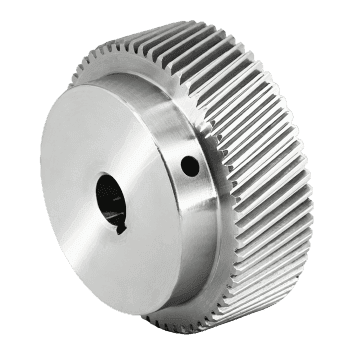

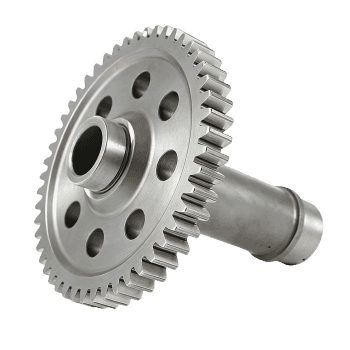

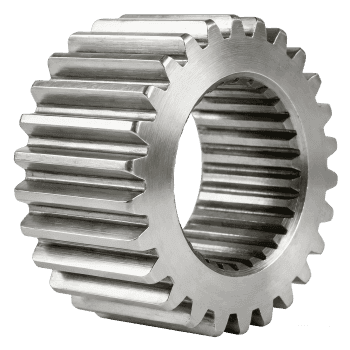

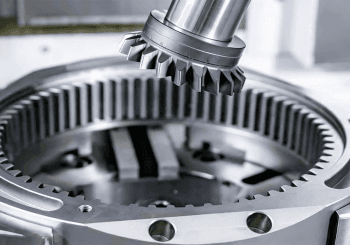

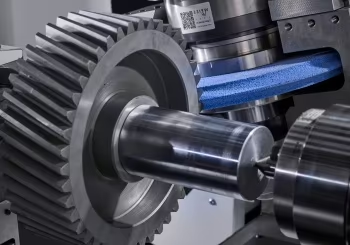

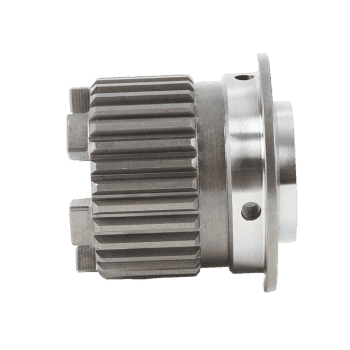

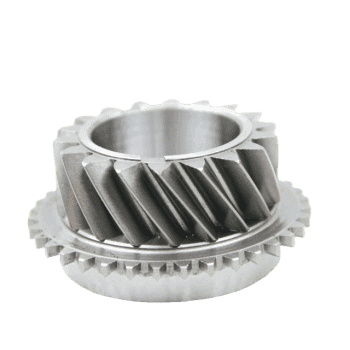

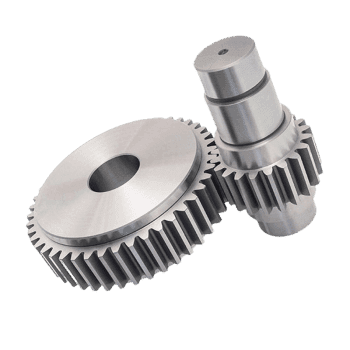

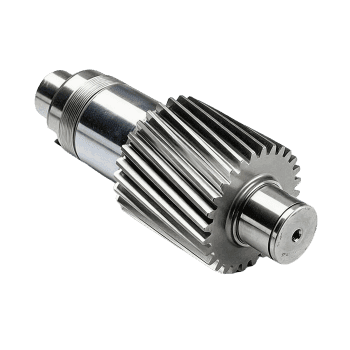

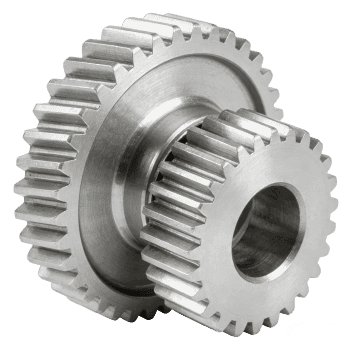

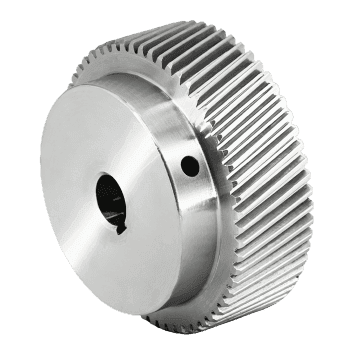

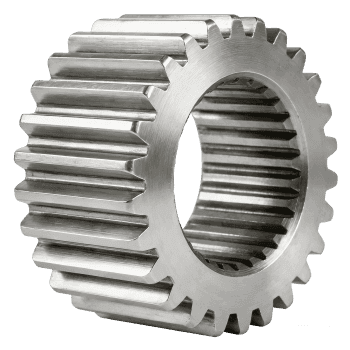

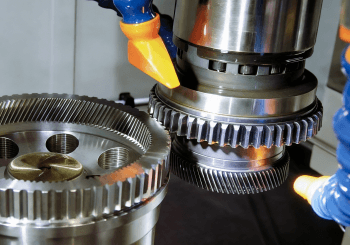

Gear Hobbing

Solve the challenge of maintaining consistency and quiet operation across long production runs. Our gear hobbing service delivers accurately cut teeth with minimal noise and vibration, ensuring your automotive or industrial drives transmit power smoothly and reliability, batch after batch.

CNC Milling Services