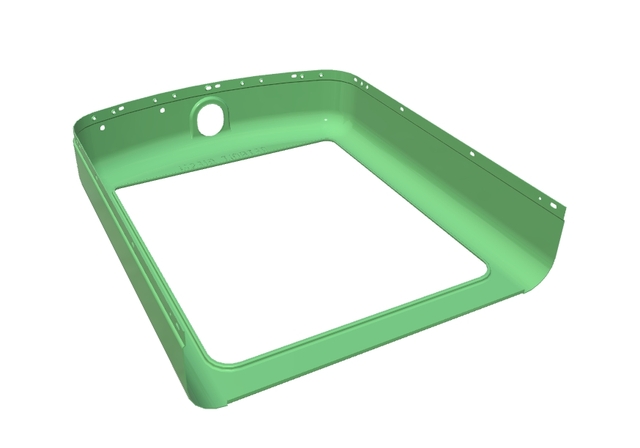

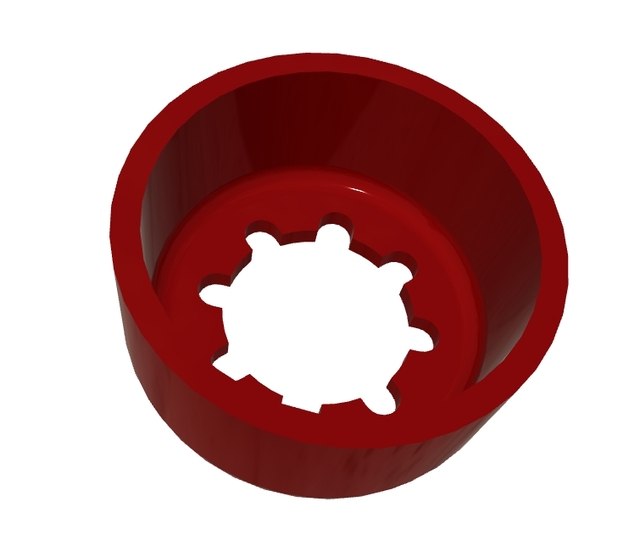

In the fast-evolving world of metal forming technologies, deep draw stamping stands as one of the most versatile and efficient methods. Deep draw stamping is a metalworking process where a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch to create complex shapes. This technique is highly regarded for its ability to produce strong, lightweight, and intricate metal parts, making it a preferred option in various sectors, especially the automotive industry where precision metal forming is critical.

At the forefront of this technology is LS Hardware Tech Co., Ltd, a company renowned for its expertise in manufacturing high-precision hardware and plastic parts. Founded by Mr. Nick Zhang and supported by a team of adept engineers, LS Hardware Tech Co., Ltd has established itself as a leader in delivering top-notch solutions for over two decades. With a foundation rooted in innovation and quality, the company proudly serves more than 5,000 clients across 150 countries, providing products that meet stringent ISO 9001:2015 certification standards.

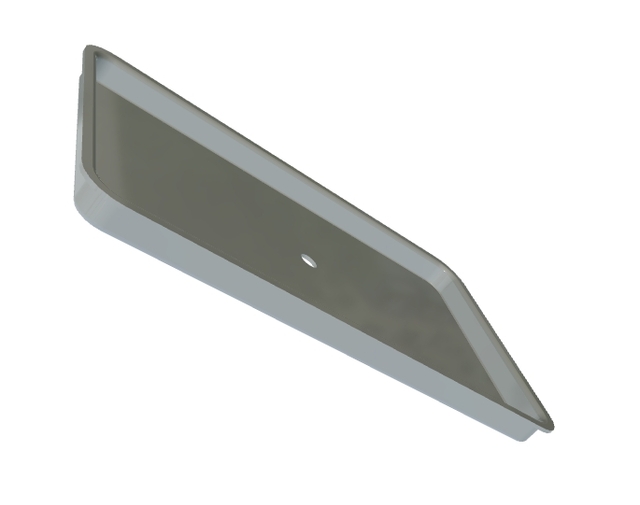

Automotive deep draw stamping is particularly essential in the automotive sector, where custom deep draw parts are integral to vehicle construction. Precision is non-negotiable in this industry; hence, the deep drawing process adopted by LS Hardware ensures that every part meets the exact specifications required for optimal performance. Owing to over 100 high-end machining centers within the company’s facility, LS Hardware Tech Co., Ltd delivers not only efficiency but also unrivaled quality in its products.

