Instant Quoting

Instant Quoting Rapid Prototyping

Rapid Prototyping High-Volume Production

High-Volume Production

Instant Quoting for Your Bending Needs

LS Manufacturing provides rapid and accurate quotes for your metal bending projects. With a variety of materials, surface treatments, and high-precision bending capabilities, our quoting system ensures you receive tailored and competitive pricing in minutes, making your project efficient and cost-effective.

Over 40 Material Options: Select from stainless steel, aluminum, brass, carbon steel, and more, providing flexibility and durability for various bending applications.

15+ Surface Finishing Options: Enhance the appearance and performance of bent parts with finishes like anodizing, powder coating, plating, and polishing, with lead times averaging 3-7 days.

Precision Up to ±0.1mm: Achieve tight tolerances and accurate angles for complex bends, ensuring that your parts are precise and functional.

ITAR Registered

ITAR Registered ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

Upload Your Design & Get an Instant Quote Now!

Online Custom Metal Bending Services

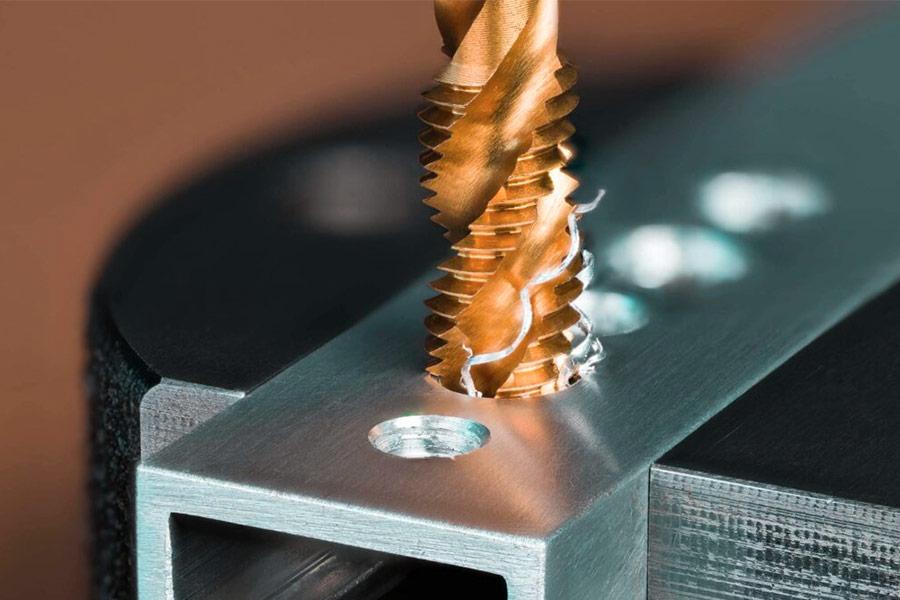

LS Manufacturing provides professional online metal bending services for precision sheet metal and complex structural components. Utilizing advanced CNC bending equipment and specialized process technology, we ensure high angular accuracy and excellent surface quality, ideal for enclosures, brackets and chassis manufacturing.

Instant Quote & Rapid Response:Upload 3D drawings or bend development diagrams for immediate process analysis and real-time pricing

High-Precision Bending:CNC bending machines achieve ±0.1° accuracy, supporting stainless steel, aluminum, carbon steel and other materials

Comprehensive Process Support:Expert guidance in bend sequencing, tooling selection, and springback compensation

Cost-Effective Processing:Competitive pricing through optimized processes and batch production control

