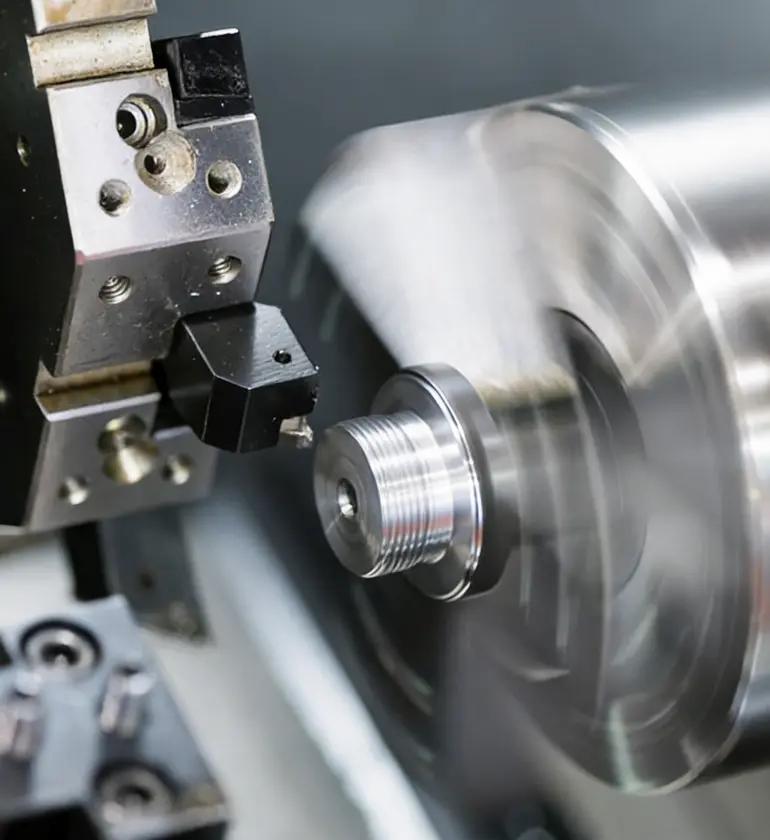

CNC Sliding Head Machining

Achieve the perfect blend of efficiency and simplicity with versatile CNC turning. This is a reliable, cost-effective solution for standard shafts, discs, and sleeves.

Get Quote

Get an instant quote today.

Get instant pricing, project lead times, and DFM feedback

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

File size: 15MB

Trusted by Engineers and Purchasing Leaders at the World's Most Successful Companies

LS Manufacturing has delivered reliable experience to over 28,000 customers by producing more than 250,000 complex parts

Utilize on-demand CNC turning to obtain precision metal and plastic components tailored to your project needs. Supported by advanced equipment and skilled technicians, we deliver high-quality custom prototypes and production parts with consistent accuracy—no matter the complexity.

Achieve the perfect blend of efficiency and simplicity with versatile CNC turning. This is a reliable, cost-effective solution for standard shafts, discs, and sleeves.

Get Quote

Working with ultra-thin, long parts? Swiss-type turning delivers unmatched precision, perfecting high-volume production of micro-components.

Get Quote

For intricate, integrated components, our multi-axis turning-milling centers are the ultimate solution. Consolidate processes and bring your most complex designs to life in a single setup.

Get Quote

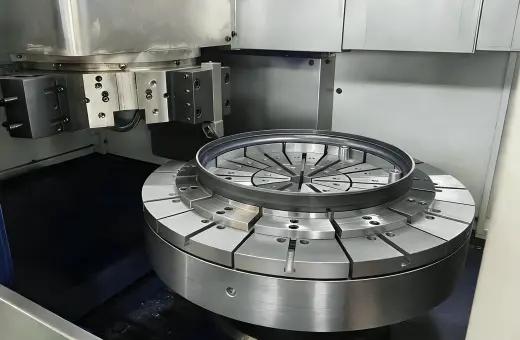

For large-diameter, heavy-duty workpieces, vertical lathes provide unmatched stability. They are the robust choice for machining giant discs, rings, and plates.

Get QuoteSpeed up design validation with our fast-turn CNC turning. We produce precision prototypes and functional test parts quickly, helping you iterate designs and confirm manufacturability before full-scale production.

Learn MoreScale seamlessly from pilot batches to large-scale runs. Our stringent process controls and automated workflows ensure consistent quality, tight tolerances, and reliable delivery—whether you need dozens or thousands of parts.

