In the ever-evolving world of manufacturing, the hydroforming process has become a game-changer, enabling the production of more lightweight, durable and precisely crafted metal parts. As industries continue to push for advancements in efficiency and quality, understanding the applications and advantages of hydroforming technology is vital.

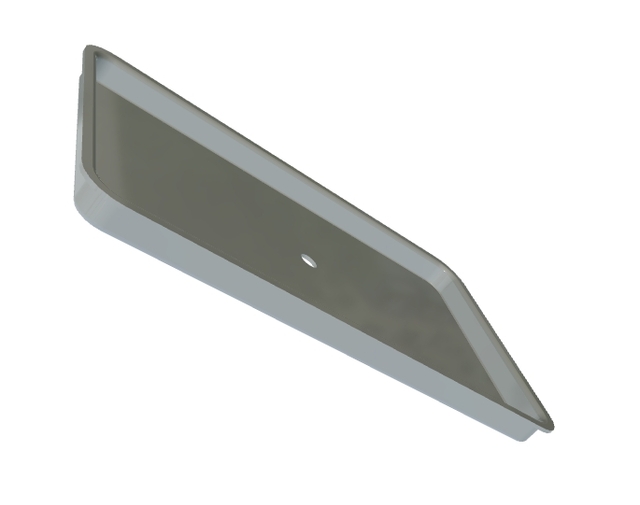

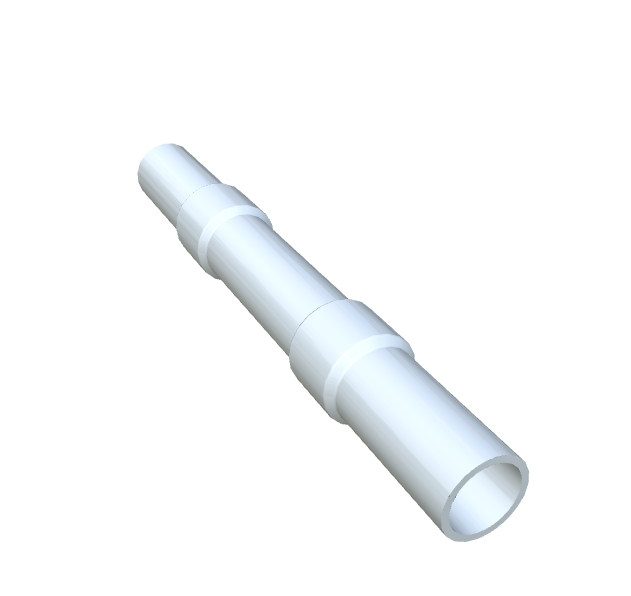

The **hydroforming process** is a specialized forming technique used to shape metals, like aluminum, steel, and brass, into complex shapes using high-pressure hydraulic fluids. This innovative method has found significant traction among manufacturers due to its ability to create intricate shapes and designs without the need for welding or added materials, making it a highly cost-effective solution. Hydroforming applications span across various industries including automotive, aerospace, and medical equipment. These sectors benefit greatly from the process's ability to produce seamless parts that reduce the overall weight of products without sacrificing structural integrity.

LS Hardware Tech Co., Ltd, a leading company in the manufacturing sector, embodies the principles of innovation and quality with its hydroforming technology. Established by Mr. Nick Zhang and a skilled team of engineers, LS stands out as a premier provider of high-precision parts with over 20 years of experience. The company is distinguished by its extensive use of high-end machining centers, which support the manufacturing of superior hardware and plastic components. The ISO 9001:2015 certified company prides itself on its versatility and efficiency, offering services to more than 5,000 clients in over 150 countries globally.

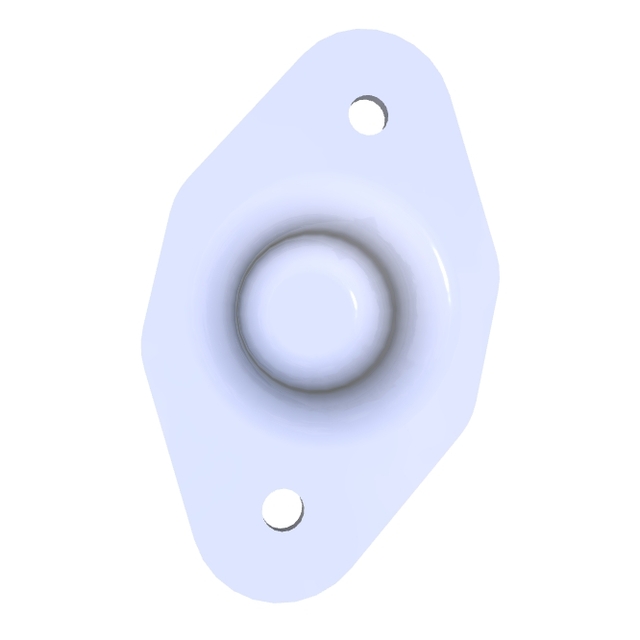

In terms of advancing water filtration systems, LS Hardware Tech Co., Ltd has introduced the SmartWater Filter Capsule. This product exemplifies their commitment to excellence and innovation in product design. The capsule features a polished, glossy exterior designed to seamlessly integrate into modern kitchens and utility spaces. Its high-precision hexagonal connector ensures a secure, leak-proof fit with existing water setups, enhancing the filtration process considerably. This embodies the company's mission to blend simplicity with sophistication by offering easy installation and maintenance.

With the trend towards sustainable living, products like the SmartWater Filter Capsule reflect a shift towards eco-friendly solutions that do not compromise on style or efficiency. The SmartWater Filter Capsule has an advanced multi-stage filtration system that effectively reduces impurities, making every drop of water it filters as pure and refreshing as possible. This not only aligns with the evolving consumer demand for healthier living solutions but also demonstrates LS's forward-thinking approach to manufacturing.

The adoption of hydroforming metal parts in sectors like the automotive industry showcases the technology's capability to replace traditional manufacturing techniques like stamping. Hydroforming vs stamping stands out due to its ability to form complex parts with greater material efficiency and reduced wastage. This makes hydroforming not just a cost-efficient alternative but also an environmentally friendly one.

In aerospace and medical industries, the adoption of hydroforming technology has been significant. The precision and consistency offered by hydroforming allow manufacturers to produce lightweight and durable components essential for both fields. As the demand for precision-engineered parts continues to rise, hydroforming remains integral in meeting these emerging needs.

At the heart of LS's operations is a commitment to deliver innovative manufacturing solutions. This mission is increasingly crucial as industries surge forward into an era defined by rapid technological advancement and heightened consumer expectations. By continuously investing in the latest hydroforming technology and methodologies, LS Hardware Tech Co., Ltd ensures its place at the industry's forefront, meeting the diverse and evolving needs of its global clientele.

In conclusion, whether it's through high-precision manufacturing or intelligent design of everyday products like the SmartWater Filter Capsule, embodying the principles of the hydroforming process and advanced techniques like those offered by LS are vital in today's competitive landscape. As industries grow and adapt, hydroforming advantages, backed by proven expertise and commitment to quality, remain indispensable to offering durable, lightweight and intricate metal solutions that power tomorrow's innovations.

Exploring the Hydroforming Process: Applications, Advantages & Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Revolutionizing Manufacturing with Hydroforming Techniques

Exploring the Hydroforming Process: Applications, Advantages & Technology

Revolutionize with Innovative Hydroforming Technology

Exploring Hydroforming Technology: Advancements and Applications

Exploring Hydroforming Process: Advantages & Applications

Revolutionizing Part Fabrication: The Hydroforming Process