In the ever-evolving world of manufacturing, the demand for innovative fabrication processes has led to the growing popularity of hydroforming techniques. As industries seek enhanced precision, versatility, and efficiency, the hydroforming process shows vast potential in transforming metal shaping industries. LS Hardware Tech Co., Ltd, renowned for its forward-thinking approach, exemplifies how the application of hydroforming technology can lead to groundbreaking advancements like their latest product, the Cylinder Slot Connector.

Hydroforming, a forming process that uses a high-pressure fluid to shape metals, offers distinct advantages over traditional stamping methods. Metal hydroforming enables manufacturers to achieve complex shapes and fine details without compromising the material's integrity. It's particularly beneficial for industries requiring lightweight yet sturdy components, such as automotive and aerospace sectors. Unlike stamping, which can result in a less accurate final product due to material stretching and thinning, hydroforming applies uniform pressure, maintaining consistent thickness and strength across the piece.

At the core of LS Hardware Tech Co., Ltd's success within the manufacturing domain is their adept use of advanced hydroforming machines. Founded by Nick Zhang, LS Hardware Tech embodies over two decades of expertise in hardware and plastic part manufacturing. The company prides itself on operating over 100 high-end machining centers that facilitate efficient and high-quality production through cutting-edge technology. Their ISO 9001:2015 certification ensures that every product, including high-precision parts tailored for various industries, meets the highest standards of quality and reliability.

