The realm of welding is vast, filled with numerous techniques that cater to the specific demands of various projects. At the heart of this intricate world is the need for proper welding techniques, a crucial skill that transforms raw materials into robust, functional structures. For any enthusiast or professional looking to master the art, understanding and implementing effective welding techniques is fundamental.

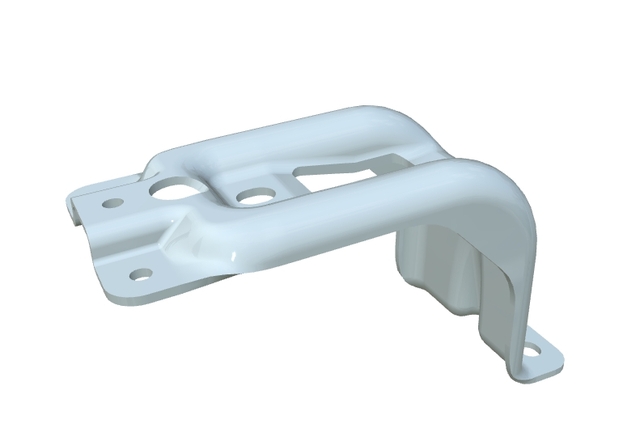

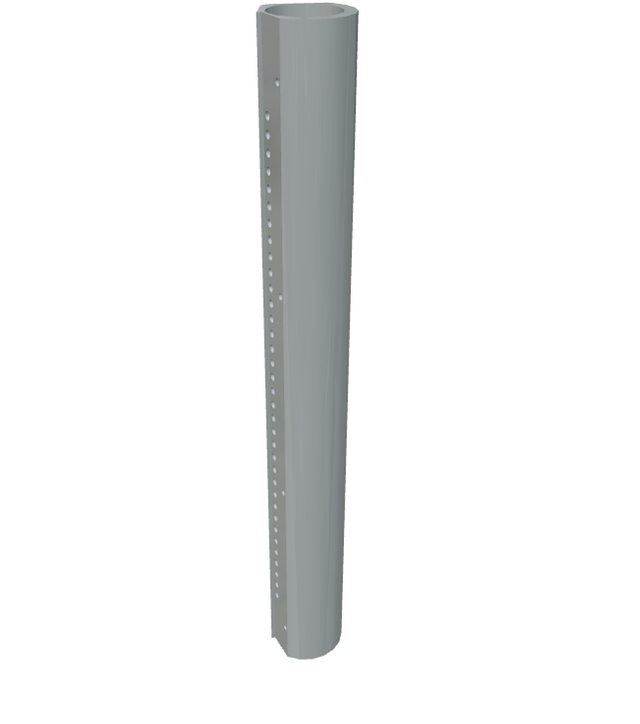

Welding techniques encompass several prominent methods, each suited to different applications and materials. One popular technique is TIG welding (Tungsten Inert Gas), known for producing precise, high-quality welds. This technique is often used in applications where aesthetics and precision are paramount, such as in the creation of the Stainless Steel Perforated Hollow Rod. Crafted from high-quality stainless steel, this rod benefits from the clean, controlled nature of TIG welding, ensuring each perforation and joint is meticulously executed.

MIG welding (Metal Inert Gas) is another widely used technique, prized for its speed and efficiency. It’s a go-to method for many industrial projects due to its ability to produce clean welds quickly, without the need for extensive post-weld cleaning. In the construction of versatile components like the Stainless Steel Perforated Hollow Rod, MIG welding is instrumental in achieving robust joints that withstand both indoor and outdoor environmental stresses.

Stick welding, or Shielded Metal Arc Welding (SMAW), though more traditional, remains popular for its simplicity and effectiveness in outdoor environments. Its versatility allows it to be used with a wide variety of metals, making it an invaluable technique for installing or modifying components such as the stainless steel rod in environments prone to moisture or corrosion.

The importance of welding safety cannot be understated, with safety gear and practices being integral elements of any welding operation. Whether engaging in TIG, MIG, or stick welding, proper safety measures such as protective clothing, helmets, and eye protection are essential to prevent accidents and ensure the wellbeing of the welder.

