Introduction

Medical Device Industry Services

Advantages & Features

LS Manufacturing's medical device industry solutions offer several key advantages and unique features that set us apart from the competition.

High Precision

Our advanced manufacturing technologies ensure that every part meets the highest standards of precision and accuracy. We achieve tolerances as tight as ±0.005mm, ensuring your parts meet exact specifications and quality requirements. Over 95% of our robotics and automation projects have achieved this level of precision, reducing the need for rework and increasing overall efficiency by 20%.

Quick Turnaround

We offer rapid production times to meet the tight deadlines of the robotics and automation industry without compromising on quality. Our streamlined processes ensure that 98% of orders are delivered on or before the agreed deadline, helping our clients launch their products faster and gain a competitive edge. On average, our clients have reported a 15% reduction in time-to-market for their products.

Comprehensive Material Options

We provide a wide range of materials, including metals, plastics, and composites, to suit various robotics and automation applications. Our material selection ensures that each part meets the specific performance and durability requirements of the robotics industry. We have handled over 50 different types of materials in the past year, demonstrating our versatility and capability to meet diverse client needs.

Cost-Effective Solutions

Our efficient production processes help reduce costs while maintaining high-quality standards. We have optimized our processes to save clients an average of 20% on machining costs, allowing them to allocate resources more effectively and improve their profit margins. Our cost-effective solutions have led to a 25% increase in repeat business.

Expert Support

Our experienced team provides expert guidance throughout the entire manufacturing process, from design to production. Our engineering team has over 20 years of combined experience, ensuring high-quality outcomes and expert advice. We conduct over 30 staff training sessions annually to maintain our cutting-edge capabilities and keep up with industry advancements, resulting in a 15% increase in overall team productivity.

Custom Solutions

We understand that each robotics and automation project has unique requirements. Our team works closely with clients to develop custom solutions tailored to their specific needs. This approach has led to a 30% increase in customer satisfaction and a 20% improvement in project outcomes.

