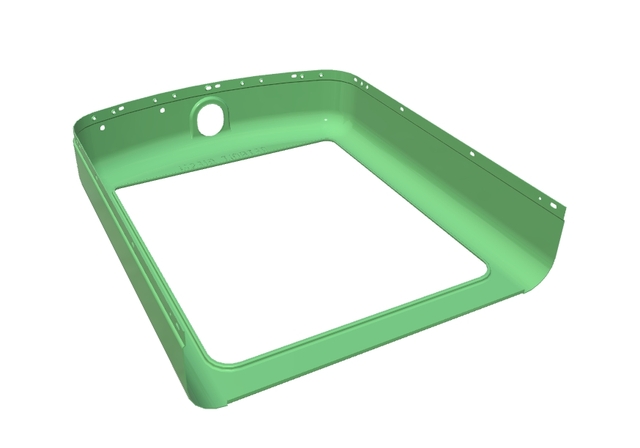

In the realm of modern manufacturing, deep draw stamping has emerged as a critical process, predominantly due to its precision and efficiency. Leveraging advanced deep draw techniques, this form of metal forming demonstrates its prowess by producing complex components with high precision. As industries continue to demand parts that meet stringent specifications, deep draw stamping stands out due to its ability to meet these rigorous requirements while maintaining cost-effectiveness.

Deep draw metal forming is a specialized process where metal sheets are radially drawn into a forming die by the mechanical action of a punch. Considered an evolution over traditional stamping processes, precision deep draw stamping is used to manufacture parts with reduced waste and increased uniformity. These techniques are ideal for producing both large and small components with intricate designs, ensuring high-quality outcomes in industries such as automotive, aerospace, medical devices, and consumer electronics.

LS Hardware Tech Co., Ltd, spearheaded by experienced engineer Nick Zhang, exemplifies excellence in the application of deep draw stamping. With over two decades of expertise, LS has refined its approach to become a trusted partner providing metal stamping services to more than 5,000 clients. The company’s commitment to precision extends far beyond manufacturing—it's a collaboration aimed at bringing clients' ideas to life, utilizing technologically advanced deep draw manufacturing processes that accommodate high-volume needs with unmatched quality and efficiency.

