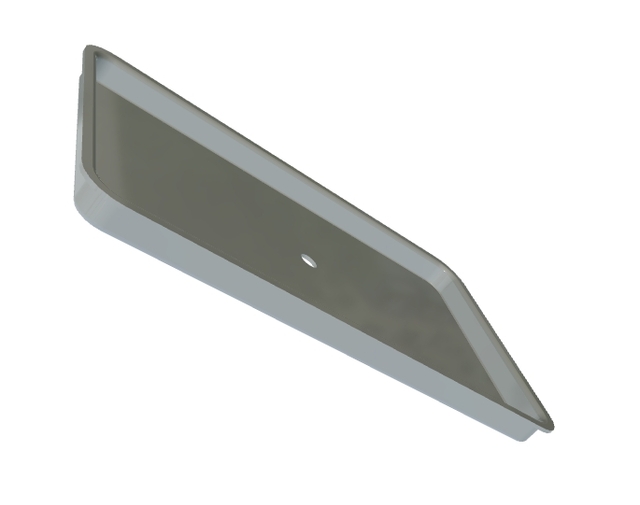

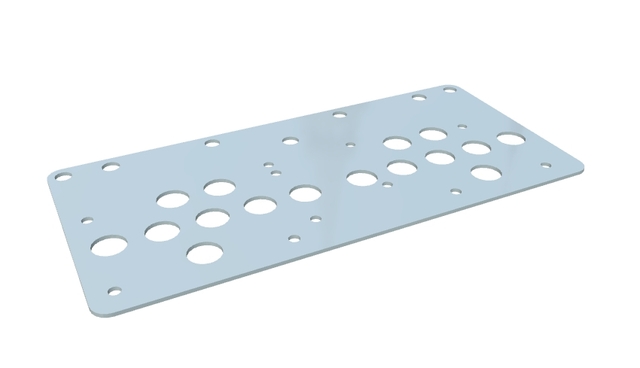

What Makes This CNC-Machined Metal Panel Ideal for Industrial Applications?