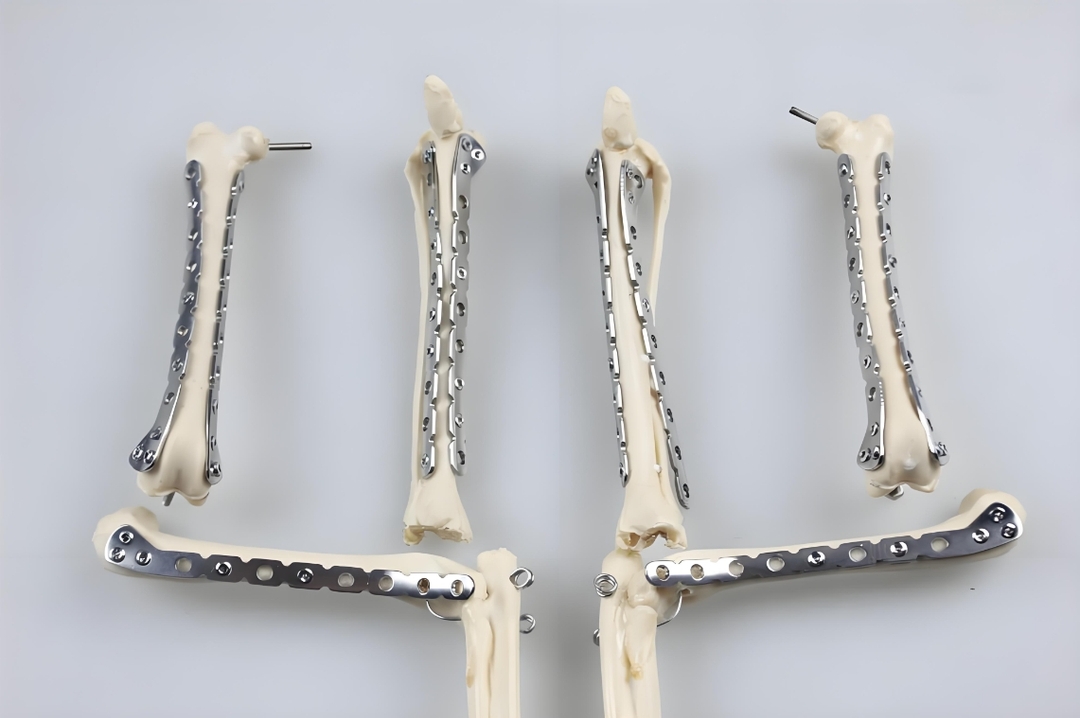

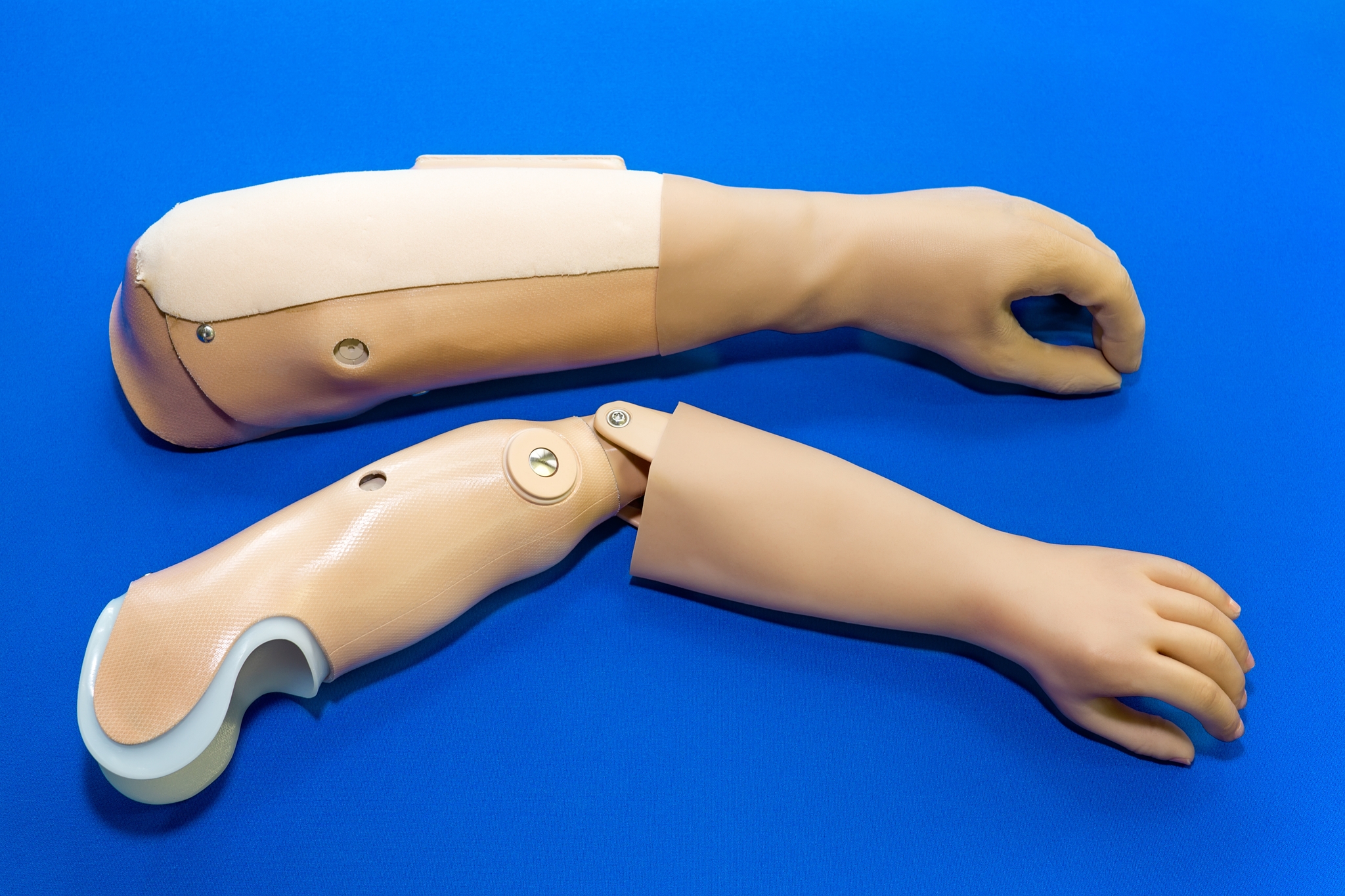

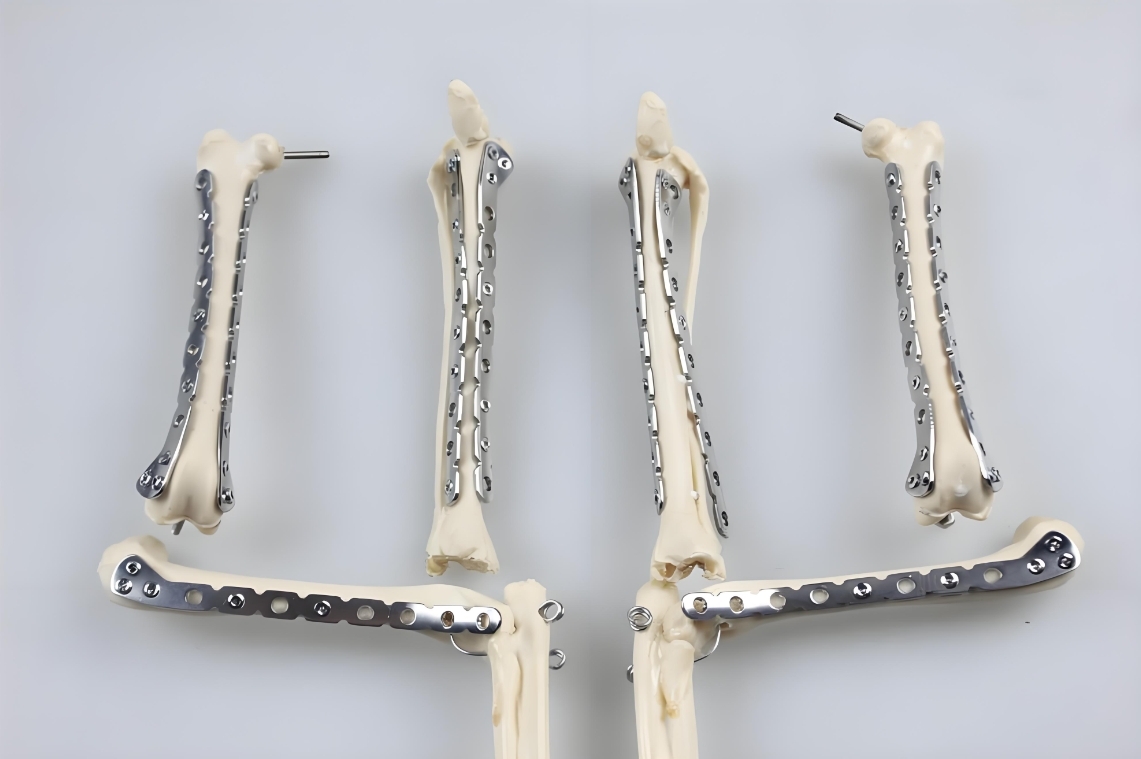

Case Studies

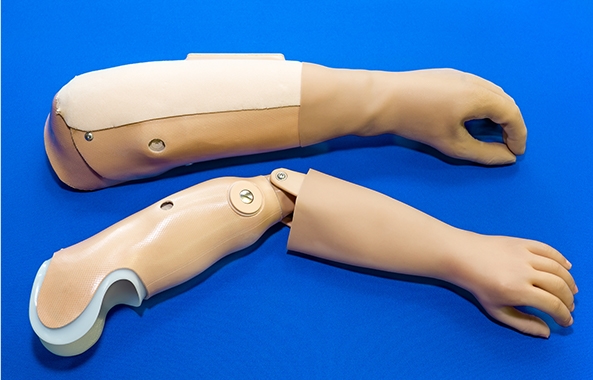

Our CNC milling services have been successfully utilized in various medical applications. Here are some examples that demonstrate our capability to deliver high-quality, precise milled parts tailored to the specific needs of the medical device industry:

Quality Control

At LS Manufacturing, quality is our top priority. We implement rigorous quality control measures throughout the entire CNC milling process to ensure that every medical device part meets the highest standards of precision and reliability. Our comprehensive quality assurance system includes advanced inspection tools and techniques to maintain consistency and excellence in our products.

In-Process Inspections

Our quality control begins with in-process inspections, where each medical part is checked at various stages of production to ensure adherence to design specifications. We conduct over 1,000 in-process inspections monthly, helping to identify and correct any issues early in the manufacturing process, ensuring high-quality output.

Final Inspections

Before any medical part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We perform final inspections on 100% of parts before shipping, using advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

We utilize a range of precision measurement tools, including Coordinate Measuring Machines (CMM), optical comparators, and laser scanners, to accurately measure the dimensions and tolerances of our medical parts. These tools enable us to maintain tight tolerances and high precision in every component we produce, achieving accuracy up to 0.001mm for critical dimensions.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification

Our commitment to quality is demonstrated by our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification. This international standard ensures that our quality management system is effective and continuously improving, providing our customers with consistent, high-quality products. We have been ISO 9001 certified for over 6 years, consistently passing annual audits.

Need Assistance? We're Here for You.

At LS Manufacturing, we are committed to providing you with the best CNC milling services for the medical device industry. Our team is ready to assist you with any questions or concerns you may have. Below are some frequently asked questions and their answers. If you need further assistance, please feel free to contact us.

What Our Clients Say About Us

At LS Manufacturing, we pride ourselves on delivering exceptional CNC milling services that exceed our clients' expectations. Here are some testimonials from our satisfied medical device industry customers who have experienced the quality and precision of our work firsthand.

Latest News

Stay updated with the latest news and announcements from LS Manufacturing. Explore our latest articles below.