Metal Bending Service

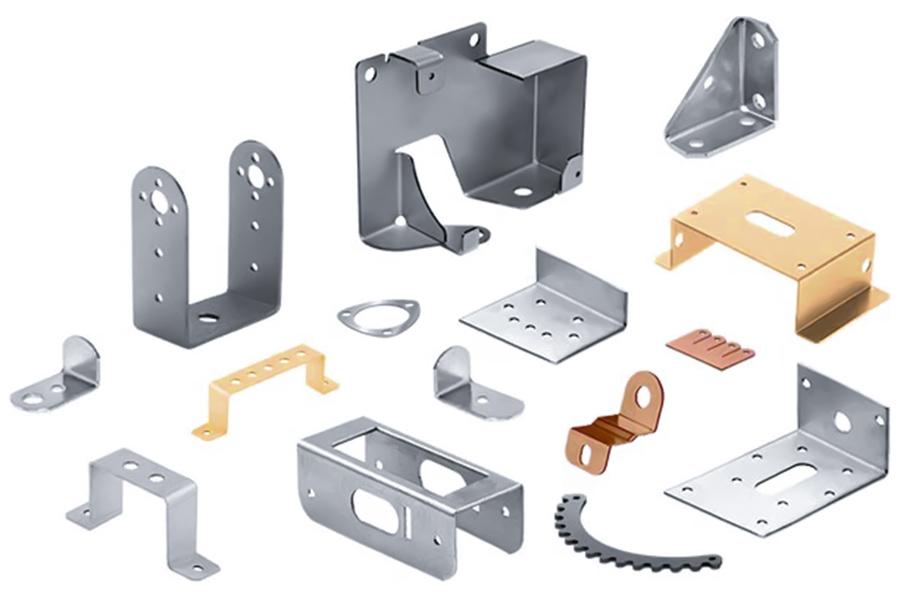

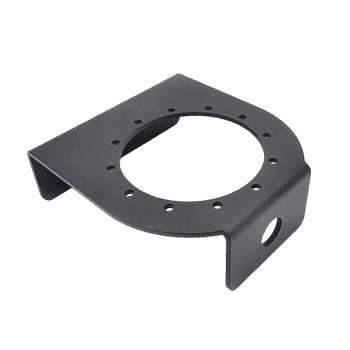

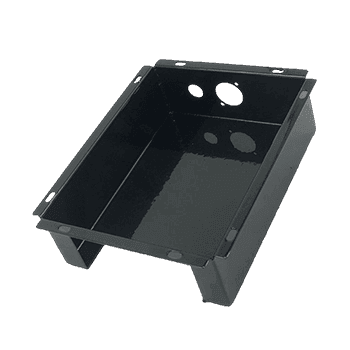

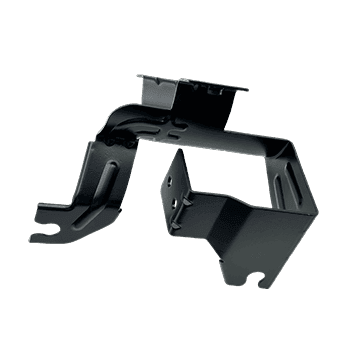

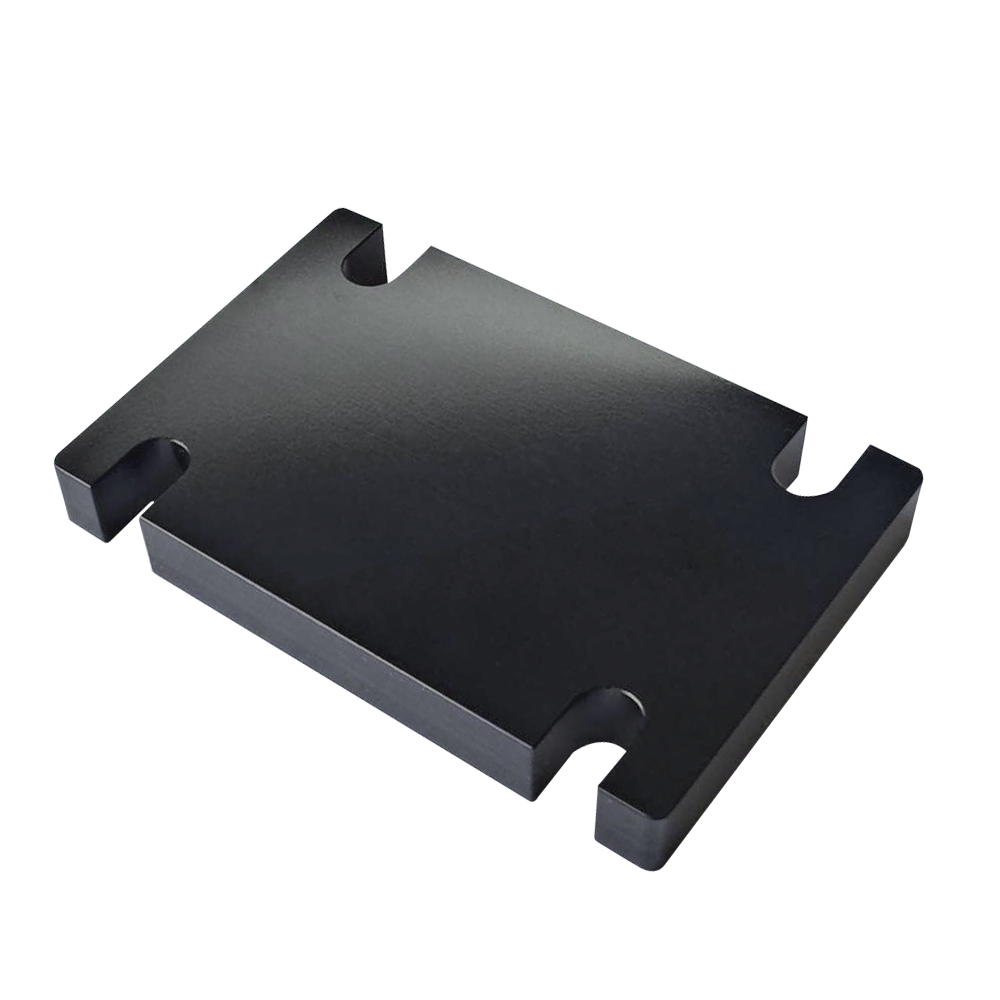

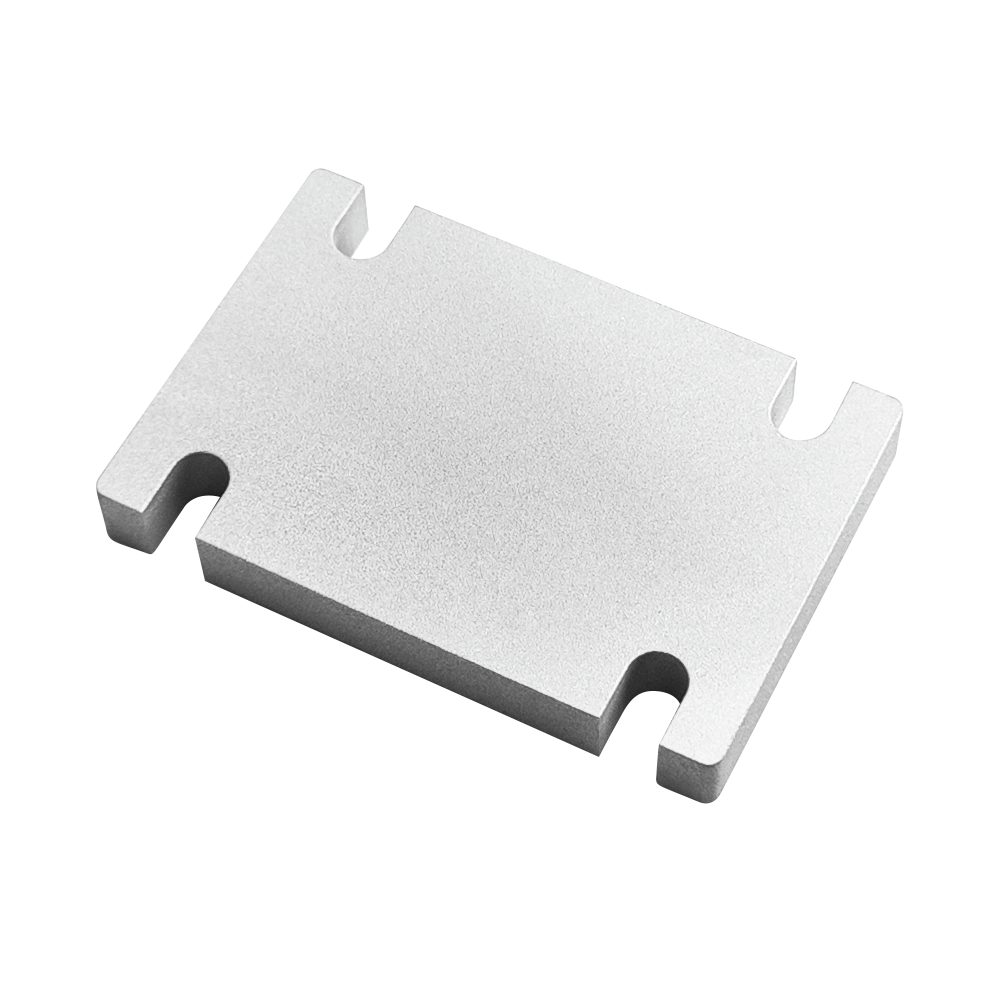

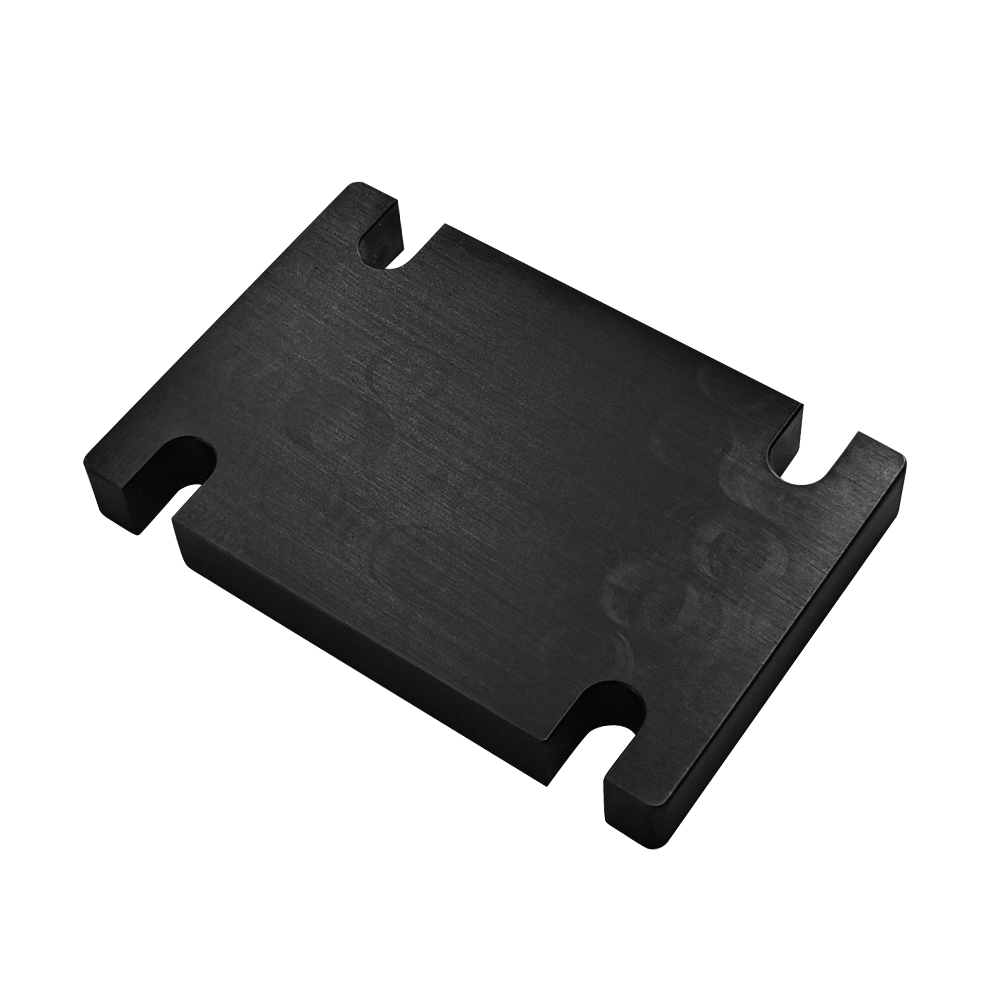

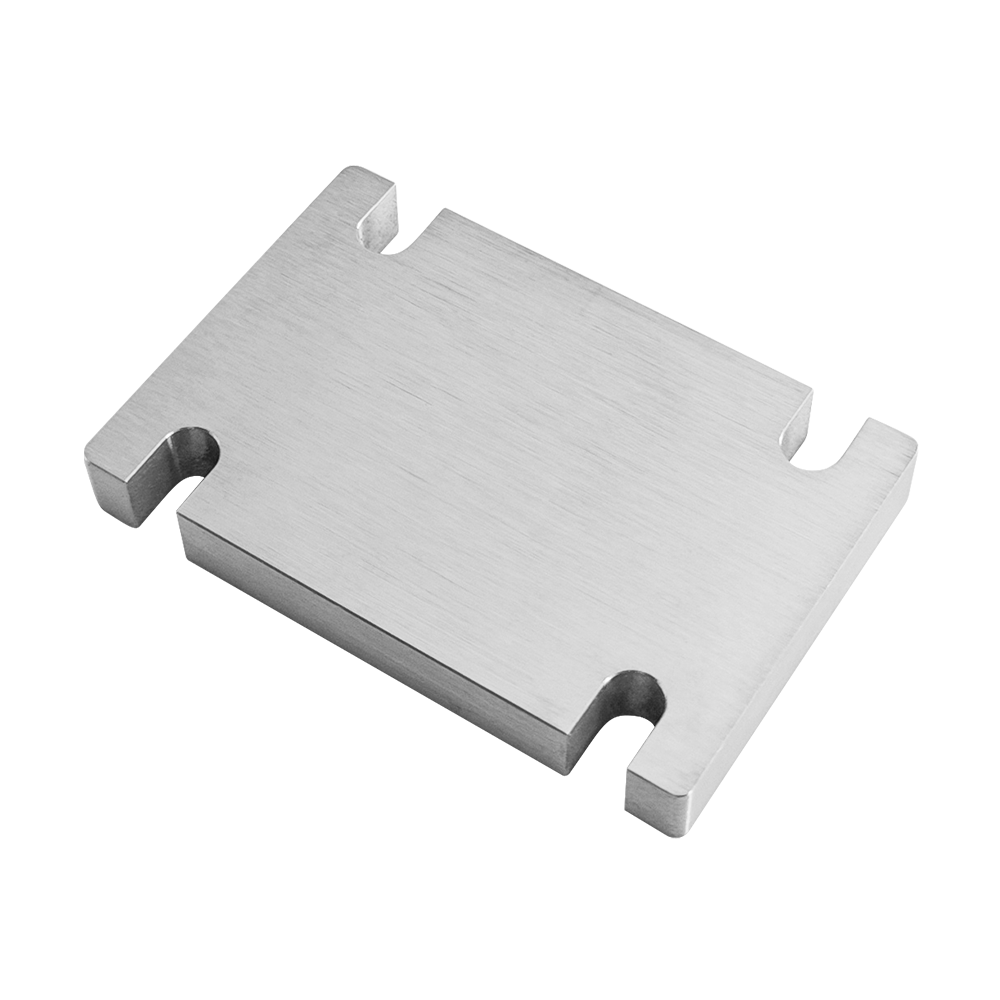

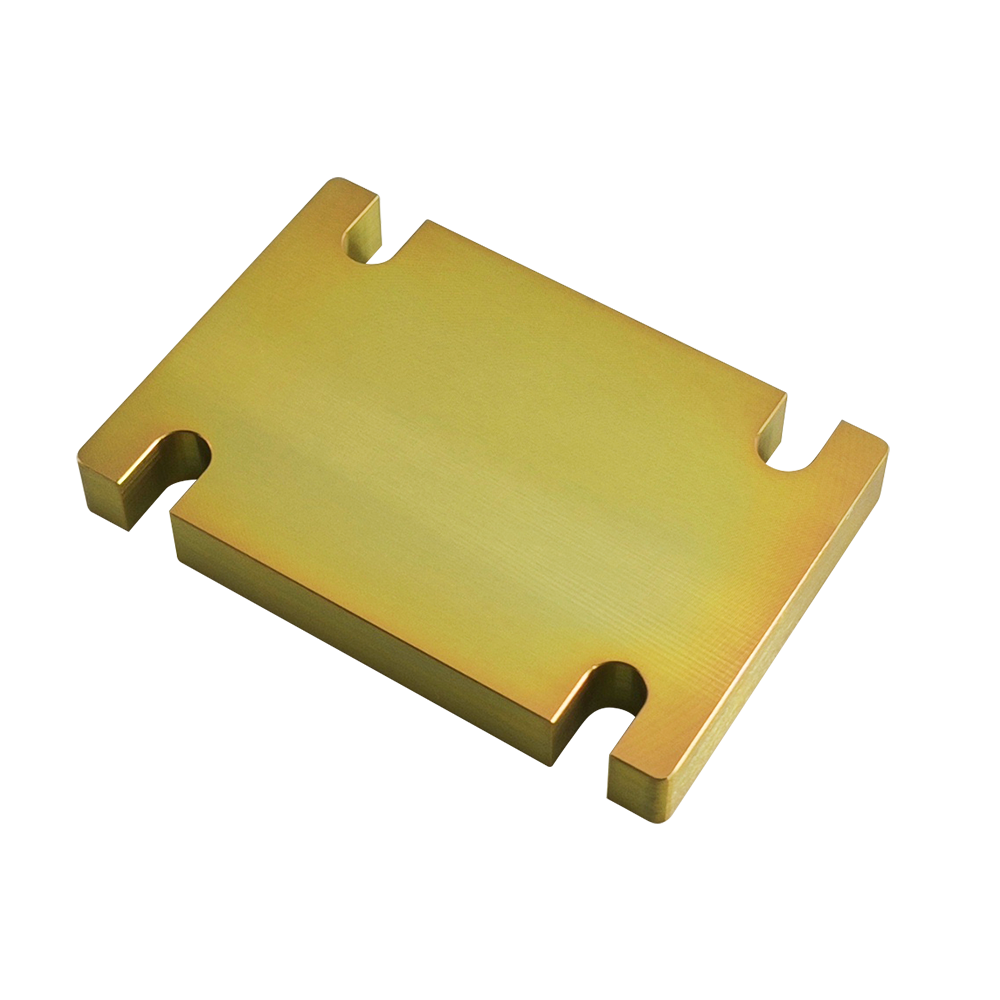

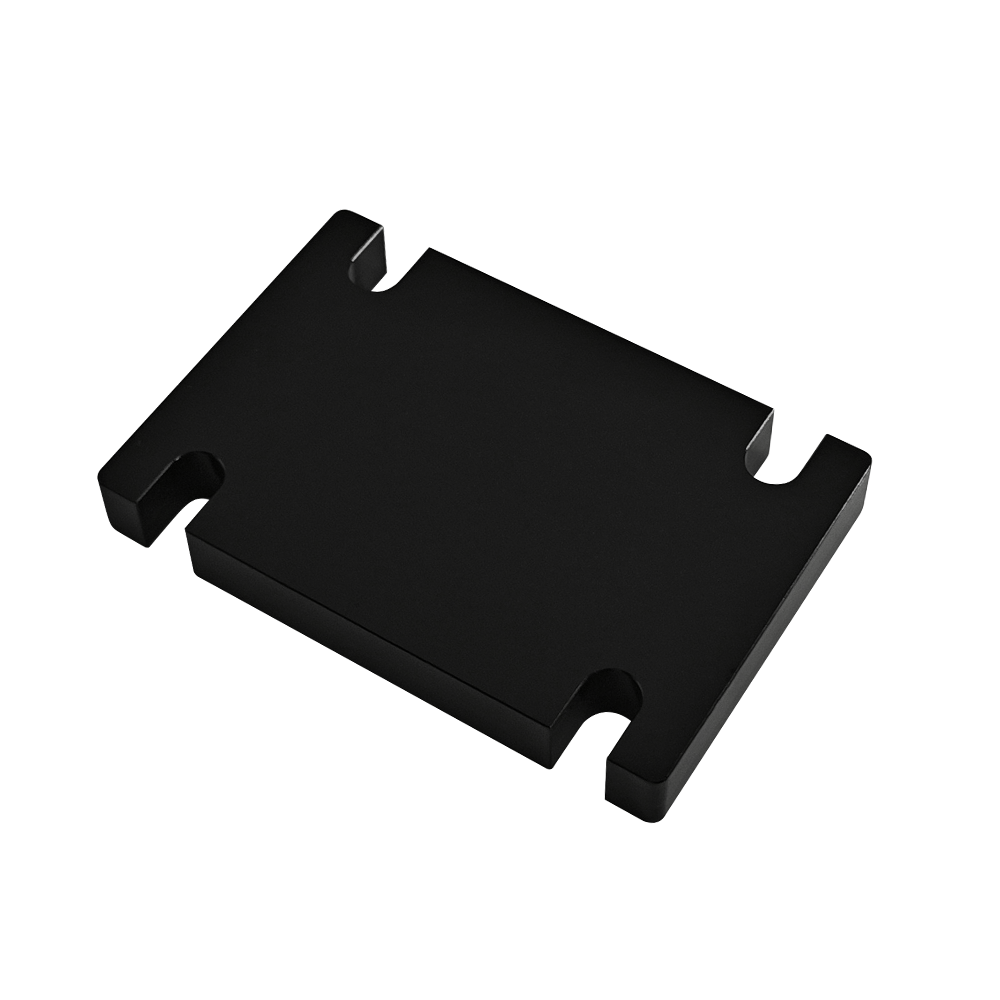

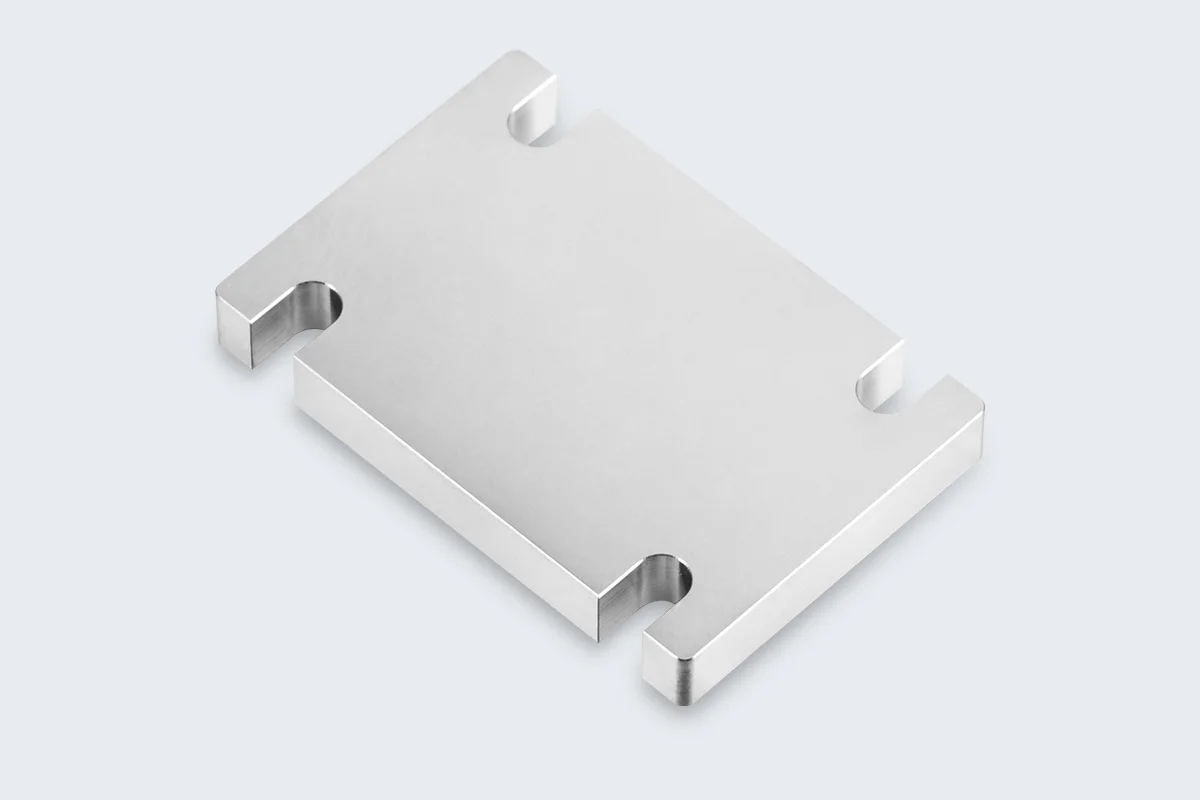

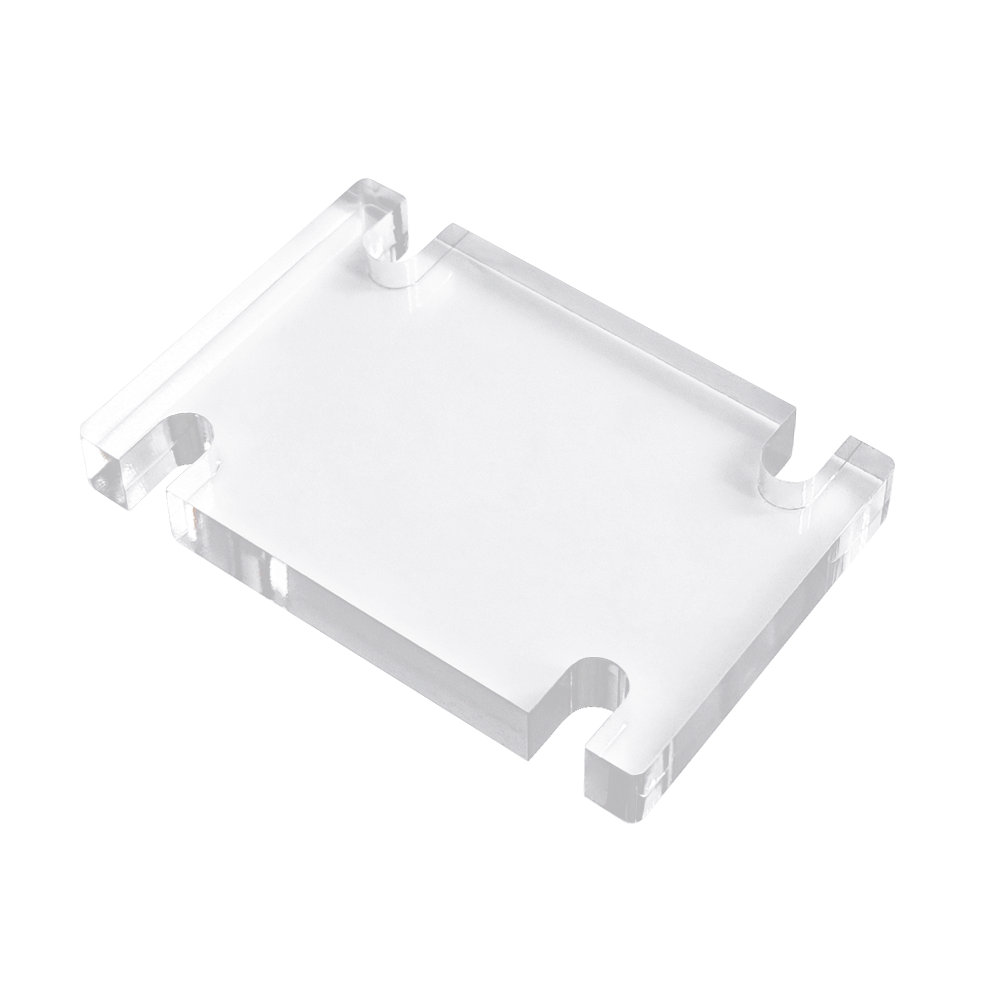

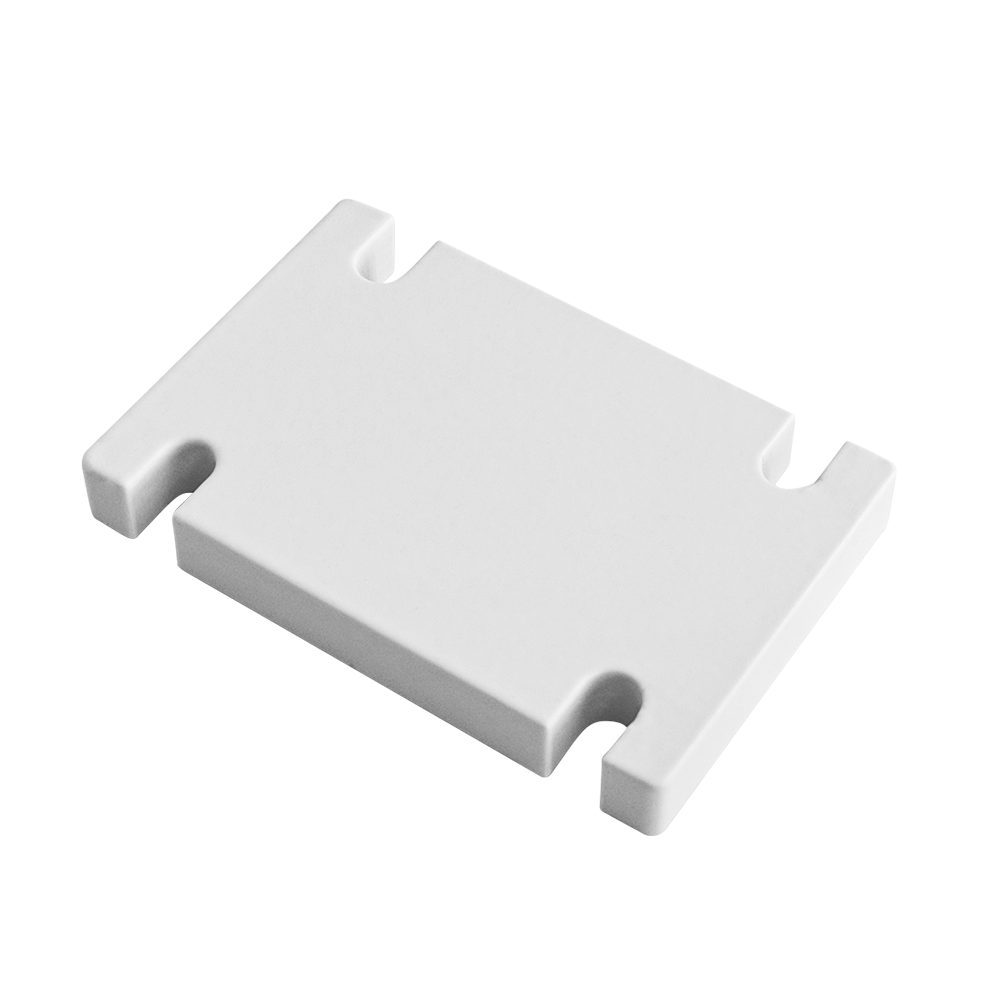

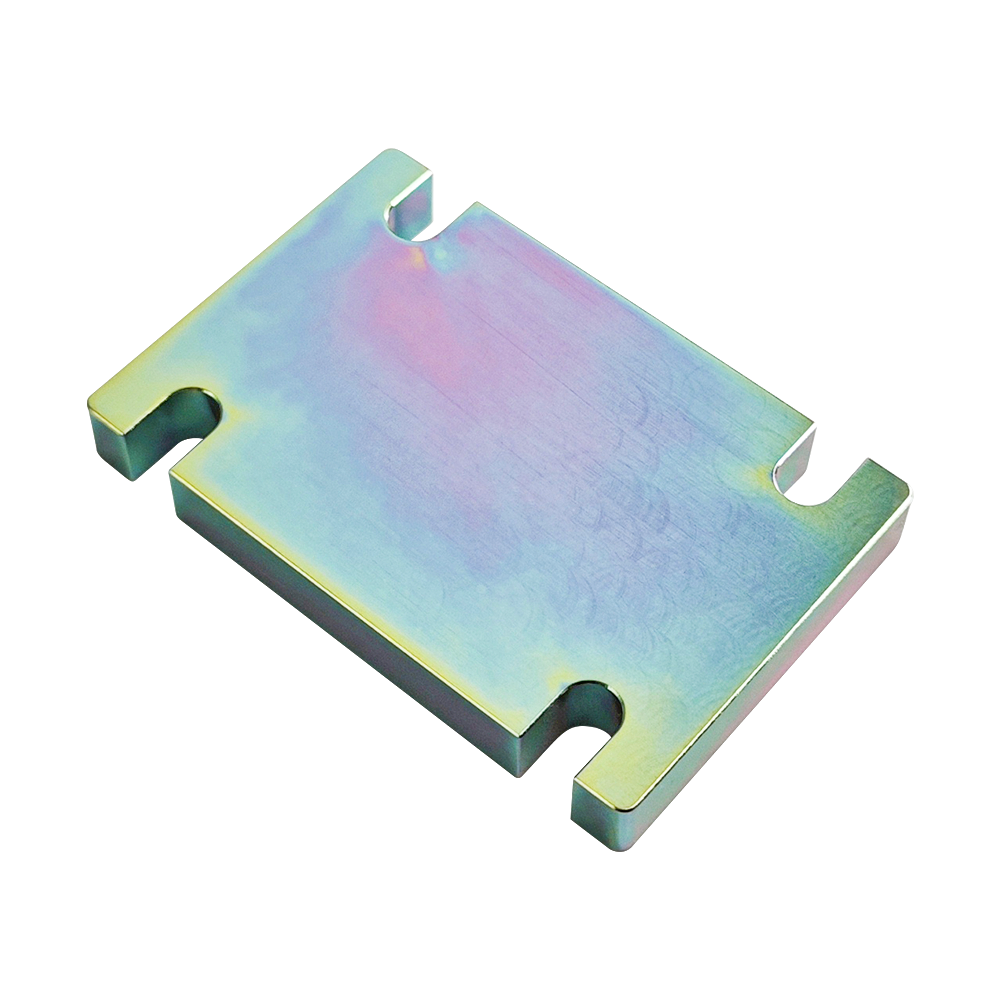

Metal Bending Product Showcase

