In today's rapidly advancing industrial landscape, sheet metal fabrication services stand as a cornerstone technology pivotal to a multitude of sectors, including automotive, aerospace, medical devices, and consumer electronics. As industries strive for innovation and efficiency, services like custom sheet metal fabrication and CNC sheet metal fabrication emerge as indispensable tools in crafting components that meet exacting specifications and complex design requirements.

LS Hardware Tech Co., Ltd, under the adept leadership of Mr. Nick Zhang and his team of seasoned engineers, has become a beacon of excellence in the realm of hardware and plastic parts manufacturing. With over 20 years of experience, their expertise is not just in delivering high-quality sheet metal parts but also in adapting to the ever-evolving industrial demands. Using advanced metal fabrication techniques, LS Hardware Tech Co., Ltd has served more than 5,000 clients globally, carving a niche in high-precision manufacturing solutions.

The company's state-of-the-art facilities, equipped with over 100 high-end machining centers, ensure an unparalleled production efficiency that meets international standards of quality and reliability. Their ISO 9001:2015 certification is a testament to their commitment to maintaining top-notch production practices. As a trusted ally to major factories across China, LS provides comprehensive manufacturing solutions, from initial prototypes to full-scale production, offering sheet metal cutting services and employing advanced sheet metal bending techniques to cater to a broad array of industrial needs.

