In the ever-evolving world of manufacturing and design, **laser cutting services** have emerged as a game-changer, providing precision, efficiency, and versatility like never before. This cutting-edge technology is reshaping industries by enabling intricate designs and seamless fabrication. With the ability to cut through various materials with unparalleled accuracy, laser cutting is becoming an indispensable tool for businesses that require high-quality finishes and rapid production. As we delve into the realm of laser cutting technology, we discover its immense potential and applications across multiple sectors.

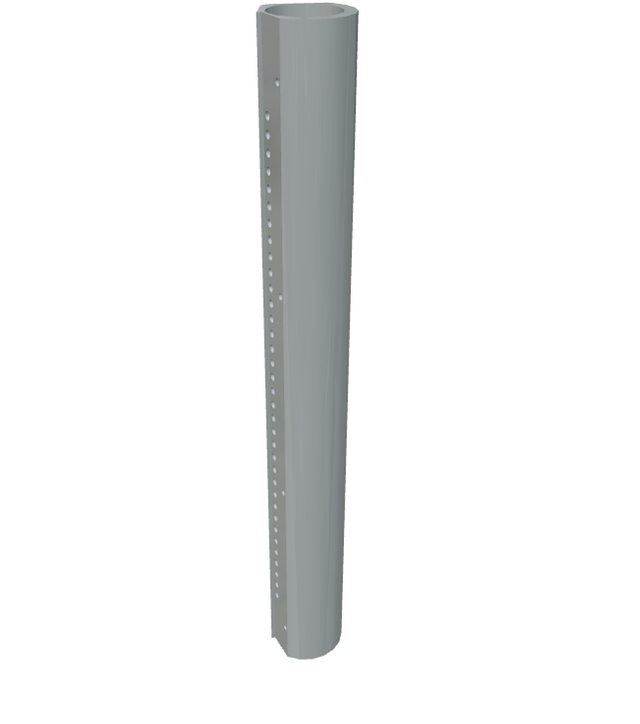

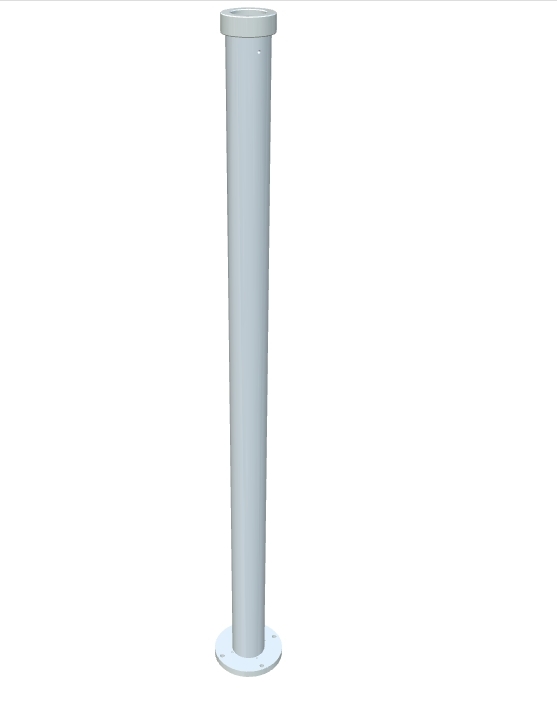

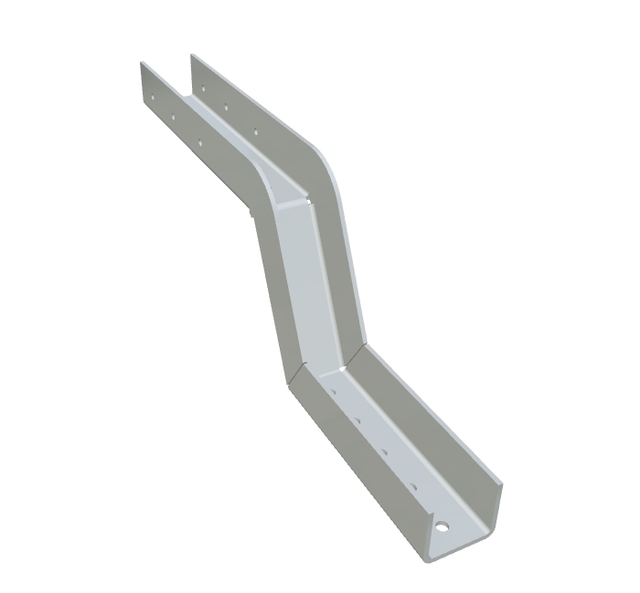

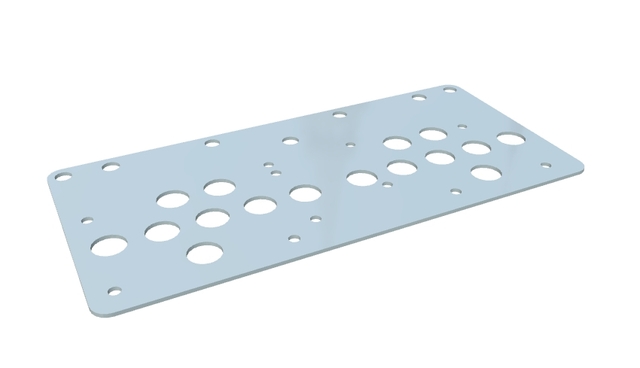

Laser cutting technology has revolutionized the way industries approach manufacturing. By utilizing high-powered laser beams, laser cutting machines precisely slice through materials, achieving intricate designs and shapes that would be challenging with traditional methods. The accuracy and speed of industrial laser cutting make it ideal for applications ranging from aerospace and automotive to fashion and interior design. The technology’s ability to handle diverse laser cutting materials, including metals, plastics, wood, and composites, provides an edge that conventional cutting tools simply cannot match. This versatility is what sets laser cutting apart as a preferred method for businesses seeking precision and detail in their products.