Get Instant QuoteWe precision‑turn a wide selection of machining‑grade metals and high‑performance plastics to meet your exact specifications. From aerospace‑grade aluminum to medical‑compatible PEEK, our materials are sourced for consistency and machined for reliability—supporting everything from rapid prototypes to certified production parts. Explore our full material library to find the optimal solution for your project's strength, weight, thermal, and cost requirements.

Aluminum offers an exceptional strength-to-weight ratio, outstanding machinability for complex geometries, and strong corrosion resistance. It is a premier choice for high-performance applications in aerospace, automotive, and consumer electronics, where reducing weight without compromising durability is critical.

ABS provides high strength and impact resistance with good heat tolerance, making it ideal for injection molding and machining durable, functional components in consumer electronics, automotive interiors, and structural prototypes.

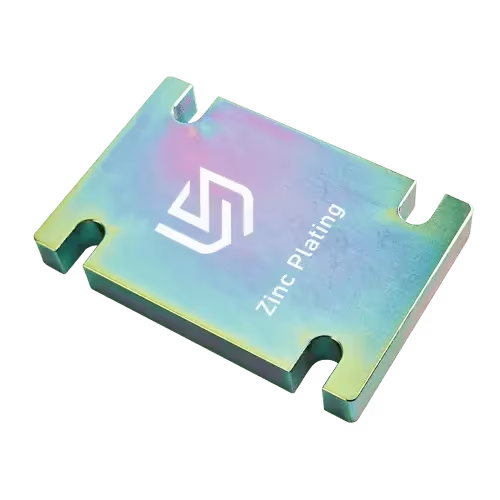

Elevate the performance and appearance of your turned parts. Our specialized finishes improve wear and corrosion resistance, enhance dimensional stability, and provide a refined look—ensuring your components are both durable and professionally finished.

A chromate-based chemical conversion coating primarily for aluminum. It creates a thin, conductive layer that provides excellent corrosion resistance and serves as an ideal substrate for paint adhesion. It is a lightweight, economical alternative to anodizing, widely specified in aerospace, automotive, and military applications for corrosion protection and electrical conductivity.

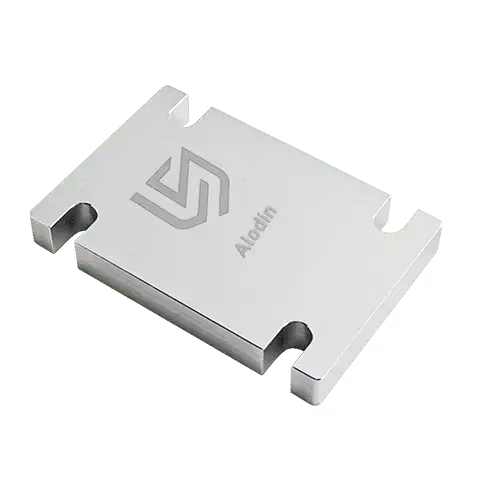

A Type II anodizing process that builds a hard, transparent, and glossy oxide layer on aluminum. It significantly increases surface hardness and corrosion resistance while enhancing the metal's natural luster. Available in a wide spectrum of permanent colors, it is essential for consumer electronics, automotive trim, and architectural components demanding durability and a premium appearance.

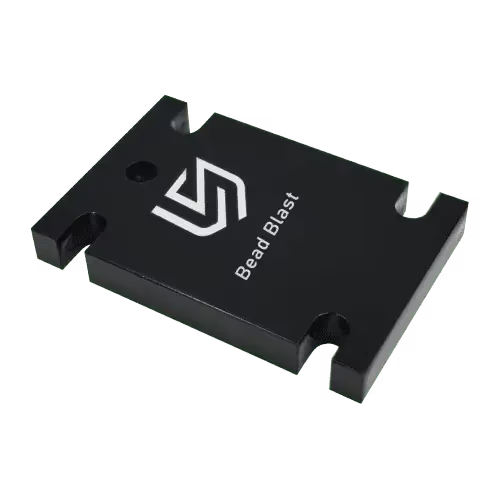

A mechanical finishing process that propels fine media (e.g., glass beads) at high pressure to clean, texture, or matte a surface. It effectively hides minor tool marks, creates a uniform, low-glare satin finish, and provides an optimal key for subsequent painting or coating. Ideal for enclosures, handles, and parts requiring a clean, consistent, non-reflective aesthetic.