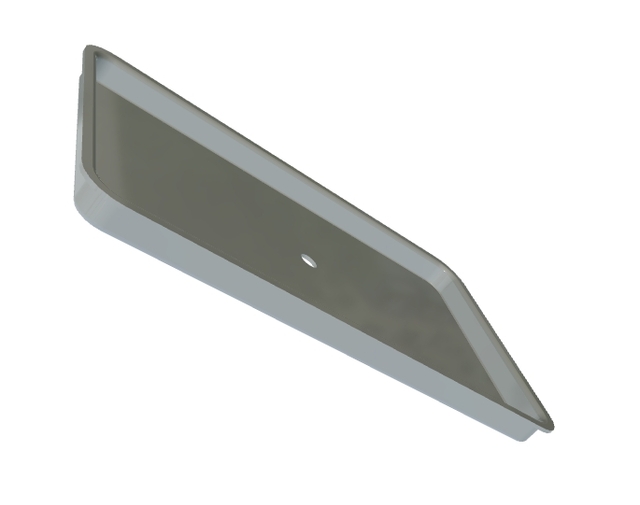

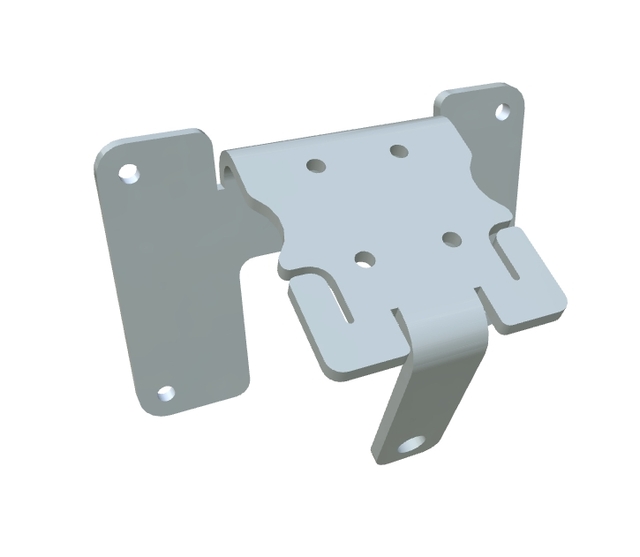

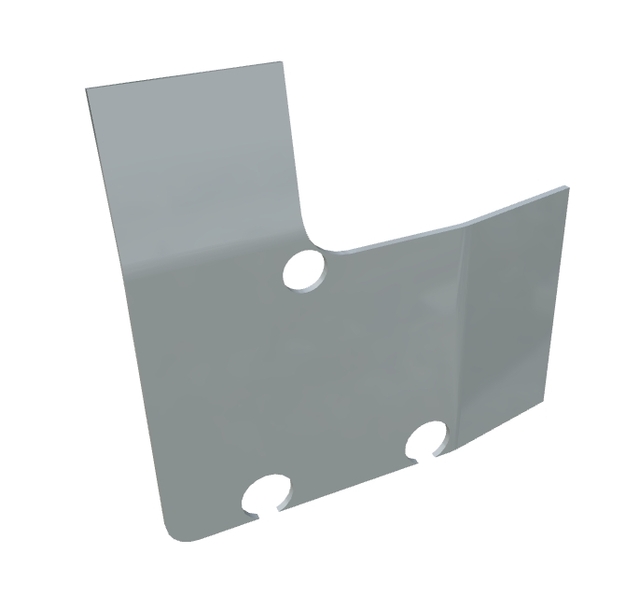

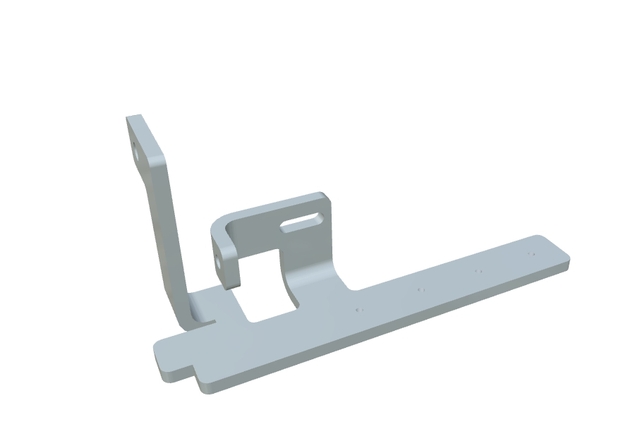

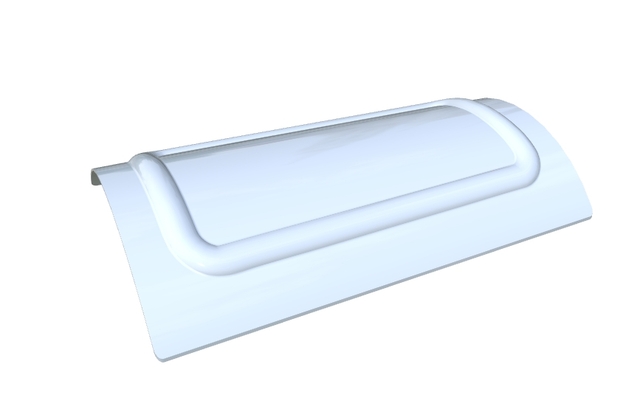

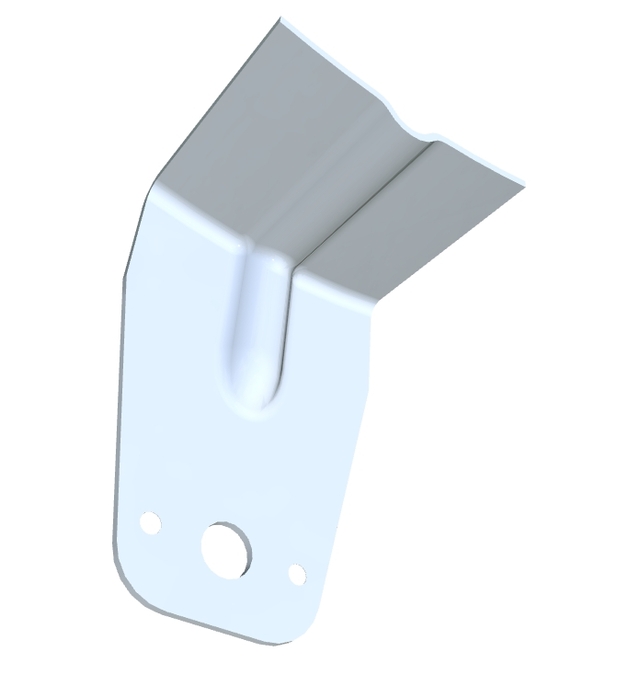

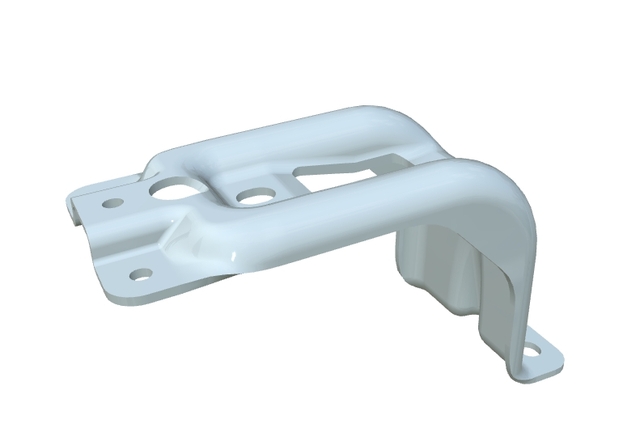

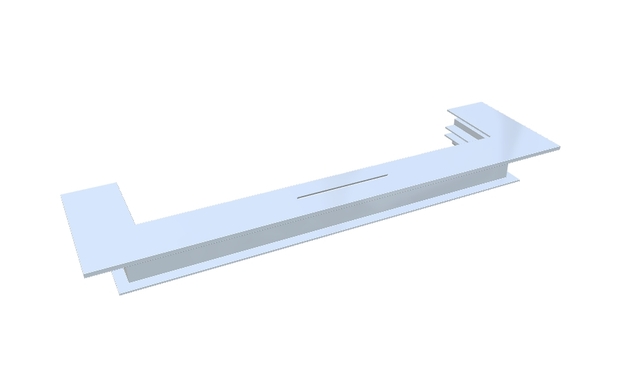

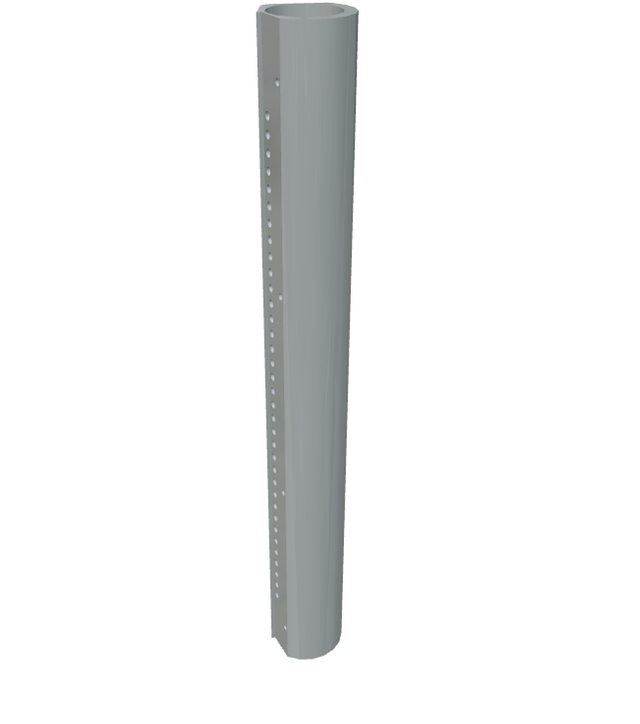

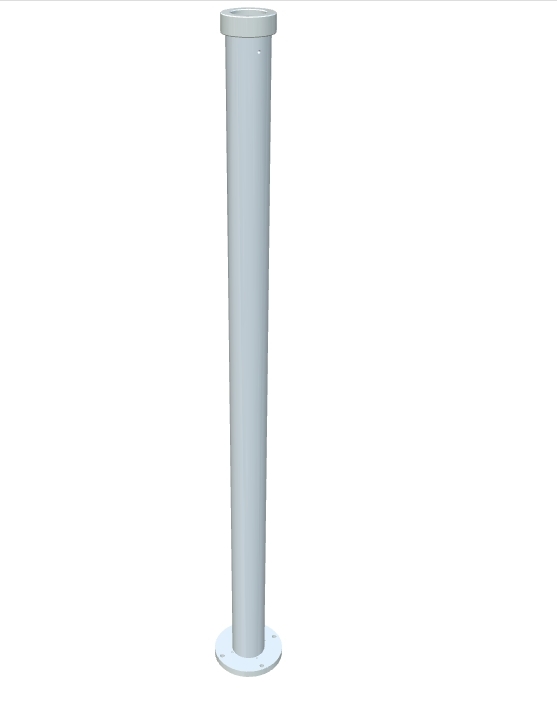

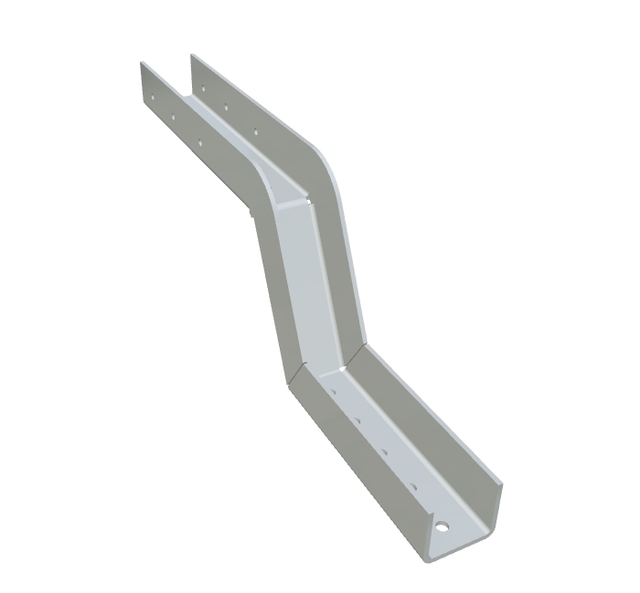

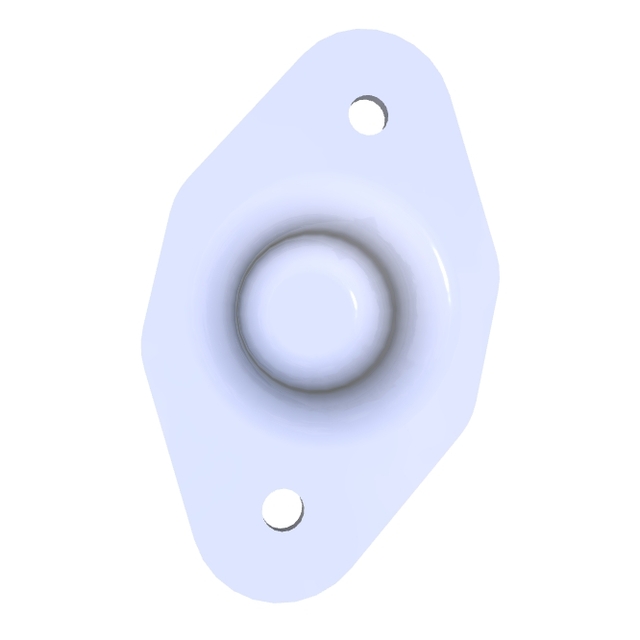

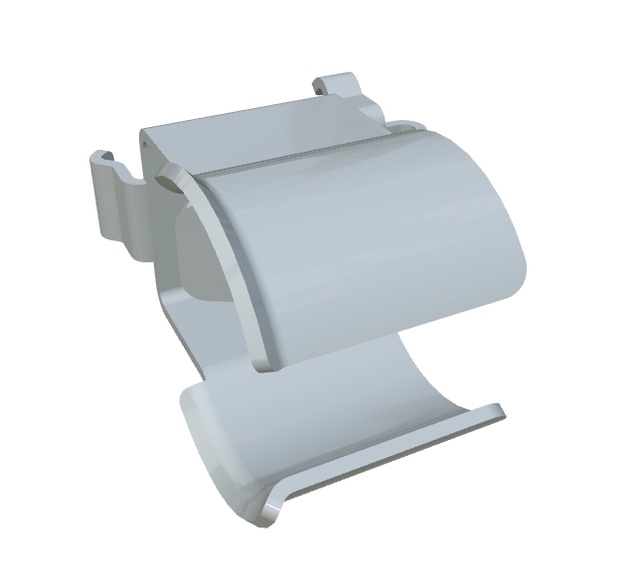

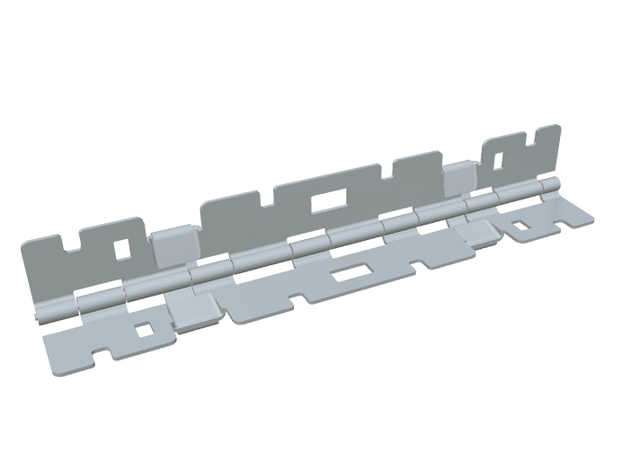

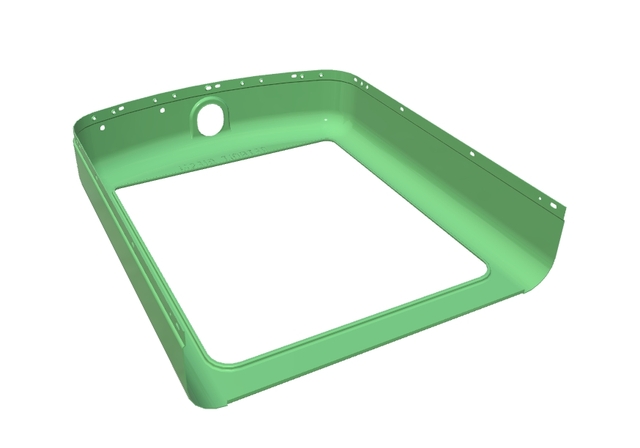

A shining example of their innovative prowess is the sleek Wall Mount Bracket, a custom sheet metal fabrication product designed with precision and aesthetic flair. Crafted from high-grade, durable metal, this indispensable accessory ensures safe and secure installation of flat-screen televisions or monitors. With its robust construction, complemented