Our metal bending services deliver high-precision bends for various metals, achieving consistent angles and exact dimensions. Each product demonstrates our expertise in forming complex shapes while maintaining material integrity and strength, ideal for applications requiring durability and precision.

Metal Bending Tolerances

LS Manufacturing offers precision metal bending services with tolerances ranging from ±0.1 mm to ±0.5 mm, depending on material thickness and complexity. Our state-of-the-art equipment ensures consistent bends, delivering high-quality components that meet exact specifications for various industrial applications.

Feature

Description

Maximum Part Size

1.5 m x 1.5m

Metal Bending Forces

Up to 1000 tons

Bending Line Length

Up to 7200 mm

Bending Thickness

Up to 60 mm

General Tolerances

Our metal bending standards depend on ISO 2768.

Bend to edge/hole, single surface

+/- 0.254 mm (+/- 0.010 in.)

Bend Radius

Be equal to material thickness

Bend Angle

+/- 1°

Bend Cutting Area

Up to 4000 mm

Standard Lead Time

3 Business days

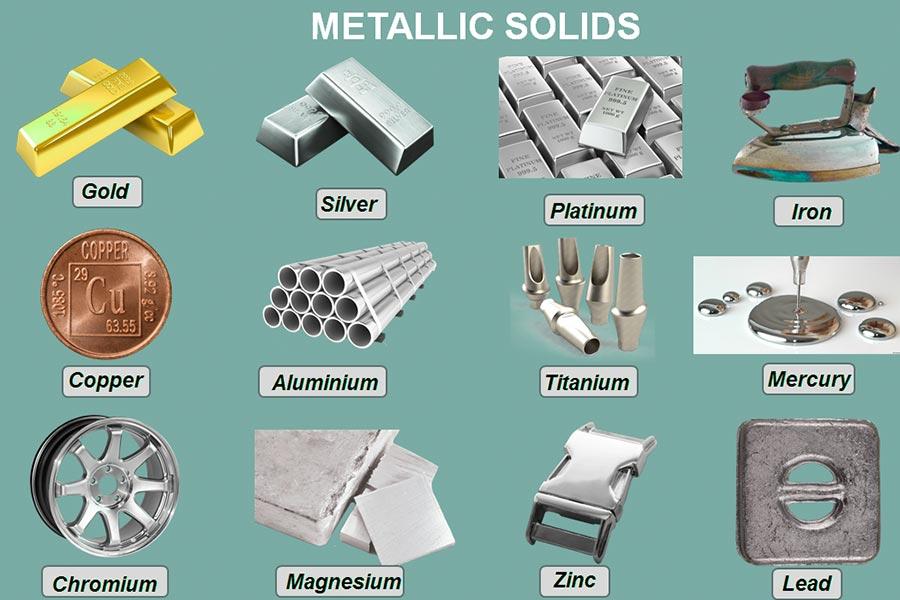

Metal Bending Material Selection

Our bending services are designed to handle a wide range of metals, providing precise and consistent bends to meet your specifications. We work with materials like steel, aluminum, and stainless