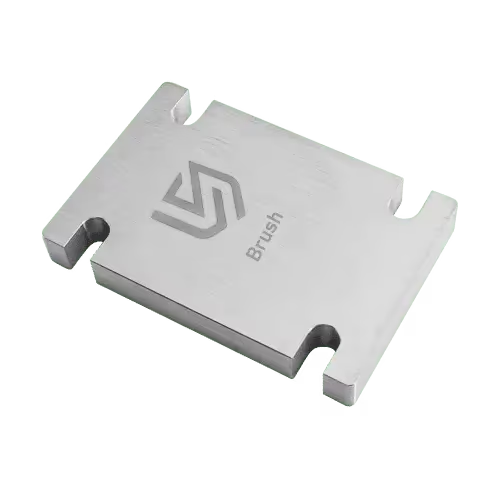

Creates a consistent, unidirectional satin grain on metal surfaces through precision abrasive brushing. This finish masks fingerprints and light scratches, offers a refined tactile feel, and reduces light reflection. It provides a premium, non-glare appearance for consumer-facing components like appliance panels, architectural hardware, and electronic bezels.

An immersion process where a charged part is coated with a paint film drawn from a water-based solution through electrophoresis. It provides exceptional, uniform coverage—including edges and recesses—with superior corrosion resistance. Primarily used as a primer or single coat for automotive frames, agricultural equipment, and high-durability industrial components.

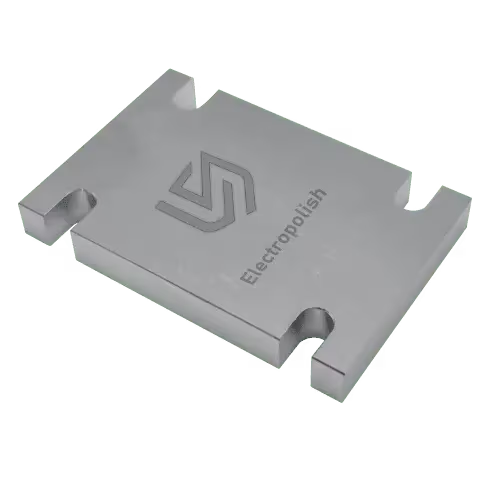

An electrochemical process that removes a microscopic layer of material, smoothing micro-peaks and brightening the surface. Beyond achieving a brilliant, clean finish, it passivates stainless steel and other alloys, drastically improving corrosion resistance, decontamination, and cleanability. Critical for medical implants, semiconductor tools, pharmaceutical, and high-purity fluid systems.

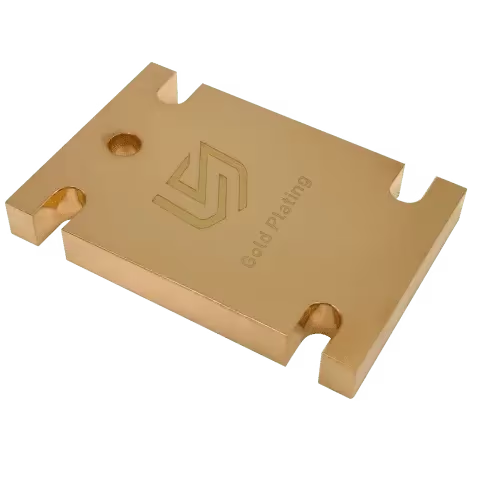

An electroplating process that deposits a thin, adherent layer of gold onto a substrate. It provides superior corrosion resistance, excellent electrical conductivity, and a luxurious, decorative appearance. Used for high-reliability electrical connectors, RF shielding, commemorative items, jewelry, and aerospace components where performance, solderability, or aesthetics are paramount.

The surface finish directly from the CNC machine, characterized by visible, consistent tooling marks. It is the most cost-effective and fastest option, with no added processing time. Ideal for non-visible functional components, internal prototypes, and applications where minimizing cost and lead time is the highest priority over cosmetic appearance.

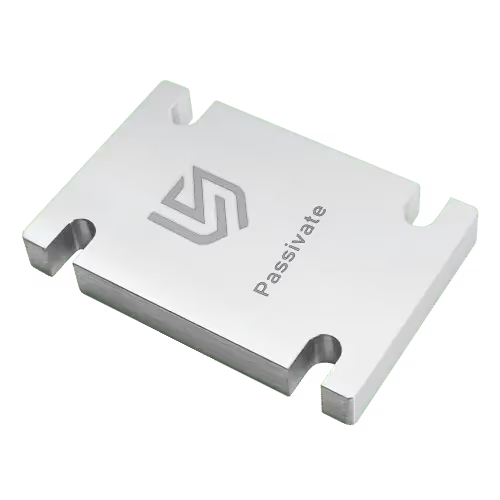

A chemical treatment for stainless steel that removes free iron from the surface and promotes the formation of a stable, inert chromium oxide layer. This process maximizes the alloy's natural corrosion resistance without altering part dimensions. A mandatory step for medical instruments, food processing equipment, and marine components to prevent rust and contamination.