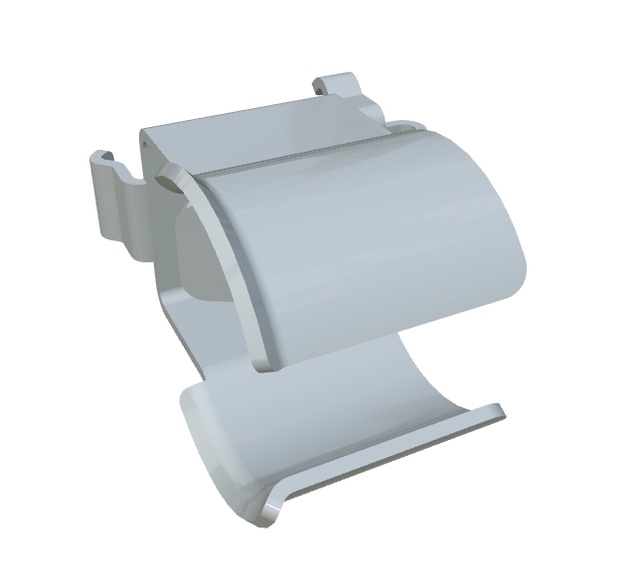

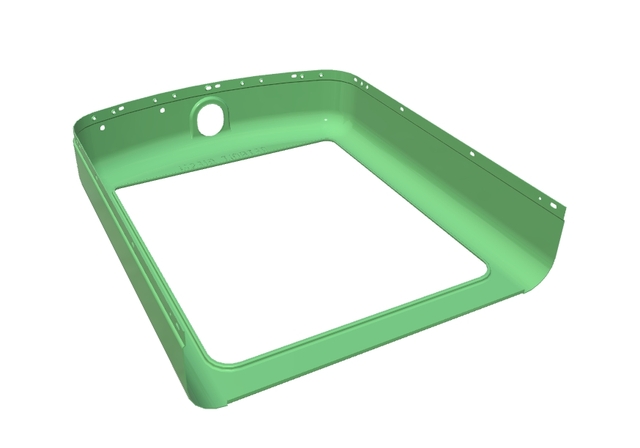

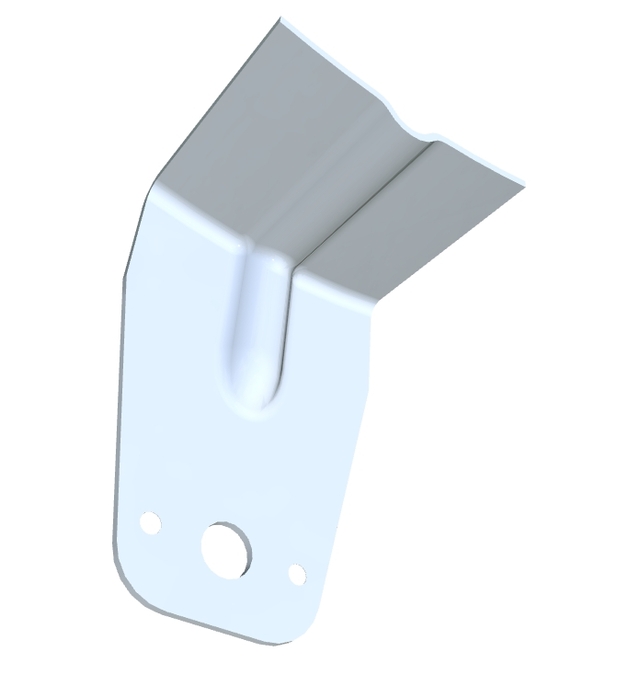

This precision-engineered CNC-machined metal panel is crafted for robust performance in high-demand industrial applications. With a focus on durability and customizability, it is a versatile component suitable for various industries.

Key Features of the Metal Panel

High Structural Integrity

The panel boasts excellent strength-to-weight ratio, making it suitable for applications requiring durability and stability under pressure. Its unique design reinforces load-bearing capacity.Custom Design Options

