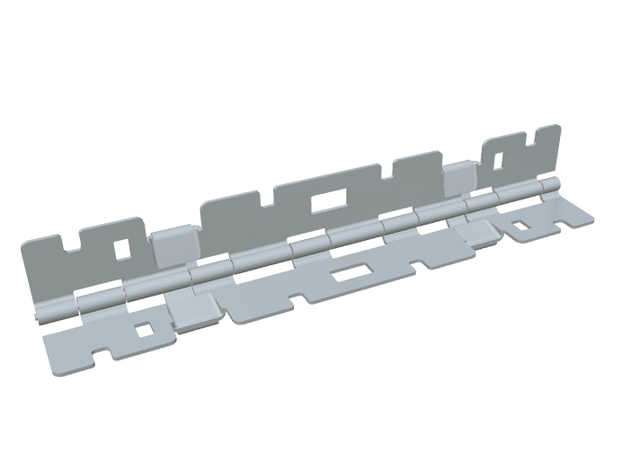

In the world of manufacturing and metalworking, progressive die stamping stands out as an essential process for producing high-quality components with remarkable efficiency. By utilizing progressive dies, manufacturers can achieve consistent, precision stamping services that cater to a wide range of industries. This process involves feeding a strip of metal through a series of dies, where each station performs a different operation until the desired shape is achieved. As a leader in the field, LS Hardware Tech Co., Ltd takes pride in offering cutting-edge automated stamping solutions that seamlessly integrate with modern production demands.

LS Hardware Tech Co., Ltd, helmed by the experienced Mr. Nick Zhang, specializes in the meticulous art of die manufacturing. With more than two decades of expertise, the company has become a cornerstone in hardware and plastic parts production, servicing over 5,000 satisfied clients worldwide. The company’s factory, laden with over 100 high-end machining centers, epitomizes high-volume stamping operations with a dedication to precision and quality. This commitment is underpinned by the company's ISO 9001:2015 certification, which further solidifies its status as a trusted partner, not only in China but across 150 countries and regions.

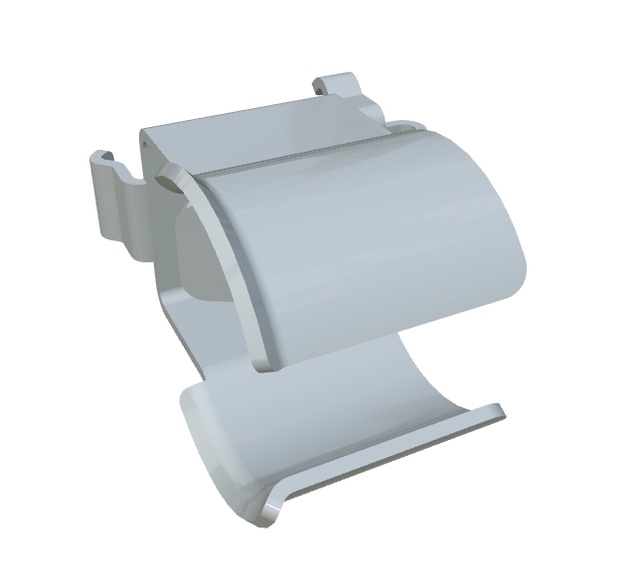

Our new product, a sleek and minimalist wall-mounted holder, epitomizes LS's dedication to precision and quality. Crafted with durable materials, the holder features smooth curves and a subtle matte finish, making it an ideal addition to any modern interior. Its versatile design ensures easy installation, securely gripping essentials and ensuring they are always within reach. Whether used in a bathroom, kitchen, or office, this chic holder offers the perfect blend of functionality and style, echoing the meticulous craftsmanship of our progressive die stamping techniques. The holder seamlessly harmonizes with contemporary decor, offering an innovative solution to organizing space efficiently.

The applications of progressive die stamping are vast and varied, with their impact visible across multiple industries like automotive, medical devices, consumer electronics, aerospace, and industrial equipment. The process delivers unmatched consistency and adaptability, making it ideal for mass production. By using progressive dies, LS Hardware Tech Co., Ltd ensures that products are manufactured with the highest standards, fulfilling the full spectrum of customer needs from prototypes to large-scale production runs.

Advancements in sheet metal fabrication and progressive die stamping have led to innovative manufacturing solutions, like our wall-mounted holder, that are both versatile and robust. In tandem with automated stamping solutions, these processes bring to life the innovative ideas of our clients with unparalleled efficiency. LS Hardware Tech Co., Ltd remains at the forefront of technological advancements, constantly refining processes to meet the evolving needs of customers and maintaining its position as a leader in die manufacturing.

In essence, LS Hardware Tech Co., Ltd represents the epitome of industrial prowess, with a firm foothold in producing high-precision parts through progressive die stamping. Our commitment to enhancing production efficiency and delivering top-quality products allows us to empower clients to manifest their creative visions. With a legacy rooted in excellence and innovation, LS Hardware Tech Co., Ltd is steadfast in its mission to deliver seamless solutions that address contemporary manufacturing challenges.

Progressive Die Stamping: Efficiency in Metal Stamping Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Progressive Die Stamping, Metal Stamping, Hydroforming, Deep Draw Stamping, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Progressive Die Stamping: Revolutionizing Metal Fabrication

Progressive Die Stamping: Innovative Metalwork Techniques

Revolutionizing Manufacturing with Progressive Die Stamping

Mastering Progressive Die Stamping: A Key to Precision

Progressive Die Stamping: Elevating Metal Component Production

Progressive Die Stamping: Precision & Innovation

Progressive Die Stamping: Efficiency in Metal Stamping Solutions

Progressive Die Stamping: Precision Meets Innovation