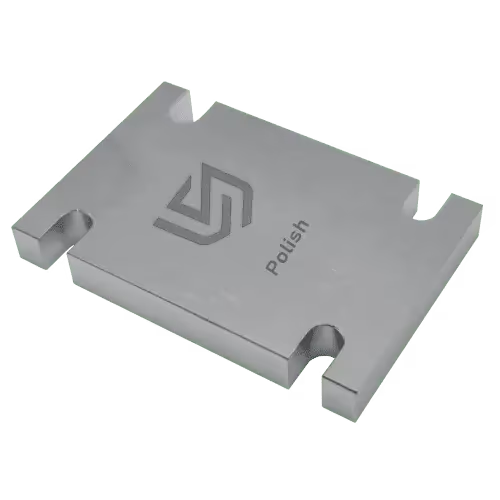

A progressive mechanical abrasion process that refines a metal surface to a smooth, high-gloss, or mirror finish. It dramatically reduces surface roughness (Ra), improving cleanability, light reflection, reducing friction, and elevating visual appeal. Standard for luxury goods, food-grade equipment, optical components, and architectural features.

A specialized post-processing technique for thermoplastics (like ABS, PC, PMMA) that uses solvent vapors to gently melt the surface layer. This eliminates layer lines and microscopic imperfections, resulting in a crystal-clear, glossy, and smooth finish that enhances optical clarity and chemical resistance. Ideal for clear lenses, light guides, and display models.

An electrochemical process that deposits a protective zinc coating on steel or iron substrates. The zinc acts as a sacrificial anode, providing galvanic corrosion protection. It can be supplemented with various chromate conversions (clear, blue, yellow, black) for added resistance and color. A cost-effective and reliable solution for fasteners, brackets, automotive parts, and hardware.

Leverage our extensive network of ISO-certified CNC workshops across China to accelerate your supply chain. We integrate advanced machining centers, grinders, EDM, and automated lines to deliver precision parts with shortened lead times, clear communication, and dependable global logistics—from prototype to production.

LS Manufacturing partners with leading companies across the automotive, aerospace, medical, electronics, and robotics industries. From individual inventors to global enterprises, we deliver precision CNC Turning machining and manufacturing solutions trusted for quality and reliability worldwide.

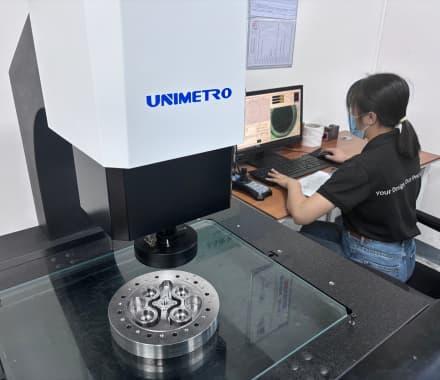

As an ISO 9001 certified partner, we machine CNC turned parts to meet your most stringent specifications, ensuring perfect fit and reliable function. Our standard tolerances adhere to ISO 2768-m for metals and ISO 2768-c for plastics, with precision capabilities reaching ±0.005 mm where your design demands it.

| Description | Specifications & Capabilities |

|---|---|

| Maximum Part Size | Up to 500 mm in diameter and 1500 mm in length as standard. Larger dimensions can be accommodated with specialized equipment and fixturing. |

| Minimum Part Size | Parts as small as 1 mm in diameter can be machined, depending on material properties and geometric complexity. |

| General Tolerances | Standard machining holds ±0.01 mm. Tighter tolerances down to ±0.005 mm are achievable on demand, based on material and part design. |

| Lead Time | Standard delivery in 3–7 business days for most orders. Expedited services are available, reducing lead time to 24–48 hours for urgent projects. |

Engineer your parts for reliable, cost‑effective manufacturing. These key dimensions help prevent tool stress, maintain accuracy, and ensure smooth production—whether you're prototyping or scaling to volume.

