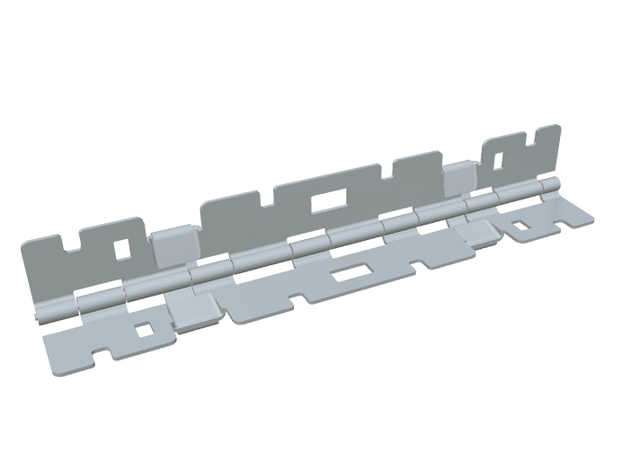

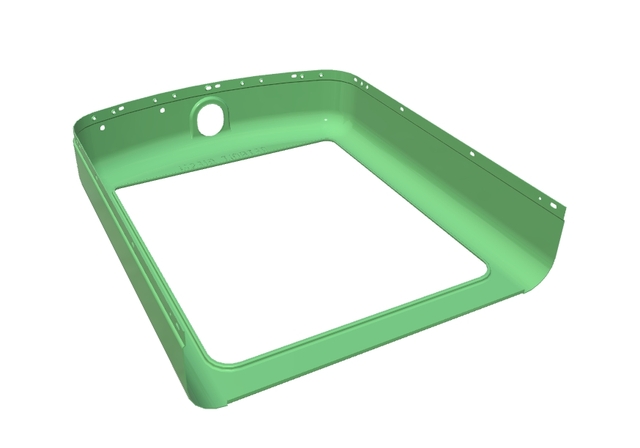

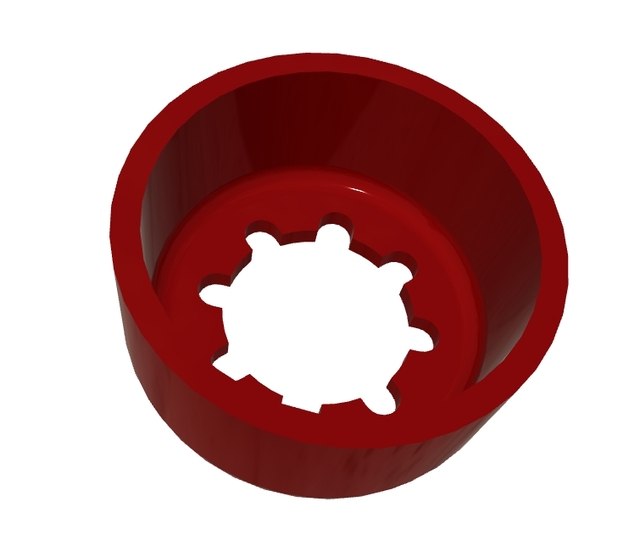

The blanking process is a pivotal operation in the realm of sheet metal fabrication, serving as the first step in transforming raw materials into precise shapes for diverse industrial applications. Utilizing advanced techniques and equipment, the blanking process enables efficient stamping and blanking of metal sheets with speed and accuracy. At the heart of this process lies the blanking die design, which is critical for achieving the desired specifications and encompasses elements such as die material, geometry, and tolerances.

Metal blanking is a versatile procedure used in various industries to manufacture parts ranging from simple washers to complex automotive components. The integration of innovative blanking machines ensures that the output is consistent with high precision and minimal waste. Blanking machines, equipped with sophisticated controls and automation, enhance the efficiency of the blanking operation, making it an indispensable asset for large-scale production.