Equally crucial to the welding process is the use of appropriate welding equipment and supplies. These not only include the welding machines themselves but also incorporate tools like clamps, grinders, and ventilation systems that support the welding process and enhance the final product’s integrity and finish. In the production of the Stainless Steel Perforated Hollow Rod, top-tier welding supplies are a necessity to achieve the precision and durability that the product is renowned for.

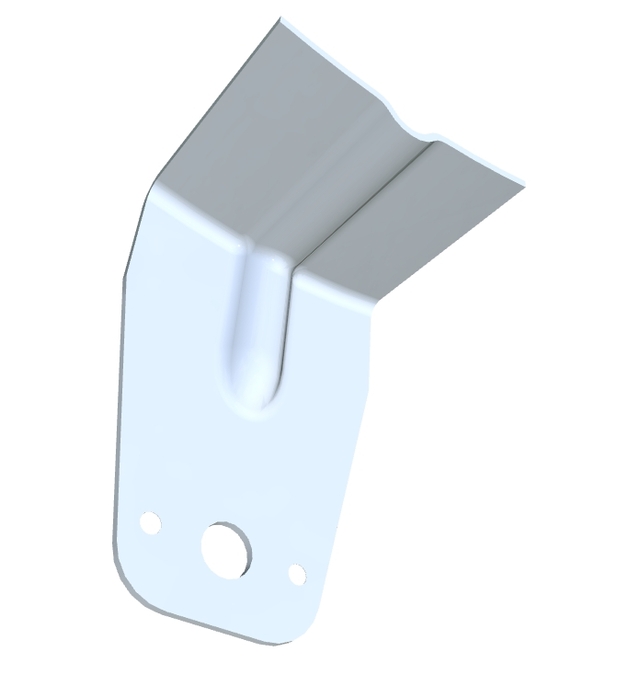

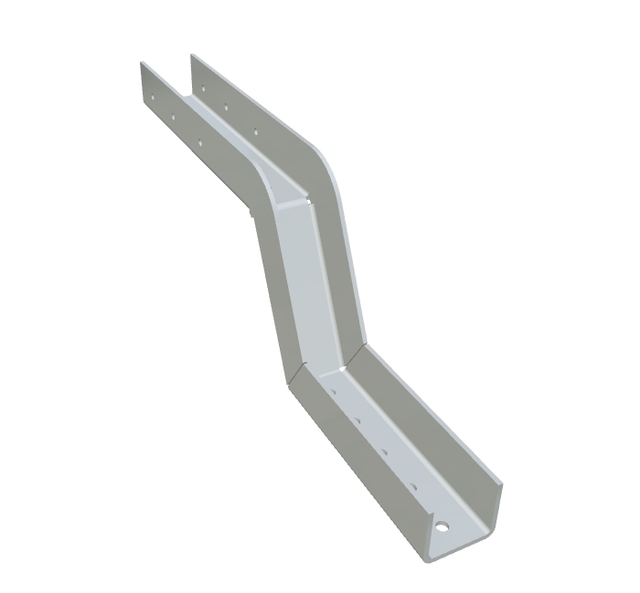

For those seeking formal validation of their welding skills, obtaining welding certification is a worthwhile pursuit. This not only enhances a welder’s credibility but also opens doors to more challenging and rewarding projects. Certified welders are often sought after for high-profile projects requiring rigorous standards, such as those involving critical support components like the Stainless Steel Perforated Hollow Rod, designed for use in architectural or engineering contexts where both strength and aesthetics are vital.

