In the world of manufacturing, precision and efficiency are paramount. Among the various techniques that have evolved to meet the demands of modern engineering, deep draw stamping stands out for its ability to create complex shapes and high-quality parts with remarkable reliability. At the forefront of this innovation is LS Hardware Tech Co., Ltd, a company renowned for its expertise in metal stamping processes, particularly deep drawing techniques.

Founded by Mr. Nick Zhang and a team of seasoned engineers, LS Hardware Tech Co., Ltd has established itself as a leader in the hardware and plastic parts manufacturing industry. With over 20 years of experience, the company has honed its skills in producing stamped metal parts that serve a multitude of industries, including automotive, medical devices, consumer electronics, and aerospace. Their deep draw stamping capabilities allow them to offer custom solutions tailored to meet specific client needs. This process is ideal for creating precise metal parts from sheet metal, providing a cost-effective solution for businesses seeking high-quality components.

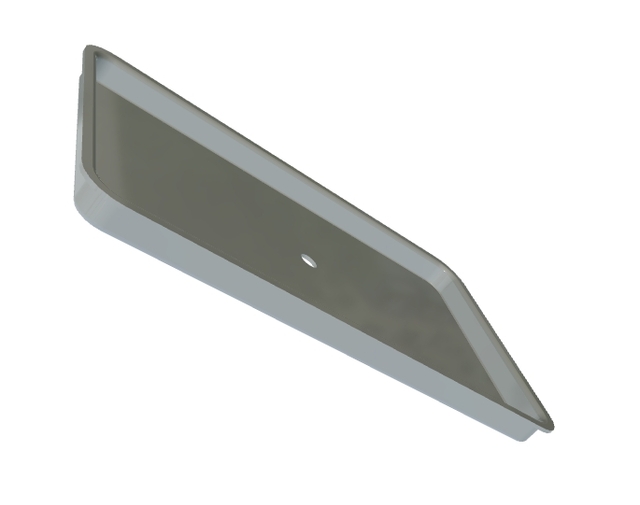

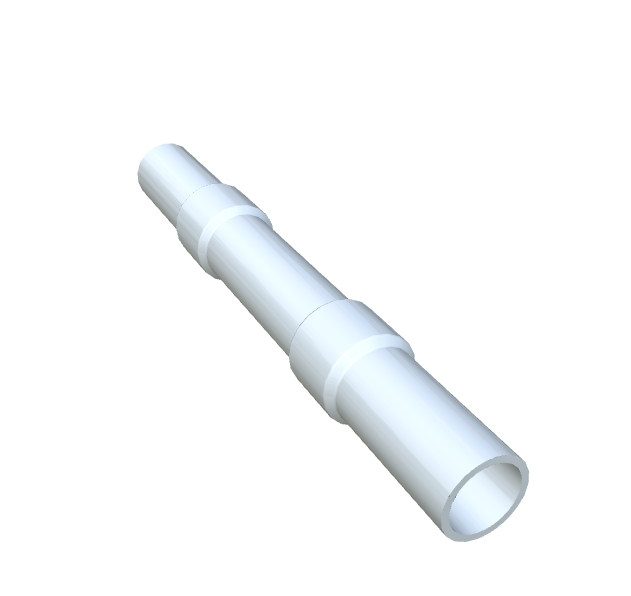

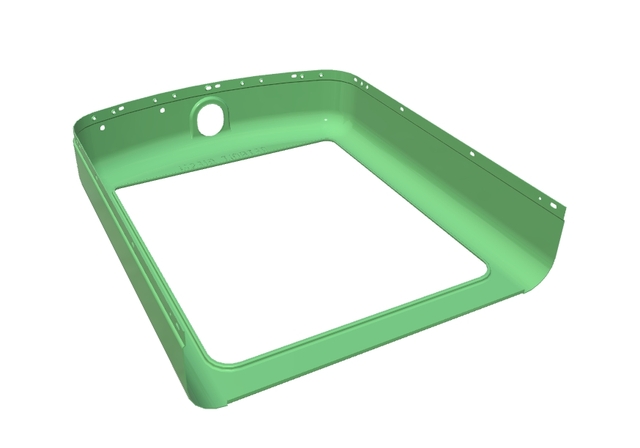

Deep draw stamping involves transforming flat sheet metal into a desired shape by progressively forming it through a series of dies. The technique is a staple in the production of complex, cylindrical, and cup-shaped components which are integral to various applications. One of the key advantages of this method is its efficiency. It reduces material waste and minimizes the need for secondary processes, making it an economically attractive option for large-scale production. At LS Hardware Tech Co., Ltd, precision metal stamping is not just a service; it is a craft honed through meticulous attention to detail and state-of-the-art technology.

The company's factory is equipped with over 100 advanced machining centers, facilitating high production efficiency while maintaining exceptional quality standards. LS is ISO 9001:2015 certified, underscoring their commitment to quality and customer satisfaction. The deep draw tooling employed by LS is designed to accommodate the complex requirements of modern engineering designs. Whether you're dealing with simple shapes or intricate designs, the precision and adaptability of their tooling systems ensure that they can meet a broad spectrum of project requirements.

