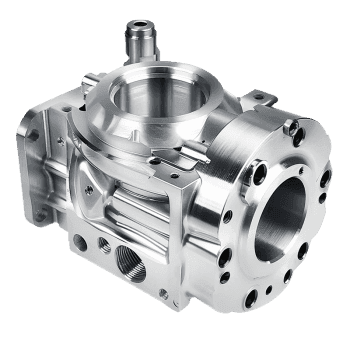

Aerospace Engine Fuel Injector Nozzle

Ultra-precision CNC machining overcomes the challenges of work-hardening, high-temperature alloys like Inconel 718 to achieve flawless micro-features and flawless internal surfaces—delivering reliable, high-performance components for critical aerospace fuel systems.

| Capability | Details / Specifications |

|---|---|

| Part Name | Aerospace Fuel Injector Nozzle |

| Key Material | Inconel 718, Titanium Alloy, High-Temperature Superalloys |

| Critical Challenge | Micron-level orifice drilling (<0.2mm) with severe work hardening and tight surface finish requirements |

| Core Process | 5-Axis CNC Milling & Ultra-Precision Micro-Drilling |

| Surface Finish | Internal Ra < 0.2 μm (via Abrasive Flow & Electrochemical Polishing) |

| Achievable Tolerance | ±0.005 mm (Micro-hole diameter & positional accuracy) |

| Quality Assurance | 100% Orifice inspection with Industrial Microscope & Air Gauge |

.5fc2ccf0.webp&w=2048&q=75)

.e845ae5b.webp&w=2048&q=75)