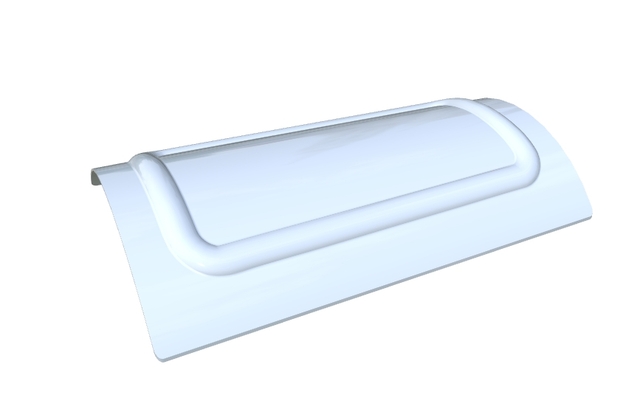

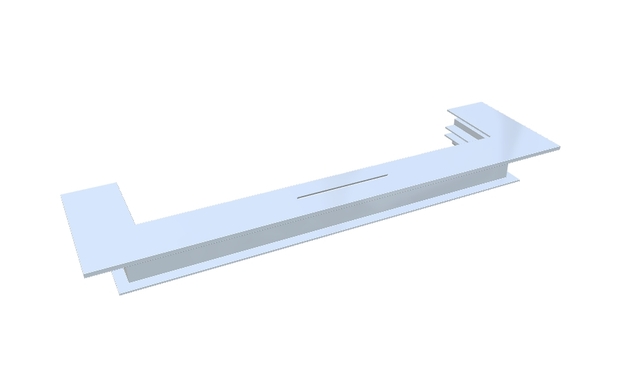

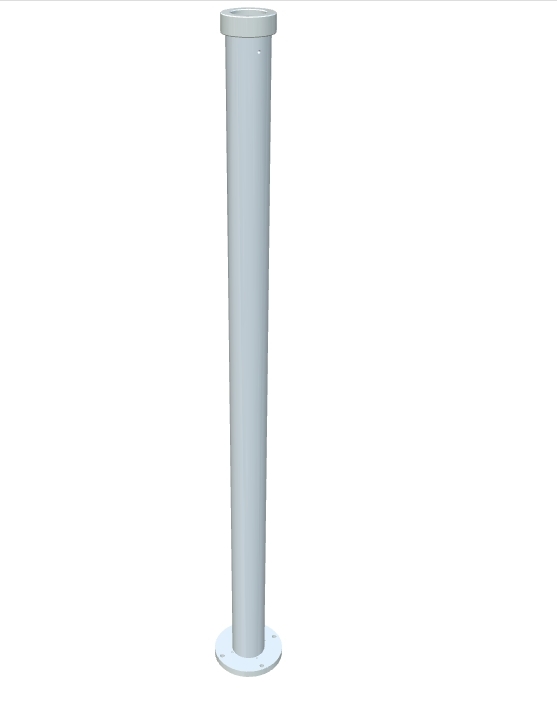

The Stainless Steel Perforated Hollow Rod itself is a testament to the wonders of modern engineering, a product that seamlessly integrates form and functionality. Constructed with meticulous attention to detail, its perforations offer practical benefits such as enhanced ventilation and drainage, making it ideal for installations in moisture-prone environments. Moreover, its lightweight yet robust nature makes it an indispensable element in both artistic and structural projects.

Incorporating such versatile components into one's design or construction framework broadens the creative possibilities, allowing architects, designers, and DIY enthusiasts to innovate beyond conventional constraints. Whether for reinforcing frameworks or creating custom metalwork projects, the rod’s elegant appeal and utility make it a standout choice.

Ultimately, mastering various welding techniques while utilizing products like the Stainless Steel Perforated Hollow Rod empowers professionals to execute projects with a blend of strength, precision, and style. With the perfect harmony of skilled craftsmanship and quality materials, any project can reach new heights of excellence, demonstrating the transformative power of modern welding technologies.

Mastering Welding Techniques: Elevate Your Projects

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Welding Techniques for Industrial Excellence

Exploring Types of Welding: Techniques, Safety, and More

Welding Safety: Ensuring Safe Welding Practices

Mastering Welding Techniques: Types, Safety, and Equipment

Master Welding Techniques for Architectural Brackets

Mastering Welding Techniques: Elevate Your Projects

Mastering Welding Techniques for Modern Urban Safety

Mastering Welding Techniques: Weld Safely with Innovation