Laser cutting technology has revolutionized the way we approach manufacturing and production processes. As the main_keyword of many modern industrial operations, laser cutting technology offers precision, speed, and versatility in multiple applications. This innovative technology has become a cornerstone of industries such as manufacturing, automotive, aerospace, and even art installations. With its ability to deliver laser cutting services tailored to specific needs, it ensures a high level of accuracy and efficiency, making it a sought-after approach for custom laser cutting projects.

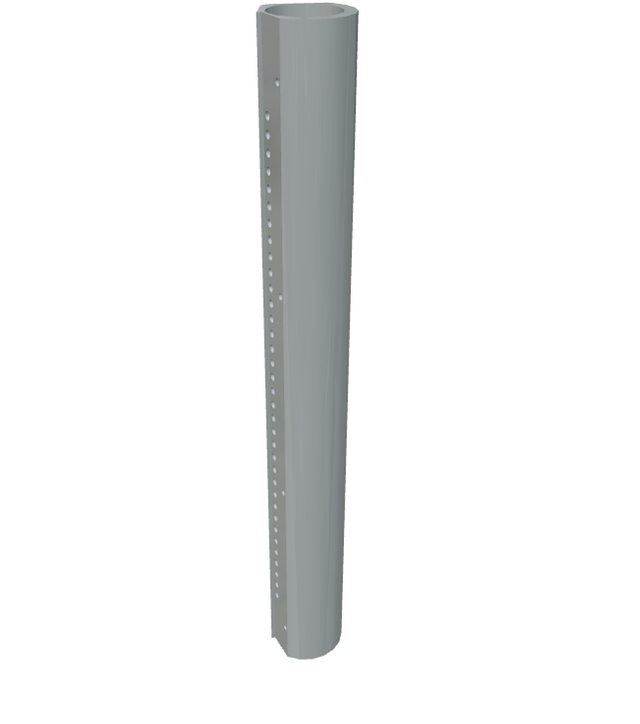

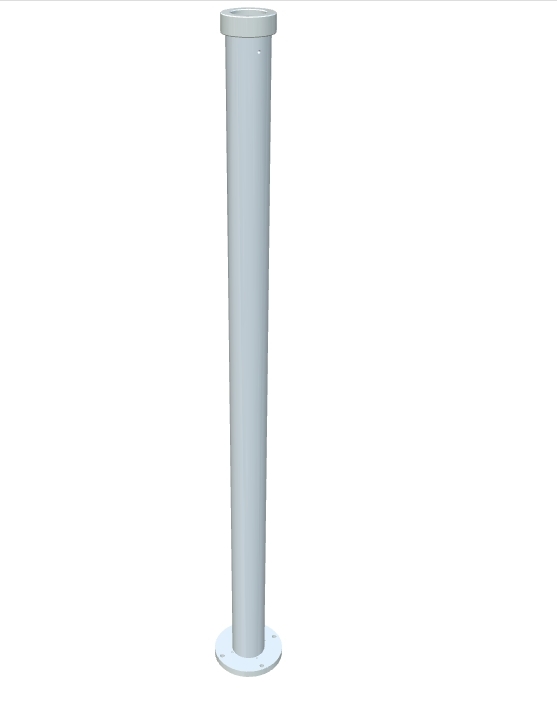

The significance of laser cutting technology lies in its ability to cut through a wide range of materials with unparalleled precision. From metal laser cutting, which is crucial for automotive and aerospace industries, to acrylic laser cutting and wood laser cutting used in creative and decorative projects, the versatility of this technology cannot be overstated. The precision laser cutting capabilities allow for creating intricate designs with clean edges and smooth finishes, suitable for both industrial and artistic applications.

The concept of a laser cutting machine revolutionizes the way raw materials are transformed into finished products. These machines harness powerful laser beams to carefully slice through materials with high precision and little wastage, resulting in optimized production processes. The market has seen significant advancements in laser cutting machines, making them more accessible and efficient for businesses of all sizes, offering a wider range of laser cutting services to meet diverse needs.

