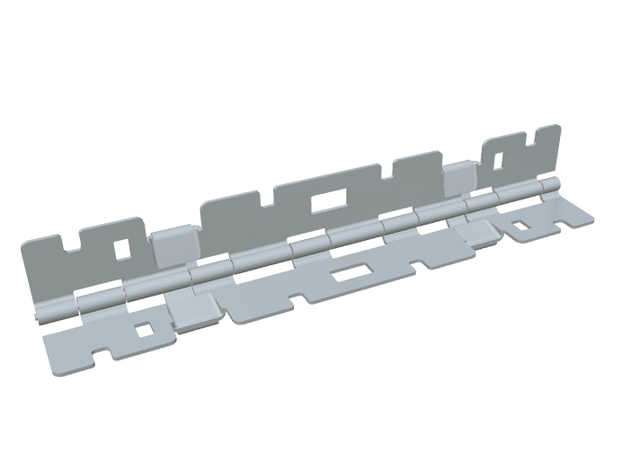

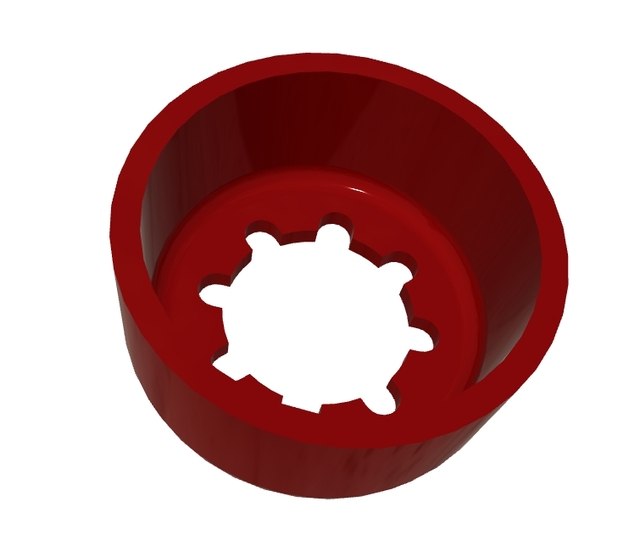

In the cutting-edge world of manufacturing, the blanking process plays a pivotal role in creating precise metal components with remarkable efficiency. This specialized technique involves the removal of material from a metal sheet or coil, yielding perfectly shaped metal blanks for further processing or assembly. With advancements in blanking techniques, the industry has witnessed significant improvements in speed, accuracy, and production capabilities.

At the forefront of these innovations is LS Hardware Tech Co., Ltd. A prominent player in the field, LS has more than two decades of experience in crafting high-quality hardware and plastic parts. Spearheaded by Mr. Nick Zhang and his team of skilled engineers, the company boasts of a powerhouse equipped with over 100 advanced machining centers. This sophisticated setup ensures LS maintains its esteemed reputation for high production efficiency while upholding rigorous standards of quality in its ISO 9001:2015 certified operations.

