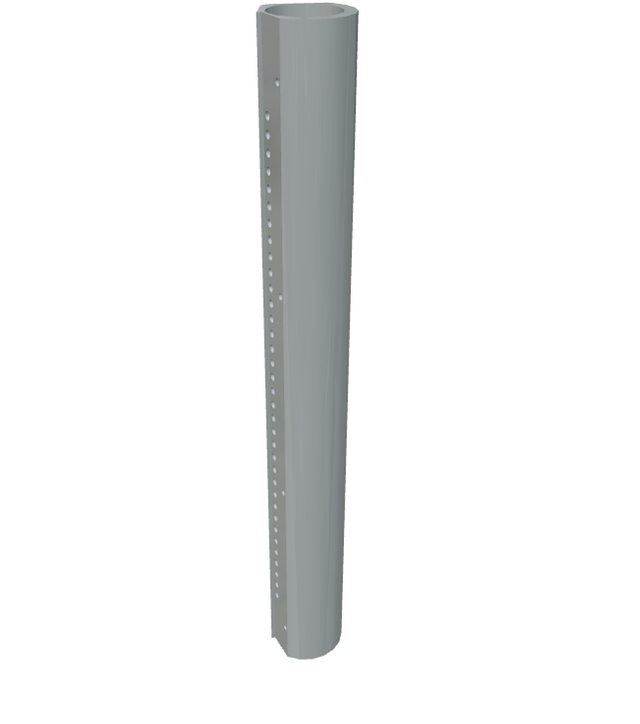

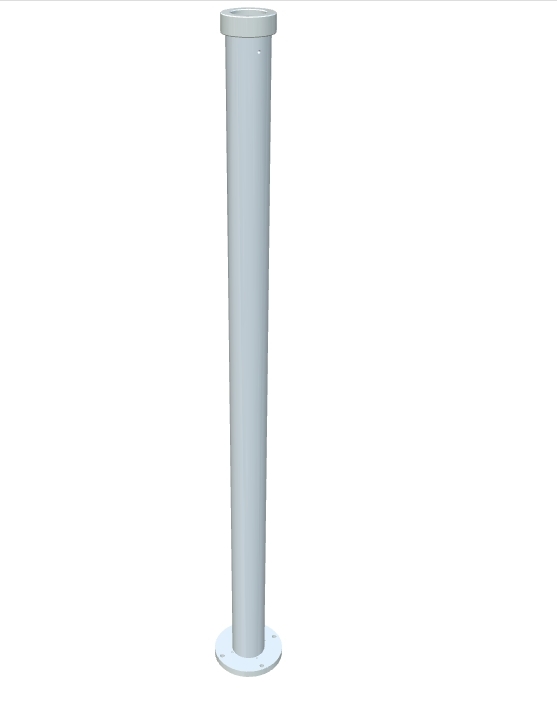

One of the standout features of this bracket is its pre-drilled holes, which ensure effortless installation and a firm hold in any setting. This attention to detail ensures that the Metal Mounting Bracket can be applied effectively in construction, cabinetry, or any project where a solid support system is imperative. Its design seamlessly blends into contemporary settings, offering both horizontal and vertical segments that provide endless possibilities for mounting and aligning components with precision.