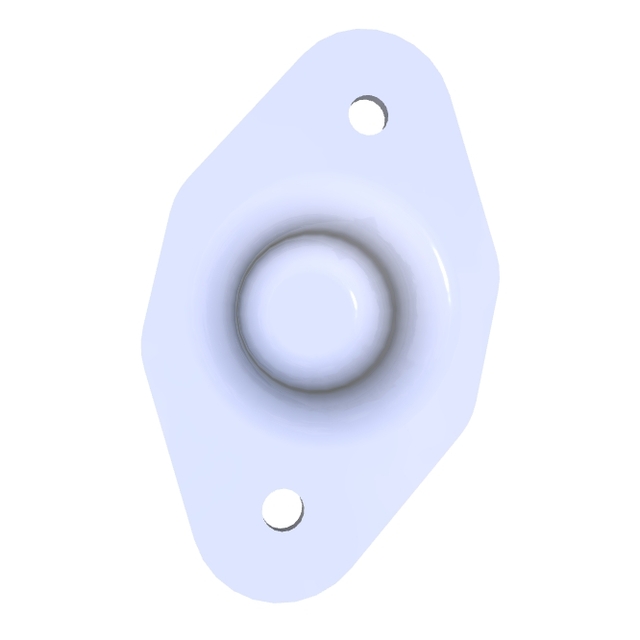

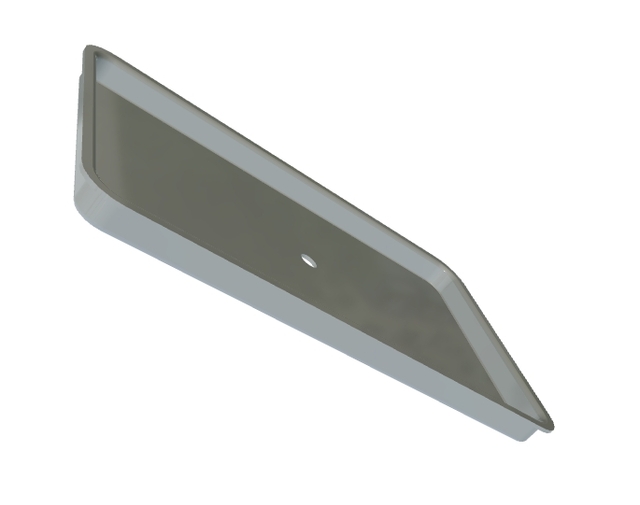

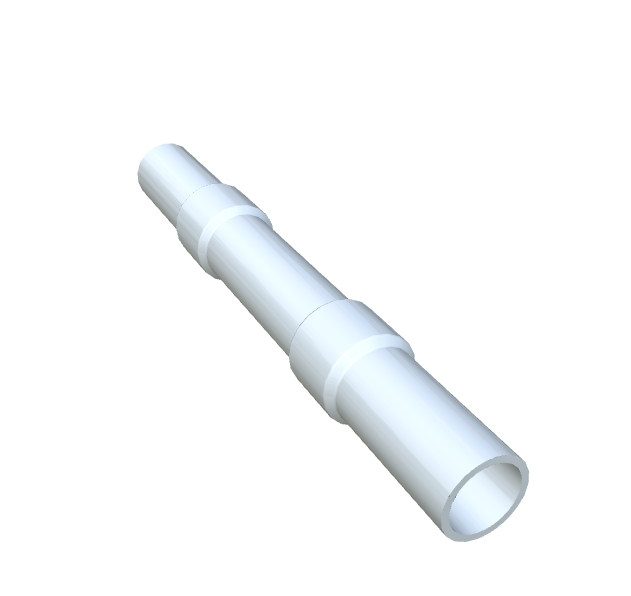

Among LS Hardware's suite of innovative products is the Cylinder Slot Connector—an emblem of hydroforming applications at their finest. This ingenious device, crafted with durable materials, showcases a cylindrical shape featuring two distinct horizontal slots and rounded holes for perfect integration into diverse projects. Beyond its practical functionality, the connector's sleek and modern design adds an aesthetic edge to engineering, construction, and creative DIY projects. It's a testament to the possibilities hydroforming techniques can deliver—marrying style with utility, thus enriching the appearance and structural integrity of projects.

Hydroforming technology's advantages extend far beyond the realm of design options. Its environmental benefits cannot be overstated. By requiring fewer materials for equivalent strength and allowing for minimal post-processing, such as trimming or welding, hydroforming significantly reduces waste. This makes it a sustainable choice in alignment with global environmental standards—one that LS Hardware Tech integrates into its mission to lead the charge in innovative, eco-friendly solutions.

Notably, LS Hardware caters to a vast clientele worldwide, from small-scale entrepreneurs to large factories, with their services extending across 150 countries and regions. Their prowess in high-precision part production for various sectors positions them as global industry leaders, pushing the envelope in hydroforming applications that open new vistas of commercial possibilities.

LS Hardware's commitment to empowering clients with inspiring solutions sees them continually advancing their manufacturing processes. By leveraging hydroforming technology to realize the full potential of products such as the Cylinder Slot Connector, they are charting new trails in engineering excellence that others in the industry aspire to follow. As industries pivot towards future-forward technologies, hydroforming promises to remain pivotal in shaping sustainable, cost-effective, and high-quality solutions for tomorrow's manufacturing challenges.

In conclusion, the evolving landscape of manufacturing requires processes that offer the utmost in precision, versatility, and reduced environmental impact. The hydroforming process, with its distinct advantages over traditional techniques, stands at the forefront of meeting these industry needs. LS Hardware Tech Co., Ltd exemplifies the potential of hydroforming techniques to innovate and revolutionize manufacturing, delivering products like the Cylinder Slot Connector that epitomize quality and functionality. Through their adept application of this technology, LS Hardware is not merely producing components but crafting solutions that empower visionaries to bring their ideas to life, setting a paradigm for excellence in the manufacturing industry.

Revolutionizing Manufacturing with Hydroforming Techniques

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Revolutionizing Industries: Hydroforming Process Advantages & Applications

Revolutionizing Manufacturing with Hydroforming Techniques

Exploring the Hydroforming Process: Applications, Advantages & Technology

Revolutionize with Innovative Hydroforming Technology

Exploring Hydroforming Technology: Advancements and Applications

Exploring Hydroforming Process: Advantages & Applications

Revolutionizing Part Fabrication: The Hydroforming Process