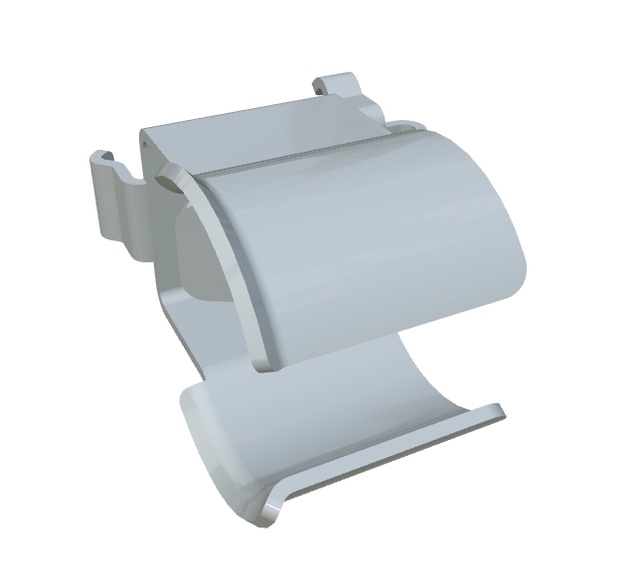

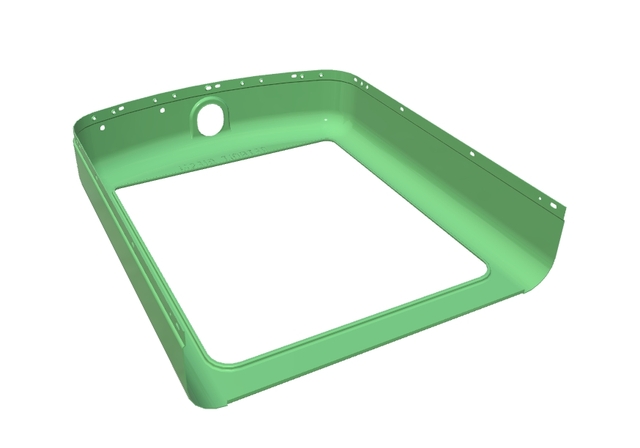

The blanking process forms the backbone of numerous LS projects, including the revolutionary Green Hull Frame. This product exemplifies how cutting-edge engineering and design elegance can converge in both industrial and decorative applications. Engineered with precision, the Green Hull Frame features a seamless and rounded architecture that not only provides superior durability but also enhances aesthetic appeal. Its vibrant green finish serves as more than just a color statement, offering a layer of corrosion resistance that bolsters resilience in various environments.

One cannot overstate the importance of specialized techniques like metal blanking in the production of such advanced components. The strategic use of blanking die ensures that every Green Hull Frame is manufactured to exact specifications, an indispensable feature when dealing with high-precision applications. Moreover, blanking vs punching techniques are often debated in the industry, with blanking favored for its ability to maintain tight tolerances and deliver cleaner cuts, a crucial requirement given the precision demanded in industries served by LS, including automotive, medical devices, and aerospace.

The versatility of sheet metal blanking further underscores its significance in modern manufacturing. By efficiently producing metal blanks, LS can quickly transition from prototype development to mass production, thereby meeting the varied demands of its over 5,000 clientele spread across 150 countries and regions. Whether it's producing intricate parts for consumer electronics or robust components for industrial equipment, the blanking process remains integral to LS's mission of empowering clients to bring their ideas to life.

A distinctive aspect of the Green Hull Frame's design is its series of strategically placed mounting holes, which facilitate versatile attachment in multiple applications. When integrated with other components, these attributes become immensely advantageous, showcasing LS's commitment to delivering practical yet elegantly designed products. Such innovations are not just theoretical; they are a testimony to LS's continuous improvements and dedication to staying ahead in technology and manufacturing solutions.

With automated blanking systems, efficiency is further amplified. By automating this critical step, LS minimizes human error, speeds up production, and ensures consistency across batches. This automation is vital as LS aspires to meet the evolving demands of modern industries while maintaining cost-effectiveness and production timelines.

The company's contribution to the blanking and forming sectors is noteworthy. Through continued research, development, and throughput optimization, LS is not only meeting but exceeding customer expectations. Each Green Hull Frame, built with precision and backed by robust quality assurance processes, reflects LS’s unwavering commitment to innovation, quality, and customer satisfaction.

In conclusion, the blanking process is indispensable in modern manufacturing. LS Hardware Tech Co., Ltd has expertly harnessed this process to deliver exceptional products like the Green Hull Frame, setting new benchmarks in quality and innovation. As industries globally seek more efficient and reliable manufacturing solutions, LS stands as a trusted partner, continually pushing the envelope to meet the ever-evolving needs of its diverse clientele.

Exploring the Blanking Process: Efficiency and Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering the Blanking Process: Precision in Metal Blanking

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process in Metal Fabrication