steel, ensuring the durability and flexibility required for various applications. Each material is selected to maintain structural integrity and avoid cracking during the bending process.

Metals

- Titanium

- Steel

- Stainless Steel

- Magnesium

- Zinc Alloy

- Chromium-Nickel Alloy

- Brass

- Copper

- Aluminum

- Bronze

- Cold Rolled Steel

- Nickel

- Silver-Tin Oxide

- Cast Iron

Titanium is known for high strength, low weight, and corrosion resistance. We process grades like Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-6Al-4V ELI, and Ti-Grade 2, which are widely used in aerospace, medical implants, and sports equipment.

Plastics

- HDPE

- PP

- PE

- PET

- PMMA

- POM

- PPS

- PVC

- FR-4

- PEEK

- ABS

- PC

- PA

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PS

- PTFE (Teflon)

- UPE

- Bakelite

HDPE offers high strength and resistance to impact and chemicals. We support its use in containers, piping, and geomembranes

We offer customization based on your specific material requirements, if you need a material not listed here, our team can source and process ito meet your exact needs

Metal Bending Surface Finishing

Surface finishing in metal bending is crucial to ensuring smooth edges and enhanced durability. Our bending process is precise and efficient, and with options like polishing and coating, we ensure that your bent metal parts not only meet your performance requirements but also have a high-quality finish.

Anodizing Glossy

Anodizing Type I creates a protective oxide layer on aluminum, providing resistance to corrosion and wear.

Bead Blasting

A process that uses a stream of air to propel fine media particles to clean, smooth, or texture a surface.

Black Oxidize

Black oxide is a conversion coating that offers minimal corrosion protection and is used for appearance.

BleadBlasting + Black Anodizing

A process that uses a stream of air to propel fine media particles to clean, smooth, or texture a surface.

