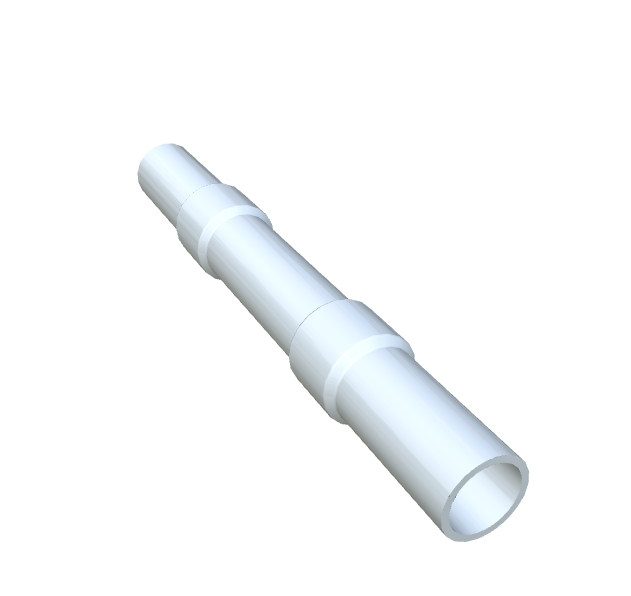

In the realm of modern manufacturing, the hydroforming process stands out as a revolutionary technology that has transformed the way intricate metal components are designed and produced. At its core, hydroforming technology involves utilizing high-pressure hydraulic fluid to shape a workpiece into a desired form. This process offers numerous advantages over traditional stamping methods, making it a preferred choice across various industries.

One of the primary benefits of the hydroforming process is its ability to create complex shapes with a single operation. This reduces the need for secondary processes and multiple parts, leading to significant cost savings and improved efficiency in production. Hydroforming applications are vast, with industries such as automotive, aerospace, and consumer electronics leveraging its capabilities to produce lightweight yet strong components. The automotive sector, in particular, relies heavily on hydroforming machinery to manufacture parts such as body panels and engine components, achieving precise tolerances and superior surface finish.

The LS Hardware Tech Co., Ltd, founded by Mr. Nick Zhang and a team of seasoned engineers, is a prominent player in the manufacturing sector, known for pushing the boundaries of innovation. With over 20 years of experience in making hardware and plastic parts, LS has become synonymous with high production efficiency and top-notch product quality. The company's expertise and cutting-edge hydroforming equipment suppliers enable them to deliver high-precision parts tailored to the specific needs of various industries, from automotive to aerospace.

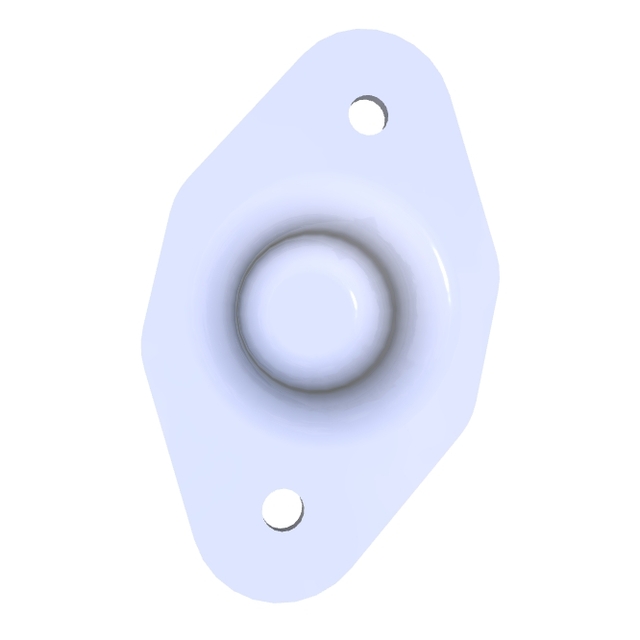

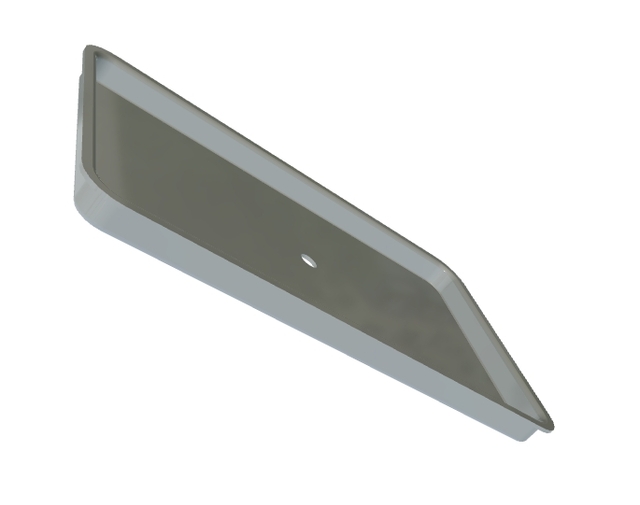

LS's Reflective Angle Bracket exemplifies the application of advanced manufacturing techniques. This minimalist bracket, instrumental in interior and architectural designs, is crafted using durable materials through precise processes like hydroforming. Its unique reflective surface and angular design make it an aesthetic masterpiece, effortlessly integrating into modern interiors. With easy installation facilitated by pre-drilled holes, the bracket is a practical solution for residential and commercial environments alike.

The continuous evolution of hydroforming machinery ensures that manufacturers like LS can adapt to the ever-changing demands of their clients. The company's commitment to ISO 9001:2015 certification and the expansion of services across more than 150 countries underscores its dedication to quality and customer satisfaction. As the need for innovative, lightweight, and resilient materials grows, the advantages of hydroforming remain integral to the field of advanced manufacturing.

Hydroforming vs stamping is a debate that highlights the technological evolution in manufacturing processes. While stamping remains a staple for high-volume production of simpler parts, hydroforming excels where intricate and non-uniform thicknesses are required. This distinction makes hydroforming a go-to choice for projects that demand both complexity and durability.

As the industry moves forward, LS Hardware Tech Co., Ltd continues to embrace new challenges, fostering an environment of continuous improvement. The integration of hydroforming technology represents just one facet of the company’s innovation-driven approach, aimed at empowering clients to bring their ideas to fruition. By remaining at the forefront of technological advancements, LS helps shape the future of manufacturing, ensuring that clients receive not only products but a partnership built on trust, expertise, and shared success.

The excitement surrounding the future of hydroforming applications indicates promising trends that will only enhance LS's capability to meet diverse manufacturing needs. The use of hydroforming sheets provides a versatile platform for creating bespoke components, enabling industries to achieve unprecedented levels of design flexibility and efficiency. This ability to cater to a wide range of application requirements solidifies hydroforming's role as a key contributor to the evolution of industrial fabrication.

In conclusion, the hydroforming process is more than just a manufacturing technique; it is a catalyst for innovation across numerous fields. Companies like LS Hardware Tech Co., Ltd are leading the charge in harnessing its potential, poised to continue delivering exceptional solutions that elevate both form and function. The synergy between hydroforming technology and the dedicated efforts of industry leaders promises a future where precise and efficient production is a standard, paving the way for groundbreaking advancements in manufacturing excellence.

Exploring Hydroforming Process: Advantages & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Revolutionizing Manufacturing with Hydroforming Techniques

Exploring the Hydroforming Process: Applications, Advantages & Technology

Revolutionize with Innovative Hydroforming Technology

Exploring Hydroforming Technology: Advancements and Applications

Exploring Hydroforming Process: Advantages & Applications

Revolutionizing Part Fabrication: The Hydroforming Process