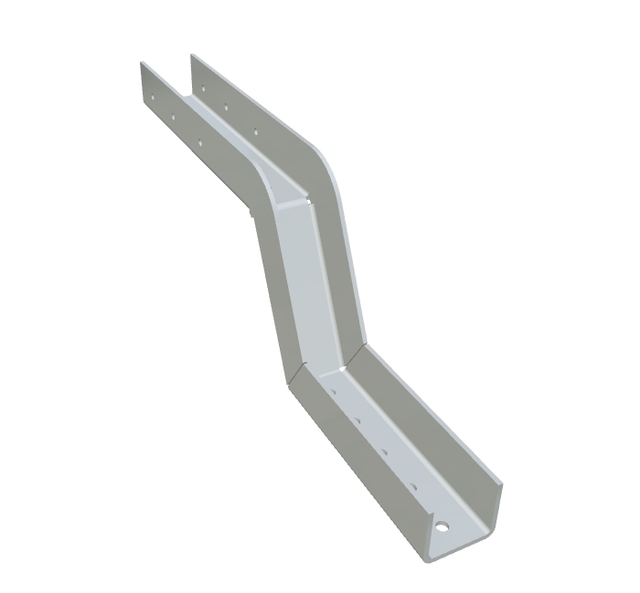

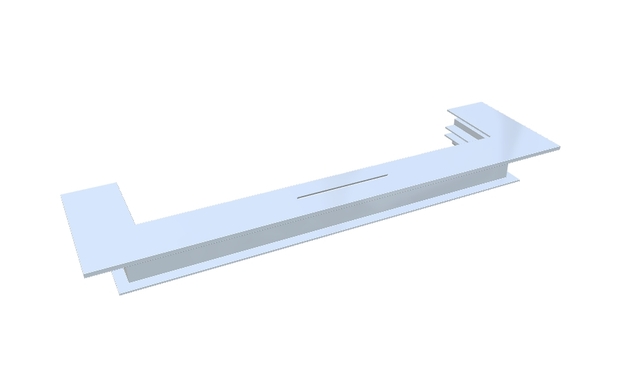

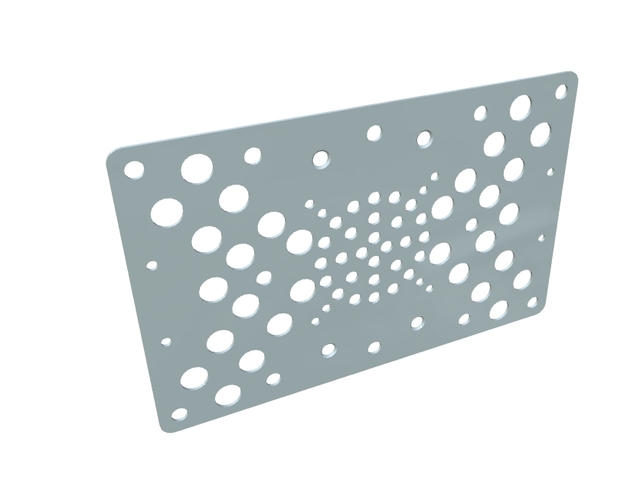

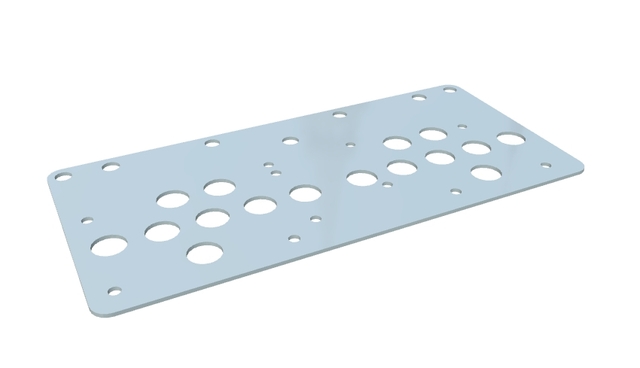

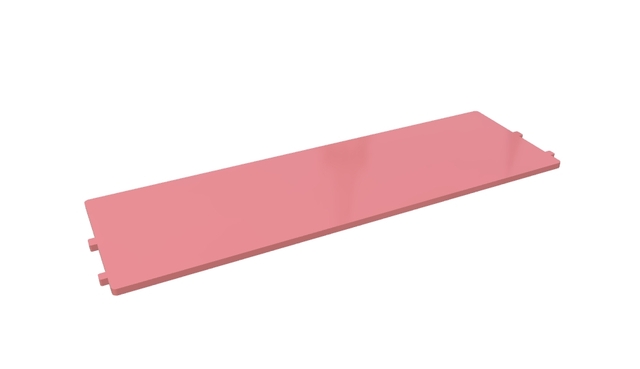

A prime example of laser cutting technology at work is in the development of high-quality architectural components such as the sleek and innovative architectural bracket. These brackets are not only a testament to superior craftsmanship but also epitomize form meeting function through precision engineering and design simplicity. Crafted from high-grade materials, these brackets offer maximum strength and durability without sacrificing aesthetic appeal. With clean lines and geometric elegance, they seamlessly integrate into various architectural projects.

The architectural bracket's minimalist design, complemented by a subtle slotting feature, enhances both aesthetic appeal and functionality. This allows for easy installation while maintaining a refined look. Its versatility makes it ideal for supporting beams, shelves, and other horizontal surfaces, providing style and stability. Such innovations demonstrate how laser cutting technology is not limited to industrial use but can extend to creating elegant, practical solutions for everyday applications.

As industries continue to look for precision, efficiency, and eco-friendly practices, the adoption of laser cutting technology is expected to increase. Businesses can now achieve intricate designs and precise cuts that were once thought impossible, opening new avenues for innovation and creativity. Whether it’s for producing architectural marvels or everyday items, the demand for laser cutting services that offer precision and customization continues to grow.

In conclusion, laser cutting technology remains at the forefront of modern manufacturing and design. Its ability to cut through diverse materials with precision has enhanced its application across various sectors, from industrial to artistic. The development of products like the architectural bracket further showcases the practicality and elegance that laser cutting technology can offer. With continuous advancements, laser technology will likely redefine the boundaries of what's possible in design and manufacturing, ensuring that products are not only functional but also aesthetically pleasing. This integration of technology, design, and functionality keeps laser cutting at the core of innovation, paving the way for a new era of design and manufacturing excellence. Its application across different materials and the ability to offer customized solutions makes it an indispensable tool for today’s industries.

Revolutionizing Industries with Laser Cutting Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Enhance Construction with Laser Cutting Services

Revolutionizing Industries with Laser Cutting Technology

Unleashing Precision: The Rise of Laser Cutting Services

Revolutionize Your Design with Laser Cutting Services

Laser Cutting Services: Innovating Precision & Versatility

Revolutionizing Manufacturing with Laser Cutting Services

Revolutionizing Precision: Laser Cutting Services Unveiled

Revolutionize Manufacturing with Laser Cutting Services