Brush

Brushing creates a satin-like texture on metal surfaces, enhancing their appearance and reducing reflections.

Anodize Type II (Glossy, Matte)

.png)

Anodizing Type II creates a protective oxide layer on aluminum, providing resistance to corrosion and wear.

Gold Chromate

Chrome plating provides a bright, mirror-like finish and enhances wear and corrosion resistance.

Polish + Black Anodize

Polishing enhances the surface finish and luster of metals by removing scratches and imperfections.

Polish + Clear Anodize

Polishing enhances the surface finish and luster of metals by removing scratches and imperfections.

Vapor Polish

Vapor polishing is a technique to improve the transparency and smoothness of plastic components.

White Powder Coating - Flat

Powder coating provides a durable and high-quality finish that enhances the appearance and corrosion resistance of metals.

Zinc Plating

Zinc plating applies a protective zinc layer to steel or iron, enhancing corrosion resistance.

Metal Bending Advantages & Features

Our bending services provide precise, high-quality metal forming solutions for various industries. LS Manufacturing offers advanced bending techniques to meet your specific project requirements, from simple bends to complex shapes. Here’s why we are the right choice for your metal bending needs.

Precision Bending with Tight Tolerances

Using advanced CNC press brakes, we achieve high precision and consistency in bending operations, ensuring tight tolerances and high-quality results. This level of accuracy is critical for industries like automotive, aerospace, and electronics where exact measurements are essential.

Fast Lead Times

Our efficient production processes allow us to offer fast turnaround times without compromising quality. We typically deliver bent metal parts within 3-7 days, ensuring your project stays on schedule.

Wide Range of Materials

We specialize in bending a variety of metals, including steel, aluminum, stainless steel, and copper. Whether your project requires lightweight aluminum or heavy-duty steel, we can accommodate your material needs with precision.

Complex Bends and Custom Shapes

Our advanced bending equipment allows us to create both simple and complex shapes with high accuracy. Whether you need standard bends or intricate custom designs, we work closely with your specifications to ensure perfect results.

Scalability for Prototyping and Mass Production

Our bending services are scalable to meet both small prototype runs and large-scale production. We handle orders from a few pieces to thousands of units, ensuring flexibility and efficiency for projects of any size.

Comprehensive Quality Assurance

We implement stringent quality control measures throughout the bending process, ensuring each part meets the required specifications. Our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification and use of advanced inspection tools demonstrate our commitment to delivering precise and reliable bent parts.

Metal Bending Case Studies

Our metal bending services have been successfully utilized across various industries. Below are some examples that demonstrate our capability to deliver high-precision, high-quality bent metal components tailored to specific industry needs:

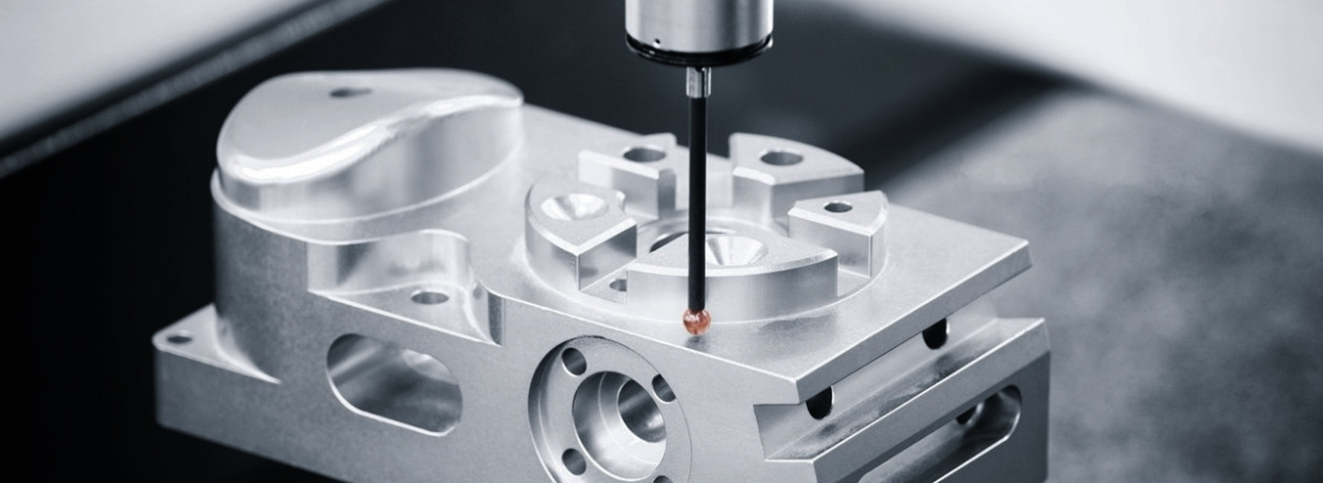

Metal Bending Quality Control

At LS Manufacturing, we ensure precision and consistency in all our bending operations, particularly for metal components. Our advanced bending processes, combined with a rigorous quality control system, guarantee high accuracy, tight tolerances, and reliable performance for various applications, meeting the specific requirements of our customers.

In-Process Inspections

Our quality control begins with in-process inspections, where each part is checked at various stages of production to ensure adherence to design specifications. This proactive approach helps identify and correct any issues early in the manufacturing process.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

We utilize precision measurement tools such as Coordinate Measuring Machines (CMM) and angle gauges to ensure that each bent component maintains tight tolerances and correct specifications. These tools allow us to achieve high levels of accuracy and quality in our bending operations.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification

Our commitment to quality is demonstrated by our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification. This international standard ensures that our quality management system is effective and continuously improving, providing our customers with consistent, high-quality products.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Need Assistance? We're Here for You.

If you have any questions or need assistance, our team is ready to provide support 24/7. Reach out to us through any of the methods below.

We understand that you may have questions about our bending metal fabrication services. Here are some of the most frequently asked questions and their answers to help you better understand our capabilities and processes. If you need further assistance, our team is always ready to help.

What Our Clients Say About Us

A customer's words mean more than ours see what our satisfied customers have saidabout how we fulfilled their requirements.

Metal Bending Latest News

Stay updated with the latest news and announcements from LS Manufacturing. Explore our latest articles below.