Progressive die stamping is a revolutionary technique in the manufacturing industry, offering unparalleled efficiency and precision in metalwork. This method, a cornerstone of precision metal stamping, ensures rapid production of high-quality and complex parts. LS Hardware Tech Co., Ltd, an industry leader, excels in utilizing this technique to provide innovative and reliable manufacturing solutions, satisfying the diverse demands of industries worldwide.

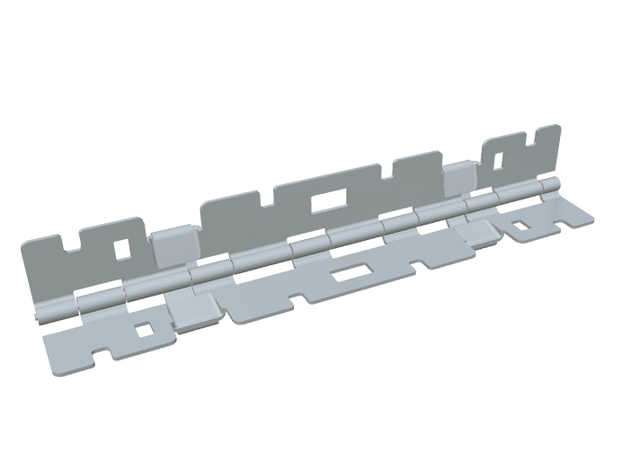

At the heart of the progressive die stamping process is its ability to perform a sequence of operations on a metal strip with a single tool. Each stroke of the stamping press machinery unveils a specific feature, harnessing multiple die stations to shape, cut, and bend the material into complex configurations. The precision of progressive die design is crucial here, ensuring each station performs flawlessly to achieve seamless assembly. The importance of this design cannot be understated, as it directly influences efficiency and the quality of the end product.

The automated stamping solutions offered by LS Hardware Tech are designed to maximize throughput while maintaining the highest standards of precision and quality. This advanced technology is critical for high volume stamping, reducing production times and driving down costs without compromising on the integrity of the components produced. Indeed, the progressive die stamping technique enables LS Hardware Tech to deliver unparalleled precision metal stamping services, which are crucial in industries such as automotive, consumer electronics, aerospace, and medical equipment.

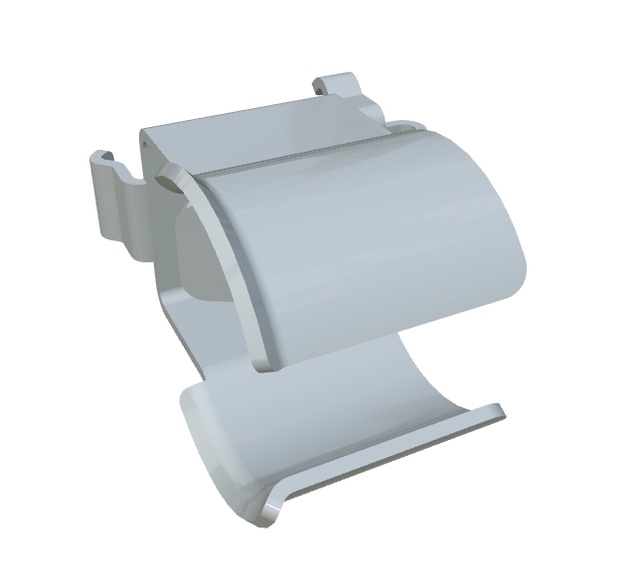

The company's dedication to precision is mirrored in its latest product offering: the Hole Saw Drill Attachment. This sleek, modern tool exemplifies high craftsmanship and innovative engineering, hallmarks of LS Hardware Tech's commitment to quality and durability. Engineered from high-quality materials, this cylindrical accessory boasts multiple openings designed for efficient, smooth cutting. Its cutting-edge design allows for seamless penetration into various materials, making it an indispensable tool for both professional and DIY projects. The robust structure ensures longevity, while its lightweight construction guarantees ease of use, blending functionality with contemporary aesthetics.

Founded by Mr. Nick Zhang, LS Hardware Tech Co., Ltd has grown into a globally recognized name, thanks to its robust infrastructure and dedication to excellence. With over 100 high-end machining centers and a sophisticated network of industrial facilities, LS Hardware Tech demonstrates a strong commitment to innovation and customer satisfaction. Backed by over 20 years of industry experience, the company continues to push the boundaries of what's possible in manufacturing, providing precision parts that meet the highest industry standards.

ISO 9001:2015 certified, LS Hardware Tech serves as a trusted partner to major factories in China and extends its services to more than 150 countries and regions worldwide. This global reach is supported by the company's mission to deliver innovative manufacturing solutions that empower clients to actualize their visions. LS Hardware Tech remains at the forefront of technology, perpetually enhancing its processes and capabilities to meet the evolving needs of its customers.

Progressive die stamping and other metal stamping techniques employed by LS Hardware Tech are essential in crafting a new generation of high-performance hardware. Through continuous improvement and a steadfast commitment to quality, LS Hardware Tech ensures its partners receive only the finest precision metal components, exemplary of their expertise and technological prowess. By integrating a seamless blend of innovative design, automation, and meticulous craftsmanship, LS Hardware Tech continues to elevate industry standards and redefine what is achievable in manufacturing.

Progressive Die Stamping: Innovative Metalwork Techniques

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Stamping, Progressive Die Stamping, Blanking, Hydroforming, Deep Draw Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Progressive Die Stamping: Revolutionizing Metal Fabrication

Progressive Die Stamping: Innovative Metalwork Techniques

Revolutionizing Manufacturing with Progressive Die Stamping

Mastering Progressive Die Stamping: A Key to Precision

Progressive Die Stamping: Elevating Metal Component Production

Progressive Die Stamping: Precision & Innovation

Progressive Die Stamping: Efficiency in Metal Stamping Solutions

Progressive Die Stamping: Precision Meets Innovation