Minimum internal radius of 0.5 mm. Larger radii (e.g., 1 mm or more) improve tool access, reduce stress concentration, and enhance part durability.

External/internal threads can be precisely cut.

Standard sizes start at M1.6.

Ensure thread length ≥ 1.5× diameter for stable, secure assembly.

For metals: 0.8 mm; for plastics: 1.5 mm. Adequate thickness prevents distortion during machining and ensures part strength.

Minimum character height: 2 mm.

Depth: 0.5 mm. These dimensions guarantee clear, lasting identification after turning and finishing.

Minimum diameter: 0.5 mm. For deep holes, maintain a diameter‑to‑depth ratio ≤ 1:10 to avoid tool deflection and preserve hole quality.

Your success depends on reliable parts. Our CNC turning services deliver precision‑turned components with a 90% first‑pass yield, supporting both prototype validation and production runs.

Our ISO 9001 certified turning facilities, together with ISO 13485, ISO 14001, and IATF 16949, meet the highest international standards for quality management, environmental responsibility, and industry‑specific compliance.

With more than 30 quality engineers and over 20 advanced inspection tools—including roundness testers, surface roughness gauges, and handheld 3D scanners—we ensure every turned part meets exact dimensional, concentricity, and finish specifications.

From raw bar stock to final inspection, each stage follows documented turning‑specific quality procedures. Full traceability and real‑time updates give you complete confidence in every cylindrical or contoured part, delivered anywhere in the world.

Choose LS Manufacturing for your CNC turning needs and experience our commitment to quality through our rigorous quality control processes. Contact us today to discuss your project and see how we can help you achieve your goals.

LS Manufacturing provides precision CNC turning solutions that meet the demanding standards of various industries. Our commitment to advanced processes and rigorous quality control ensures we deliver reliable prototypes and production parts tailored to your specific requirements.

We specialize in tight‑tolerance turning, holding dimensions to ±0.01 mm for consistent fit and performance. Every part undergoes rigorous inspection to ensure it meets your exact specifications.

Our streamlined workflow and modern turning centers enable rapid turnaround, from prototype to volume production. We help keep your projects on schedule with predictable, on‑time delivery.

From initial design review to final production, our engineers provide actionable DFM feedback and material guidance. We partner with you to optimize manufacturability, reduce costs, and ensure part reliability.

A customer's words mean more than ours see what our satisfied customers have said about how we fulfilled their requirements.

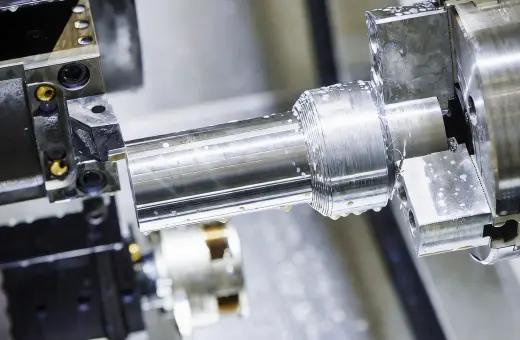

CNC turning is a precise subtractive manufacturing technique that transforms bar stock into accurate cylindrical components. The process begins with your CAD design being translated into machine code via CAM. A cutting tool is then programmed to follow precise paths, removing material as the workpiece rotates, resulting in consistent, high-quality parts.

Upload your CAD model. Our engineers program the optimal tool paths and speeds for your specific material and design.

The raw material is securely clamped in the lathe's chuck, and pre‑calibrated tools are loaded.

The part rotates at high speed while cutting tools shape it, performing operations like facing, turning, drilling, and threading.

Parts are deburred, finished as specified, and undergo stringent dimensional inspection to ensure they meet your tolerances.

CNC turning delivers unmatched precision, repeatability, and efficiency for manufacturing rotationally symmetric parts. By automating the machining process, it enables faster lead times, consistent quality, and greater design flexibility—helping you reduce costs, meet tight deadlines, and scale production with confidence.

High Precision & Tight Tolerances: Achieve tolerances down to ±0.01 mm, ensuring perfect fit and reliable assembly in demanding applications.

Rapid Turnaround & Scalability: Automated workflows support fast prototype delivery and seamless volume scaling to accelerate your production cycle.

Programming Flexibility: Easily adapt to design changes and new part geometries without costly retooling, enhancing project agility.

Consistent Repeatability: Produce identical parts across large batches, maintaining quality and performance in mass production.

