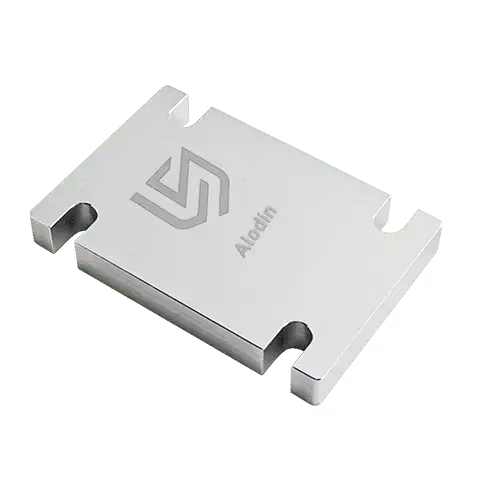

Alodin

A chromate-based chemical conversion coating primarily for aluminum. It creates a thin, conductive layer that provides excellent corrosion resistance and serves as an ideal substrate for paint adhesion. It is a lightweight, economical alternative to anodizing, widely specified in aerospace, automotive, and military applications for corrosion protection and electrical conductivity.