by a seamless matte finish, the Wall Mount Bracket not only guarantees durability and resistance to wear and corrosion but also epitomizes modern industrial design.

The Wall Mount Bracket is tailored with pre-drilled holes, ideal for ease of attachment while aligning impeccably with standard VESA mount configurations, making it compatible with a wide array of device sizes. This innovative product blends functionality with style, providing an uncluttered, streamlined look perfect for professional environments and home theaters alike.

Moreover, LS Hardware Tech’s mastery in sheet metal welding processes further underscores their ability to deliver precision-engineered products that embody both robustness and elegance. Their Wall Mount Bracket is a testament to the seamless integration of cutting-edge manufacturing processes and customer-centric design, ensuring that every product not only meets but exceeds expectations.

In the competitive sphere of industrial sheet metal fabrication, LS Hardware Tech's unwavering dedication to innovation equips them to meet and surpass the dynamic needs of their clientele. The company's continual investment in technology and their adept use of CNC sheet metal fabrication techniques highlight their resolve to push the boundaries of what is possible, delivering products that transform clients' concepts into tangible realities.

As industries continue to grow and adapt to new challenges, the importance of reliable and versatile sheet metal fabrication services can hardly be overstated. LS Hardware Tech remains committed to leading the charge, with a mission grounded in empowering their clients through innovative solutions that drive success. With a footprint in over 150 countries and regions worldwide, their influence and contribution to global manufacturing practices continue to expand, setting new benchmarks within the industry.

In conclusion, sheet metal fabrication services serve as a crucial component in the production landscape, fostering innovation and quality in product design and manufacturing. LS Hardware Tech Co., Ltd exemplifies these ideals, providing clients with the expertise and resources necessary to actualize their projects with precision, efficiency, and aesthetic excellence. Their dedication to advancing manufacturing capabilities ensures that they remain at the forefront of the industry's future, ready to tackle any challenge with cutting-edge solutions.

Revolutionizing Industries with Sheet Metal Fabrication Services

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Laser Cutting, Bending, Stamping, Welding, Sheet Metal Fabrication |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering the Blanking Process: Precision in Metal Blanking

Exploring the Hydroforming Process: Advantages & Applications

Mastering Stamping Techniques in Modern Manufacturing

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process in Metal Fabrication