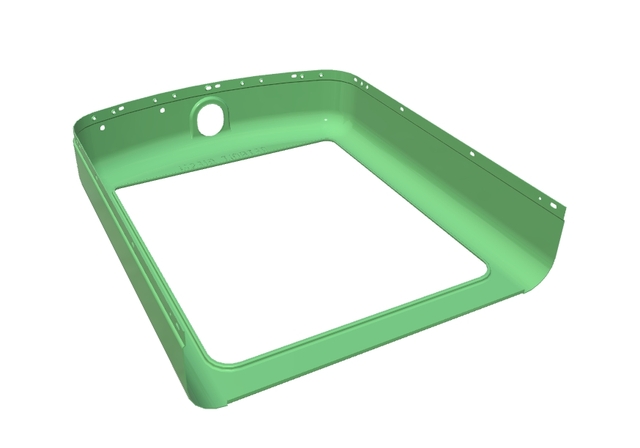

In the world of metal fabrication and manufacturing, the **blanking process** stands out as a crucial procedure for creating high-quality, precise metal components. This process is the introductory step in metal stamping and is pivotal in shaping the final product's performance and durability. The process involves the removal of a specific shape from a larger piece of sheet metal, and with technologies like **blanking tools** and **blanking dies**, this task is accomplished with high precision and efficiency. Commonly used in industries ranging from automotive to consumer electronics and aerospace, blanking plays an indispensable role.

**Sheet metal blanking** is a sophisticated technique that allows the manufacturing of components with complex geometries. This is achieved through state-of-the-art machinery and cutting-edge engineering. The integration of advanced **blanking machines** provides an added level of precision that is necessary for the production of high-precision parts that industries demand. A leading player in this realm is LS Hardware Tech Co., Ltd, a company that has distinguished itself in the manufacturing of hardware and plastic parts.

Founded by Mr. Nick Zhang and a team of experienced engineers, LS Hardware Tech Co., Ltd boasts over 20 years of expertise in the field of manufacturing. The company is known for providing high-efficiency manufacturing solutions and maintains a reputation for quality production strategies. Utilizing over 100 high-end machining centers, LS offers high production efficiency, furthering its capacity to meet the demands of the global market. Adhering to ISO 9001:2015 standards, the company’s reach stretches to more than 150 countries and regions worldwide. With these credentials, the company is positioned to provide solutions that enable the seamless integration of blanking processes in various industries.

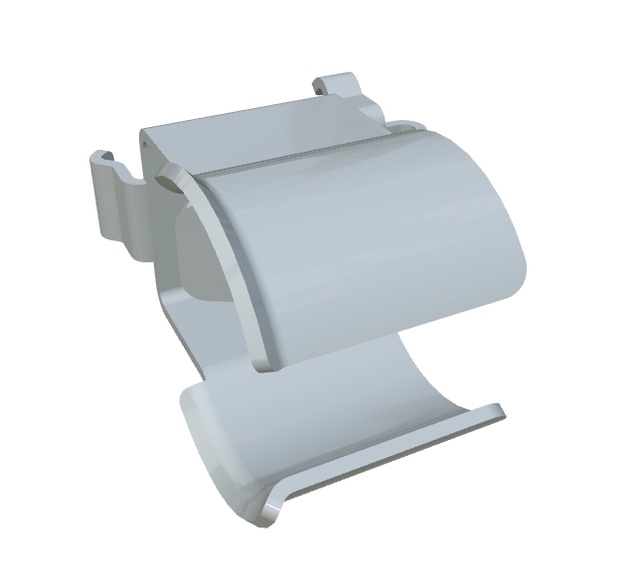

The robustness associated with such processes is epitomized in LS Hardware Tech's product line, such as the newly introduced "U-Hook Clip." The clip serves as an example of how the blanking process can culminate in a product that reflects both aesthetic simplicity and functional utility. Manufactured from high-quality, durable metal, the U-Hook Clip features a minimalist design combined with practical utility. Its precision-crafted U-shape exemplifies the potential of the blanking process, providing a secure grip for organizing cables, hanging lightweight items, or offering a stylish take on a bookmark.