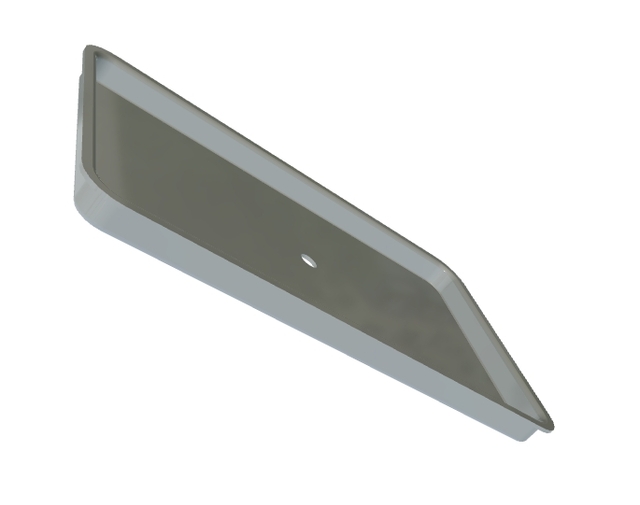

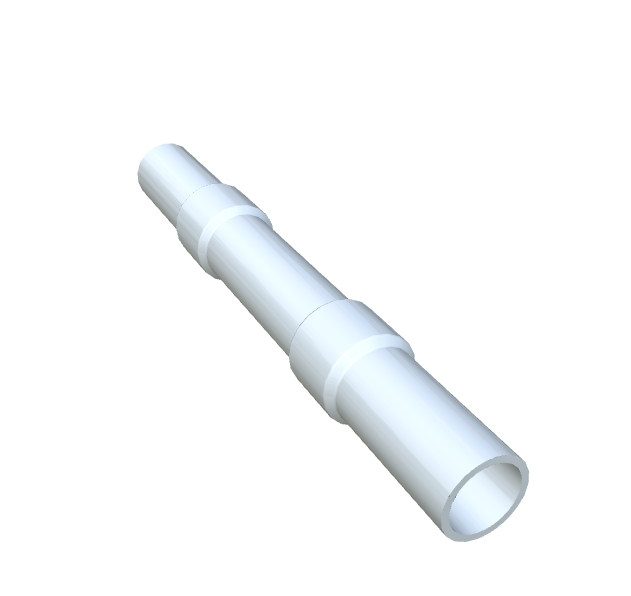

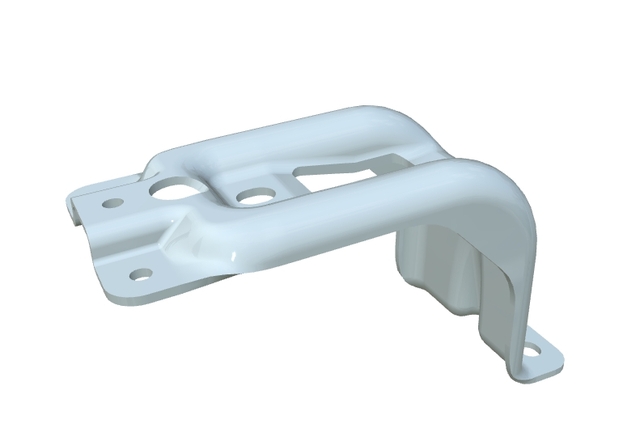

The sheet metal fabrication expertise of LS Hardware Tech Co., Ltd is evident in their application of CNC sheet metal cutting techniques, ensuring each piece is crafted to perfection. This precision offers a competitive edge in the market, particularly in aluminum sheet metal fabrication, which offers lightweight yet strong solutions, and steel sheet metal services, known for their durability.

Moreover, LS Hardware Tech Co., Ltd's use of metal stamping ensures that every Metal Mounting Bracket produced is both high-quality and consistent, meeting the rigorous demands of industries as varied as automotive and aerospace. These industries require the impeccable quality that only a precise and well-crafted product like the Metal Mounting Bracket can provide.

In summary, sheet metal fabrication is more than just a production technique; it is a transformative capability that allows for the creation of products that meet high standards of precision and performance. For LS Hardware Tech Co., Ltd, it's about enabling clients to bring their visions to life through innovative solutions. The Metal Mounting Bracket, with its robust yet sophisticated design, represents a pinnacle of what can be achieved in this field.

Whether you're engaged in industrial-scale projects or custom applications, the Metal Mounting Bracket offers a reliable and stylish support system that embodies the strengths of modern sheet metal fabrication. It's more than a product; it's a collaborative achievement of engineering excellence and design innovation.

Transformative Sheet Metal Fabrication with LS Hardware

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.