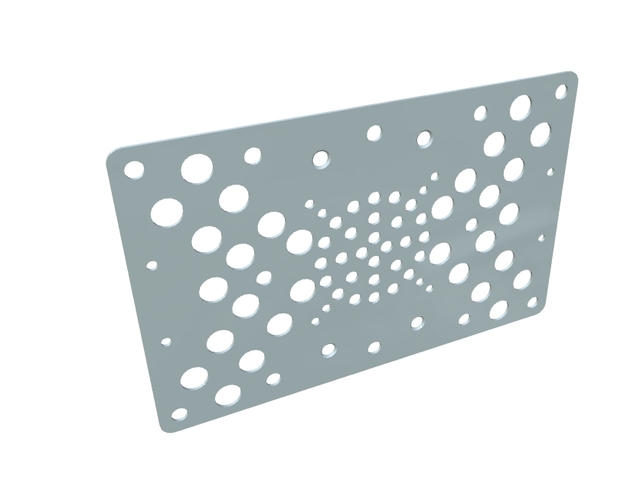

One of the standout applications of laser cutting services is in metal laser cutting. As industries like automotive and aerospace demand higher accuracy and efficiency, laser cutting steps up to the challenge, offering unparalleled detail in metalwork. Whether it is creating complex components for machinery or aesthetically pleasing metal artwork, the capabilities of laser cutting machines are unmatched. The seamless edges, smooth finishes, and reduced material wastage make laser cutting a cost-effective option for manufacturers focusing on quality and sustainability.

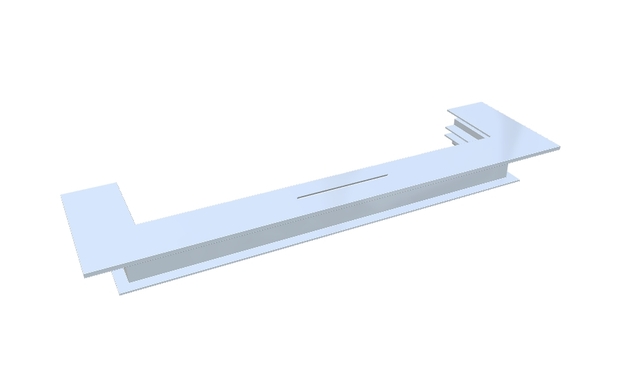

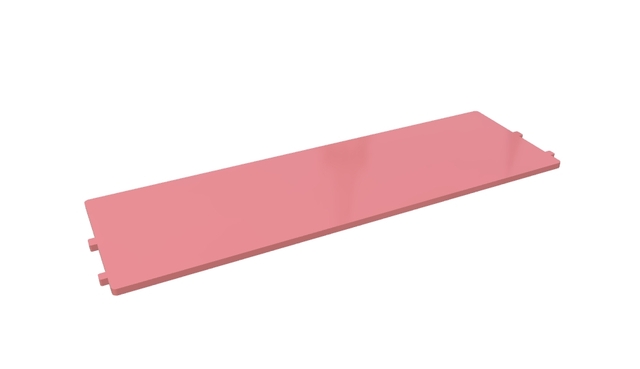

Aside from industrial applications, custom laser cutting is thriving, allowing for unique and personalized designs. In interior design, for instance, laser cutting provides architects and designers with endless possibilities to create stunning and intricately detailed pieces. From modular panels to bespoke furniture, the fusion of creativity and technology results in products that not only look exceptional but are functional and durable. The modular panel, with its chic pink finish, is a prime example of how laser cutting can be utilized to create contemporary designs that enhance both style and practicality. The seamless connections facilitated by laser technology allow for easy installation and rearrangement, catering to both residential and commercial needs.

Beyond its practical applications, laser cutting services have significant eco-friendly advantages. The precision of laser cutting reduces material waste, a crucial factor in fostering sustainable manufacturing practices. Industries adopting laser technology are not only benefiting from reduced costs but also contributing to environmental conservation. By minimizing waste and optimizing material usage, laser cutting aligns with global trends toward eco-conscious production.

In conclusion, laser cutting services stand at the forefront of innovation, offering industries a tool that elevates manufacturing capabilities to new heights. With applications that range from industrial to artistic, this technology continues to transform possibilities into reality. The sleek modular panel with a chic pink finish exemplifies the future of design—blending style, functionality, and technology. As more businesses recognize the value of laser cutting, we anticipate even greater advancements, shaping a future where precision and creativity know no bounds.

Revolutionize Manufacturing with Laser Cutting Services

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.