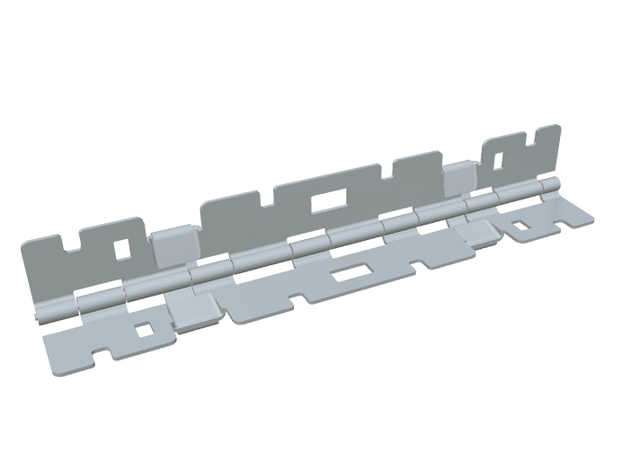

The methodology behind blanking involves using a punch and die to produce parts of specified shapes and sizes, often in high production volumes. *Mechanical blanking* refers to this method where a mechanical press applies a high-force impact to the sheet metal, shearing it into desired shapes. This high-stress environment demands tools capable of enduring wear and tear, which is why **blanking dies** are forged from highly durable materials to withstand the repeated stresses of the blanking operation.

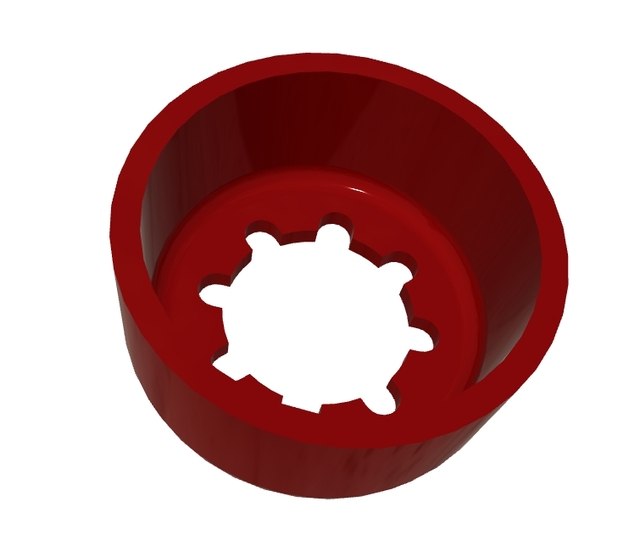

Precision is of paramount importance within the **precision blanking** milieu. This enhanced form of blanking allows for tighter tolerances and finishes that are exceptionally smooth. Industries that demand high accuracy rely on precision blanking to achieve end products that meet stringent quality standards. LS Hardware Tech Co., Ltd operationalizes this through its commitment to delivering innovative manufacturing solutions.

The evolution of blanking processes reflects an increasing demand for efficiency and precision within the metalworking industry. Today, **metal stamping and blanking** are seen as integral steps in transforming raw materials into intricately shaped metal parts that meet specific dimensional requirements. Companies like LS Hardware Tech Co. capitalize on these processes to cater to diverse sector needs, ranging from automotive solutions to tailored components for industrial machinery.

In conclusion, the **blanking process** is a fundamental element across various sectors requiring precise and repeatable metal component manufacturing. LS Hardware Tech's approach, rooted in a commitment to advanced technology and innovative solutions, demonstrates the potential of leveraging blanking to deliver high-quality products such as the versatile U-Hook Clip. As industries continue to evolve, the reliance on precision-engineered solutions like those provided by LS will only increase, reflecting the growing importance of the blanking process in modern manufacturing landscapes.

Understanding the Blanking Process in Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Hydroforming, Blanking, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.