Lower Operational Costs: Reduce manual intervention and minimize scrap rates, improving overall cost‑efficiency.

Broad Material Compatibility: Machine a wide variety of metals, plastics, and composites to meet diverse performance and environmental requirements.

Enhanced Operator Safety: Enclosed work areas and automated tool handling create a safer, cleaner machining environment.

As a precision turned-parts manufacturer, LS Manufacturing produces high-accuracy components where dimensional consistency, surface finish, and reliable assembly are critical. Here are common examples of parts we manufacture through CNC turning:

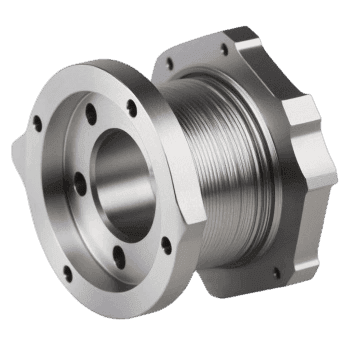

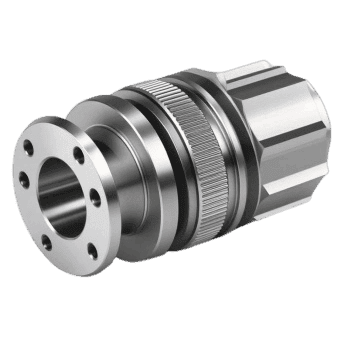

Precision-machined rotating or load-bearing components requiring exact diameters and smooth surface finishes for reliable motion.

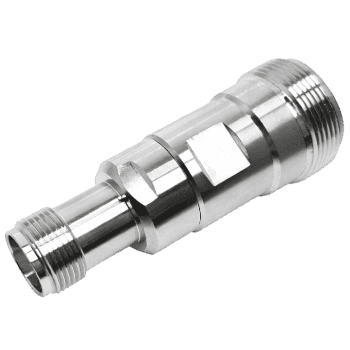

Accurately machined interfaces for piping, pumps, and valves to ensure secure, leak-free connections.

Custom-sleeved inserts that reduce friction and wear between moving parts, demanding precise inner/outer diameters.

Small yet critical alignment or retention parts manufactured to exact dimensions for secure, snug fits.

Ergonomically designed user-interface components where aesthetics, grip, and dimensional accuracy enhance usability.

Conveyor, guidance, or mobility components that require consistent roundness, balance, and low-friction surfaces.

Protective or structural covers with threaded ends, grooves, or precise internal features for assembly.

Stay updated with the latest news and announcements from LS Manufacturing. Explore our latest articles below.

Every successful product starts with a manufacturability check. Upload your CAD file to instantly receive automated DFM analysis on key factors like geometry, tolerances, and wall thickness. For critical projects, our engineers perform a detailed manual review within one business day, providing clear, actionable recommendations on design adjustments, materials, and processes to ensure quality and avoid delays.

We combine in-house manufacturing with a vetted partner network under strict quality standards. Unlike intermediaries, we provide integrated engineering support, from prototyping to full-scale production and packaging. With dedicated project management and a focus on industries like automotive, medical, and electronics, we ensure reliability, consistency, and seamless scale-up for every order.

Lead times vary based on part complexity, quantity, and process. Rapid prototypes (CNC/3D printing) can ship in 2–5 days. Injection molding and low-volume production typically take 2–4 weeks. Submit your design details for an instant quote with a precise timeline.

We provide instant online quotes for standard manufacturing services. Simply upload your 2D or 3D files and select your preferred process, material, finish, and quantity. If your project is more complex, a dedicated engineer will reach out within one business day to review your requirements and prepare a customized proposal.

Yes, we accommodate engineering change requests wherever possible. Minor adjustments during the prototyping stage are generally straightforward, while changes during mass production may affect cost and lead time. Our team will provide a clear impact assessment and assist you in implementing changes with minimal disruption.

We support common 2D and 3D formats, including STEP, STL, IGES, X_T, DWG, and PDF. For best results, please upload complete, dimensioned drawings and specify critical tolerances, surface finishes, and material preferences in your notes.

For prototyping and low-volume orders, we offer no MOQ so you can order as few as one part. For injection molding and large-scale production, MOQ depends on the tooling and process—our team will provide a detailed breakdown during quoting.

We are ISO 9001:2015 certified and comply with industry-specific standards such as ISO 13485 (medical) and IATF 16949 (automotive). We can also provide material certifications, FAIRs, and third-party inspection reports upon request.