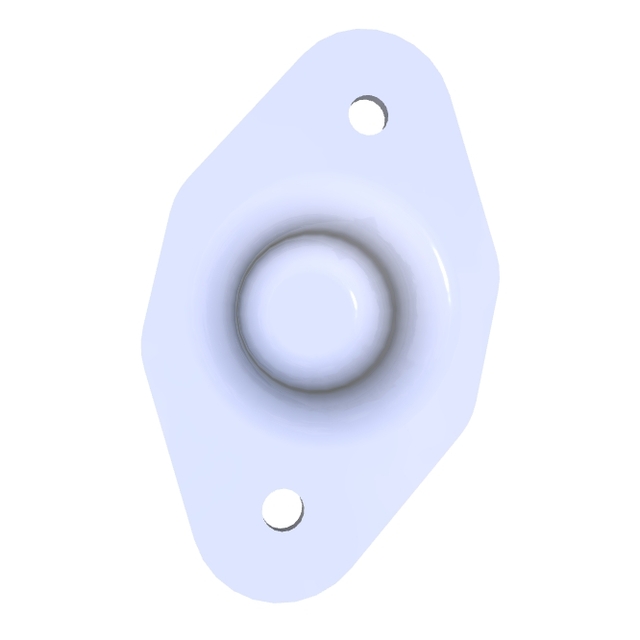

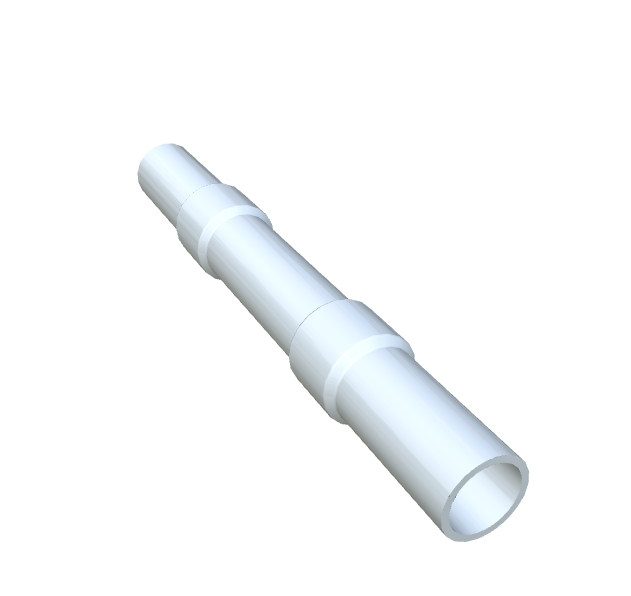

An exciting addition to LS Hardware Tech’s portfolio of high-quality products is the Inline Water Filter Cartridge. Reflecting the company’s commitment to precision and innovation, this water filter promises an efficient filtration experience. With its sleek design and high-quality materials, it seamlessly integrates into any kitchen or bathroom, epitomizing LS Hardware’s dedication to combining functionality with aesthetic appeal. The minimalist, glossy finish of the filter ensures that it blends effortlessly into any decor, offering users a refined and practical solution to water filtration.

Beyond its design, the Inline Water Filter Cartridge exemplifies modern engineering. Featuring a modern connection interface, it allows for easy installation and seamless integration into existing plumbing systems. Designed with the eco-conscious consumer in mind, it removes impurities effectively, providing clean, crisp, and rejuvenating water with every use. This commitment to eco-friendly technology parallels LS Hardware’s goal of delivering sustainable and innovative technology solutions.

As industries continue to evolve, the demand for sophisticated stamping technologies and precision forming methods such as deep draw stamping increases. LS Hardware Tech Co., Ltd continues to meet this demand by improving its processes and capabilities. With expertise spanning across industries such as automotive, medical devices, consumer electronics, aerospace, and industrial equipment, LS Hardware envisions transforming ideas into reality, propelling clients toward the future with cutting-edge manufacturing solutions.

The choice of metals used in deep draw stamping plays a pivotal role in the overall success of precision metal forming processes. LS Hardware Tech places emphasis on utilizing high-quality metals, which ensures that custom deep draw parts are resilient and long-lasting. These materials are carefully selected to adapt to the specific needs of each project, thereby solidifying the company's commitment to excellence and customer satisfaction.

Moving forward, LS Hardware aspires to remain at the forefront of stamping technologies by persistently innovating and pushing the boundaries of what is achievable in the realm of metal stamping. As the company strives to empower its clients with unparalleled products and services, the promise of deeper and more complex stamping solutions illuminates the path toward an advanced future in manufacturing.

In conclusion, deep draw stamping remains an indispensable process in the production of precision metal parts, with applications spanning numerous industries. Companies like LS Hardware Tech Co., Ltd continue to innovate and refine this process, ensuring outstanding product quality and efficiency. By integrating their vast expertise and commitment to technology, they not only deliver custom deep draw parts but also inspire a new standard in manufacturing excellence. The firm’s relentless dedication to customer satisfaction and technological advancement cements its position as a trusted partner to global industries, paving the way for continued success in the ever-expanding world of metal forming technologies.

Deep Draw Stamping: Precision Solutions for Modern Industries

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Deep Draw Stamping, Hydroforming, Blanking, Metal Stamping, Progressive Die Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Deep Draw Stamping: Elevating Precision and Design

Deep Draw Stamping: Precision and Efficiency Redefined

Exploring Advanced Deep Draw Stamping Techniques for Precision Engineering

Deep Draw Stamping: Precision Solutions by LS Hardware Tech

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Deep Draw Stamping: Precision & Applications

Deep Draw Stamping: Techniques & Precision Solutions

Deep Draw Stamping: Precision Solutions for Modern Industries