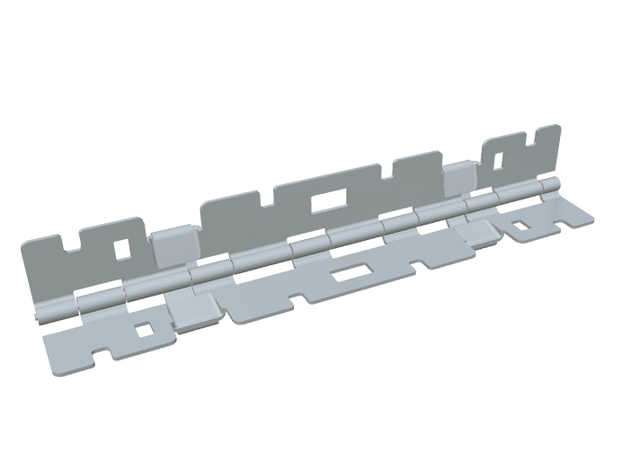

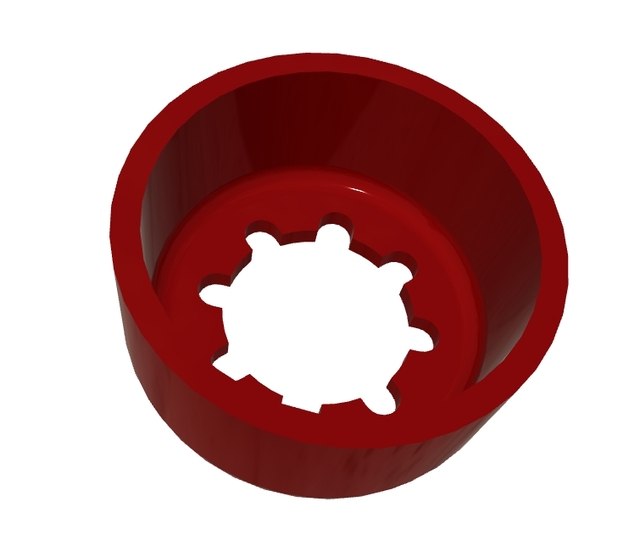

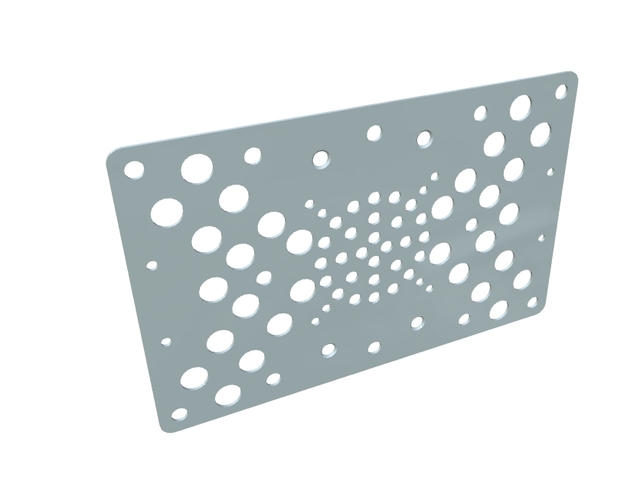

Tailored to specific project needs, this panel can be customized with holes, slots, and unique geometric patterns to fit industrial machinery or equipment perfectly.Surface Treatment Choices

The metal panel is available with various finishing options, such as anodizing, powder coating, or polishing, to enhance corrosion resistance and aesthetics. Explore our surface finishing services.Precision Manufacturing

Using advanced CNC techniques, this part achieves tight tolerances, ensuring perfect fit and seamless integration in complex assemblies.

Applications Across Industries

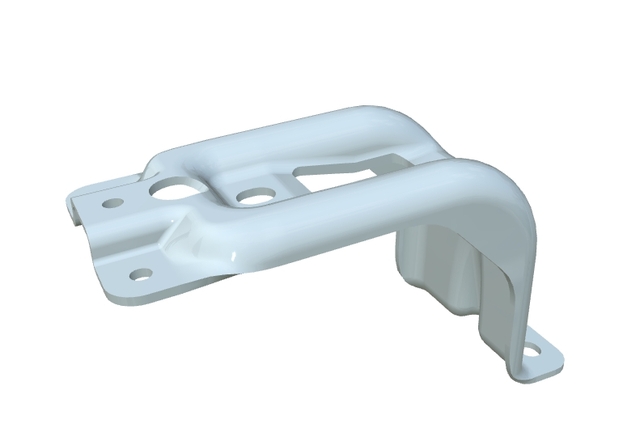

Industrial Equipment

Widely used in machinery and equipment, this panel supports operations requiring high precision and strength. Learn more about industrial applications.Automotive

Ideal for automotive structural components, such as body panels or reinforcements. Its lightweight nature reduces overall vehicle weight without compromising strength. Explore automotive solutions.Aerospace

Precision panels like this are used in aviation to ensure stability and durability in high-pressure conditions. Check out aerospace CNC machining.Consumer Electronics

Serves as a reliable base for enclosures, protecting sensitive electronic components in harsh conditions. Visit consumer electronics applications.

Material Options for Manufacturing

Aluminum

Lightweight, corrosion-resistant, and perfect for aerospace and automotive applications.Stainless Steel

Offers superior strength and wear resistance, suitable for heavy-duty industrial use.Titanium

Known for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace projects.Cold-Rolled Steel

Provides exceptional durability for applications requiring rugged performance in harsh environments.

The Manufacturing Process

Material Selection

High-grade materials are chosen to meet application-specific needs, ensuring reliability and longevity.CNC Machining

Advanced 5-axis CNC milling and turning processes are employed for precision cutting and shaping of the panel. Learn about CNC milling services.Surface Finishing

Options like anodizing, bead blasting, or powder coating are applied for enhanced durability and appearance. Explore surface finishing.Quality Assurance

Each panel undergoes rigorous inspections to ensure it meets strict industry standards.

Why Choose Us for CNC Machining?

Custom CNC Solutions

We offer tailored parts, including unique panel designs, to meet your requirements. Discover custom CNC machining.Fast Turnaround Time

Get your components delivered quickly without compromising quality. Request a quote today.Industry Expertise

Serving multiple sectors, from aerospace to robotics, we deliver precision and reliability. Explore industry solutions.Proven Quality

Our focus on quality assurance ensures every component meets stringent standards, from prototyping to full production runs.