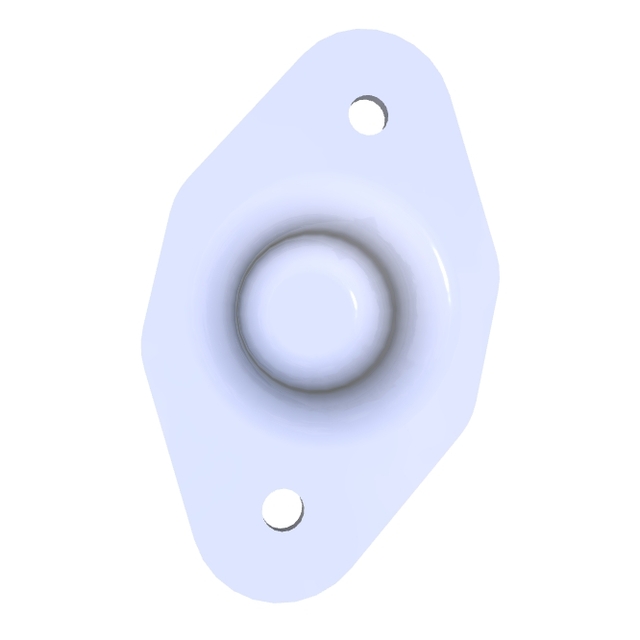

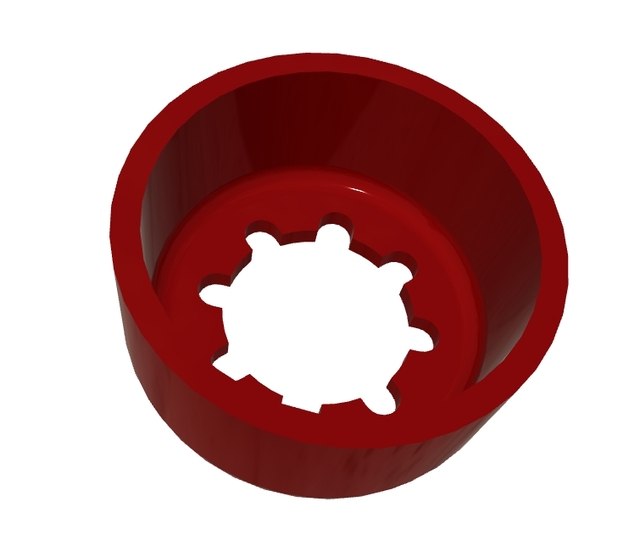

One of the standout products from LS Hardware Tech Co., Ltd is the Multi-Utility Socket Adapter. This innovative solution epitomizes the company's dedication to combining versatility with precision. Designed with functionality in mind, the adapter boasts a durable construction with various cut-outs and holes, making it compatible with a wide range of fastening systems. Its modern, sleek design is a testament to the company's commitment to providing efficient, user-friendly tools that enhance both professional and DIY projects.

In addition to its robust design, the Multi-Utility Socket Adapter is constructed from high-quality materials. This ensures that the adapter not only meets but exceeds customer expectations for reliability and performance. Despite its durability, the product maintains a lightweight profile, emphasizing LS Hardware Tech Co., Ltd’s ability to create products that are both robust and easy to handle. Whether you're a professional craftsman or an enthusiastic DIYer, this socket adapter is engineered to simplify your workload, streamline your projects, and boost productivity.

LS Hardware Tech Co., Ltd’s mission goes beyond merely manufacturing parts; they aim to drive innovation in the industry and provide solutions that empower their clients. Their extensive reach, catering to over 150 countries and regions worldwide, reflects their capability and expertise in the field. As they continue to invest in technology and improve their processes, LS remains committed to delivering innovative manufacturing solutions that meet the evolving needs of their clients, paving the way for new possibilities in the realm of deep draw stamping and beyond.

In conclusion, deep draw stamping is a cornerstone in the manufacturing of stamped metal parts, and companies like LS Hardware Tech Co., Ltd are leading the charge in this pivotal industry. With a focus on quality, innovation, and customer-centric solutions, they uphold the highest standards in manufacturing, ensuring that their products and services consistently meet the demands of their diverse clientele. As technology continues to advance, LS is poised to remain at the forefront, delivering excellence in precision metal stamping for years to come.

Deep Draw Stamping: Techniques & Precision Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Deep Draw Stamping, Hydroforming, Blanking, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Deep Draw Stamping: Elevating Precision and Design

Deep Draw Stamping: Precision and Efficiency Redefined

Exploring Advanced Deep Draw Stamping Techniques for Precision Engineering

Deep Draw Stamping: Precision Solutions by LS Hardware Tech

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Deep Draw Stamping: Precision & Applications

Deep Draw Stamping: Techniques & Precision Solutions

Deep Draw Stamping: Precision Solutions for Modern Industries