Progressive die stamping is revolutionizing the manufacturing landscape with its unparalleled efficiency and precision. At the heart of the metal fabrication industry, progressive die stamping stands as a testament to technological advancement and innovation. This technique is a hallmark of LS Hardware Tech Co., Ltd, a leading enterprise in hardware and plastic parts manufacturing, deeply rooted in experience and expertise.

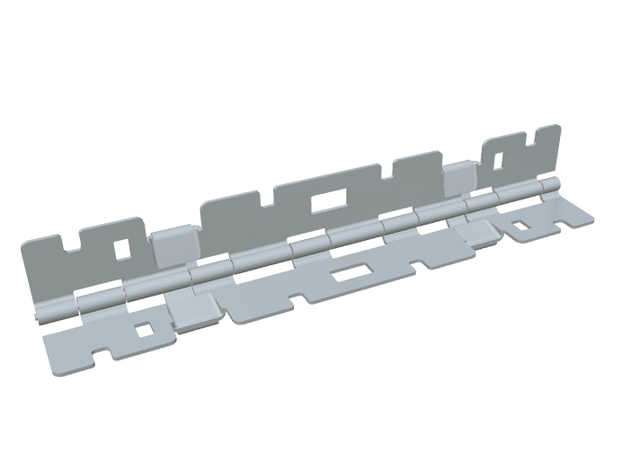

The die stamping process is critical for the creation of numerous metal components fundamental to many industries, from automotive to consumer electronics. Progressive die stamping, in particular, amplifies these capabilities by allowing for high-volume production with exceptional accuracy. This method involves a strip of metal fed through a series of dies, each one performing a distinct operation like punching, bending, or cutting. As a result, progressive die stamping yields highly complex parts in minimal time, meeting the fast-paced demands of modern industrial production lines.

LS Hardware Tech Co., Ltd, with its stellar reputation fostered by over 20 years of experience, is a prime example of expertise in this domain. The company's advanced facilities are equipped with more than 100 high-end machining centers, fulfilling the progressive stamping benefits that include cost efficiency and time savings. As a trusted partner to major factories in China, LS Hardware extends its services globally, revolutionizing manufacturing solutions and empowering clients to bring their innovative products to market quickly and efficiently.

The metal stamping techniques utilized by LS Hardware Tech Co., Ltd emphasize quality and precision. The company's ISO 9001:2015 certification underscores its commitment to quality assurance and process optimization. Progressive die applications are vast, catering to industries requiring high volumes of metal parts like aerospace and medical devices. This process not only reduces material waste but also leverages automation to further enhance production throughput.

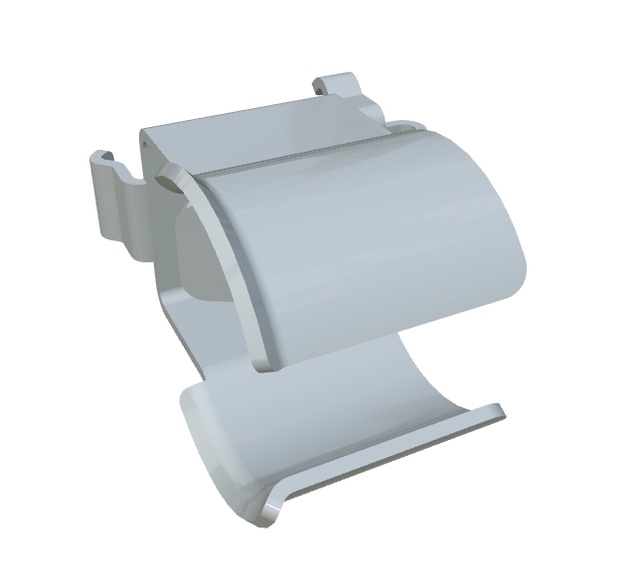

One can't discuss the cutting-edge nature of LS Hardware's solutions without highlighting the wireless control knob, a sophisticated device that demonstrates the result of their manufacturing expertise. This product encapsulates advanced stamping die design, leading to a sleek, modern look that seamlessly integrates functionality with contemporary aesthetics. The control knob is a perfect example of automated die stamping in action, featuring intricate components that are precisely crafted through LS Hardware's meticulous processes.

The demand for high-volume metal stamping is ever-increasing, with today's industries requiring flexible and efficient manufacturing methods. LS Hardware's progressive stamping stands at the forefront, promising not only scalability but also the robustness and durability of the final products. As industries evolve, so does LS, continuously pushing the boundaries of technology to stay ahead of the curve.

LS Hardware Tech Co., Ltd is more than a manufacturing partner; it is an innovator, constantly improving its processes to meet the diverse and changing needs of its clients. The robust construction of products like the wireless control knob, equipped with user-centric features like touch-sensitive technology and LED indicators, reflects LS Hardware's dedication to quality and modernization.

In conclusion, the progressive die stamping technique utilized by LS Hardware Tech Co., Ltd illustrates the fusion of precision, efficiency, and innovation. Through meticulous stamping die design and high-quality manufacturing facilities, LS Hardware shapes industries with its comprehensive solutions, fulfilling high-volume demands across the globe. The journey of this progressive method resonates with LS Hardware's mission to remain at the technological forefront and deliver superior manufacturing solutions, a pledge they continue to uphold as they enable their clients to realize their inventive visions.

Progressive Die Stamping: Revolutionizing Metal Fabrication

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Hydroforming, Blanking, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.