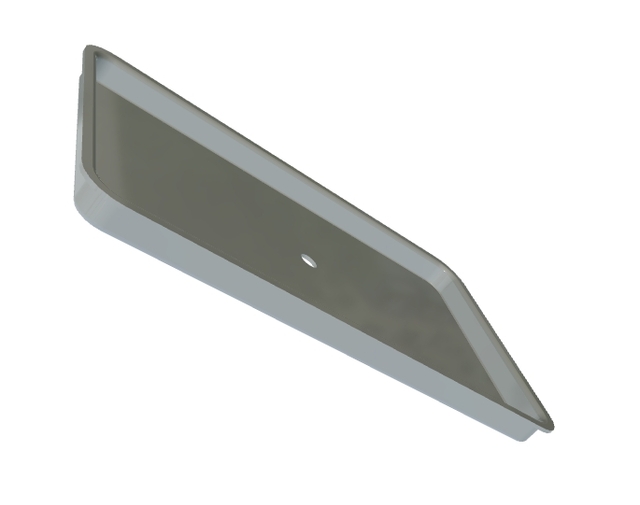

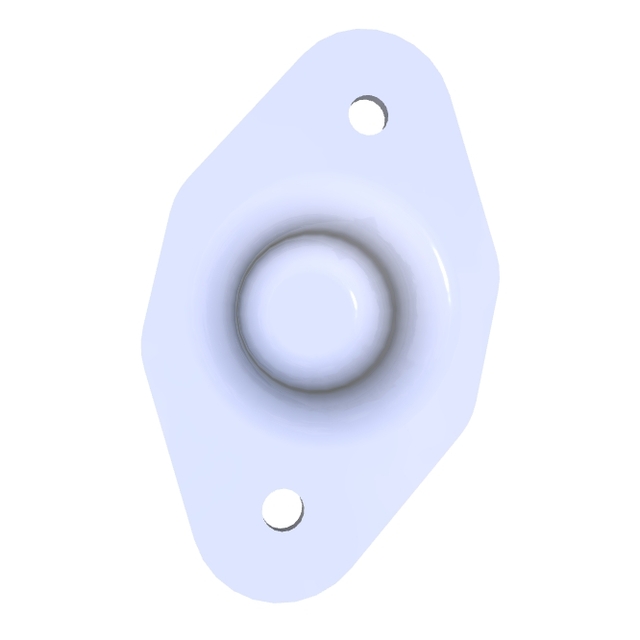

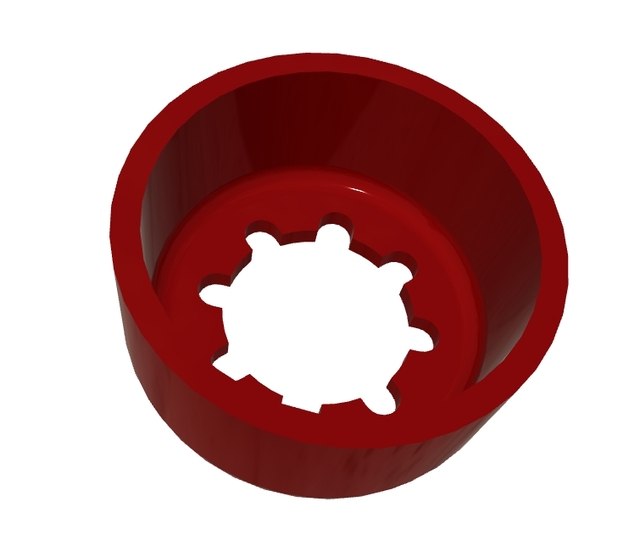

Complementing this robust manufacturing capability is LS's prowess in innovation, evidenced by their latest product, the Push Mount Vibration Damper. This bespoke component is designed with a sleek aesthetic and operational efficiency in mind. The damper, crafted with high-quality materials, is engineered for optimal durability and performance. Its precision design is another testament to the adept application of precision deep draw stamping techniques.

This damper, with its dual-hole mount design, offers easy installation and secure fit, making it highly versatile for use in various sectors such as machinery, automotive, and electronics. It's a quintessential example of how custom deep draw components are revolutionizing industries by reducing noise and vibration effectively. Through sophisticated deep draw techniques, LS ensures that each vibration damper seamlessly integrates into any setup, elevating both functionality and aesthetics.

The company's dedication to quality and technological advancement is further validated by its ISO 9001:2015 certification, which reinforces LS's commitment to maintaining high standards in all of its products and services. With over 100 high-end machining centers, LS Hardware Tech Co., Ltd, not only supports custom deep draw components but also handles the entire lifecycle from prototyping to full-scale production, reflecting its adaptability and efficiency in catering to diverse industry demands.

As a corporation that values innovation and customer satisfaction, LS Hardware Tech Co., Ltd strives to remain at the forefront of technology, constantly refining its processes and capabilities. This foresight ensures they meet the evolving needs of a global client base, reinforcing their reputation in providing reliable manufacturing solutions. Their comprehensive understanding of high-volume deep draw stamping processes positions them as leaders in the hardware manufacturing sector, championing precision and quality in every project they undertake.

In summary, the importance of deep draw stamping cannot be overstated, especially in today’s demanding manufacturing landscape where precision and efficiency are paramount. Companies like LS Hardware Tech Co., Ltd are integral in advancing the manufacturing field by delivering custom deep draw components and metal stamping services that embody the perfect marriage of technology and craftsmanship. Their commitment to innovation, fuelled by deep draw manufacturing expertise, continues to drive industries forward by enabling the creation of robust, high-quality products that meet today’s stringent standards.

Deep Draw Stamping: Precision and Efficiency Redefined

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Stamping, Progressive Die Stamping, Deep Draw Stamping, Hydroforming, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Deep Draw Stamping: Elevating Precision and Design

Deep Draw Stamping: Precision and Efficiency Redefined

Exploring Advanced Deep Draw Stamping Techniques for Precision Engineering

Deep Draw Stamping: Precision Solutions by LS Hardware Tech

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Deep Draw Stamping: Precision & Applications

Deep Draw Stamping: Techniques & Precision Solutions

Deep Draw Stamping: Precision Solutions for Modern Industries