The sheet metal blanking process has been refined to cater to the needs of various sectors, including automotive, aerospace, and consumer electronics. In these industries, precision and repeatability are paramount, and the material characteristics play a significant role in selecting the appropriate blanking tools and equipment. Blanking tools must be robust enough to handle the demanding conditions of repeated operations, ensuring the longevity and effectiveness of the entire process.

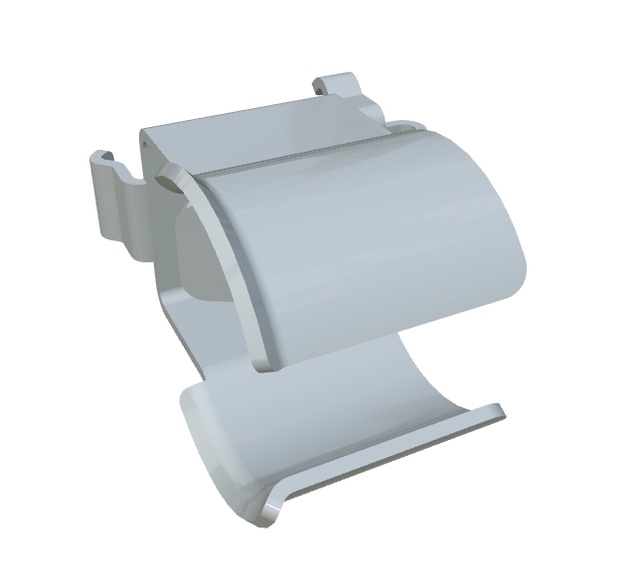

LS Hardware Tech Co., Ltd stands out in the competitive landscape of hardware and plastic part manufacturing. Founded by Nick Zhang and his proficient team of engineers, LS has been at the forefront of delivering innovative solutions for more than two decades. This expertise is manifested in products like the sleek and innovative wall mount bracket, designed not only for functionality but also for the modern aesthetic appeal.

This unparalleled wall mount bracket is crafted from high-quality, durable glossy material, marrying durability with a striking finish that complements any contemporary space. Its curved design serves dual purposes: seamlessly integrating with various devices or components and ensuring both stability and style. The minimalistic profile of the mount allows for a clutter-free environment, making it an ideal fixture for enhancing the organization and aesthetic of living or workspaces.

The robust construction of the wall mount bracket guarantees lasting support, a critical aspect for safely securing devices. A straightforward installation process underscores its accessibility, aligning with LS Hardware Tech Co., Ltd’s mission to empower customers with innovative solutions that are easy to implement. This customer-centric approach is reflected in the company’s ability to continually improve processes and capabilities, ensuring that they remain at the forefront of technology.

The success of LS Hardware Tech Co., Ltd can be attributed to the high production efficiency achieved through its well-equipped factory, boasting over 100 high-end machining centers. This state-of-the-art facility underpins the company’s ability to churn out top-notch products, meeting the diverse needs of more than 5,000 clients worldwide. LS’s commitment to quality is further validated by its ISO 9001:2015 certification, establishing it as a trusted partner to major factories in China and beyond.

Particularly in the domain of high-precision parts manufacturing, LS Hardware Tech Co., Ltd meets the full range of needs from prototypes to mass production. This capability is crucial in sectors such as automotive, medical devices, and aerospace, where precision and reliability are non-negotiable. By leveraging its extensive experience and advanced technology, LS continues to deliver solutions that drive innovation and empower clients to bring their ideas to life.

In conclusion, the blanking process is a cornerstone of metal fabrication, facilitating the creation of intricate shapes and components that feed into countless applications across various industries. Paired with the expertise of companies like LS Hardware Tech Co., Ltd, which provides cutting-edge solutions in hardware and plastic part manufacturing, the potential to achieve efficient, precise, and high-quality outcomes is boundless. As the demand for advanced manufacturing solutions grows, LS Tech remains committed to pushing the boundaries of what is possible, ensuring consistent delivery of top-tier products to its clients worldwide.

Blanking Process: Mastering Metal Blanking and Tool Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering the Blanking Process: Precision in Metal Blanking

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process in Metal Fabrication