In the ever-evolving world of construction and industrial projects, mastering various welding techniques is essential for professionals and DIY enthusiasts alike. Understanding different types of welding such as MIG welding, TIG welding, stick welding, and more is crucial for ensuring the structural integrity and durability of any project. Whether you're engaged in architectural design or assembling heavy-duty shelving systems, the right welding techniques can dramatically enhance the functionality and lifespan of your creations.

**An Overview of Welding Techniques**

To start, it's vital to understand the plethora of available welding techniques. MIG welding, or Gas Metal Arc Welding (GMAW), is favored for its efficiency and is ideal for thicker materials, making it a popular choice in automotive repairs and construction. TIG welding, on the other hand, offers precision and control, making it suitable for tasks requiring fine finish – a favorite in the aerospace industry. Stick welding, known for its simplicity and adaptability to outdoor conditions, is valued for tasks involving heavy metals like iron and steel. Each technique has its unique place within a welder's toolkit, offering specific advantages depending on the project's requirements.

Welding safety is paramount, regardless of the technique chosen. Ensuring the availability of proper welding equipment, such as helmets, gloves, and protective clothing, is mandatory. Moreover, welding certification ensures that professionals are well-versed with safety standards and procedures. These certifications not only boost one's confidence but also open doors to diverse welding jobs. Whether employed in construction, automotive, or even manufacturing sectors, qualified welders are indispensable contributors to industry success.

**Introducing the Innovative Steel Angle Bracket**

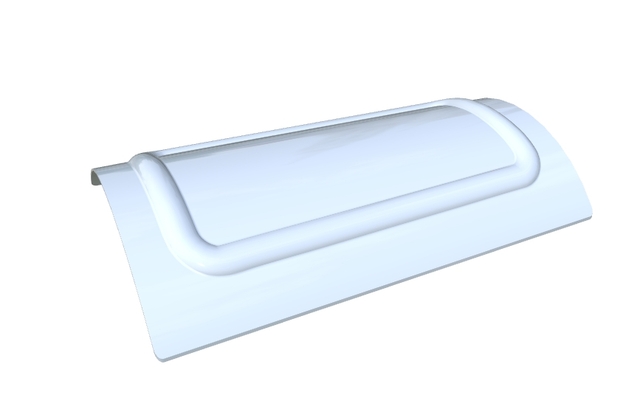

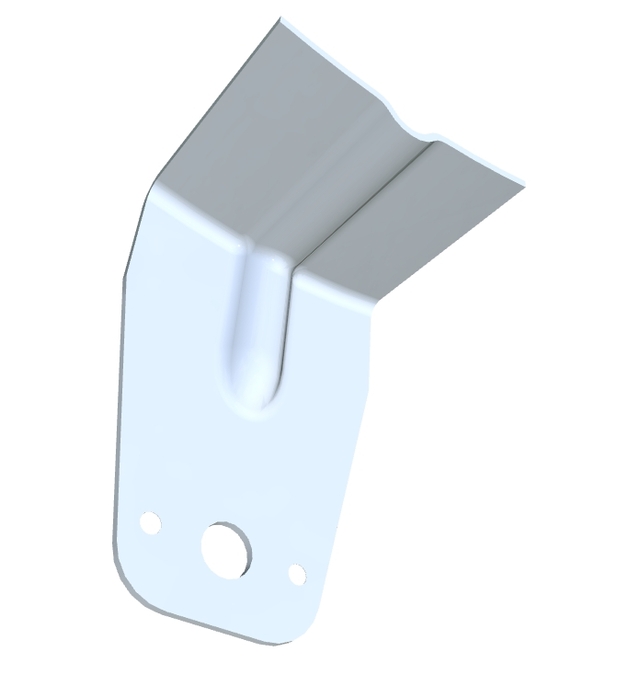

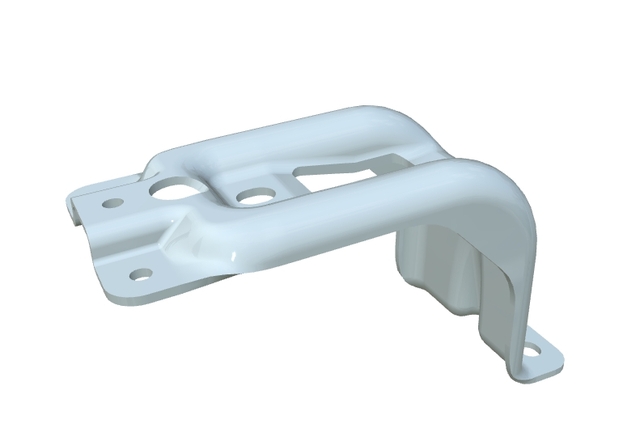

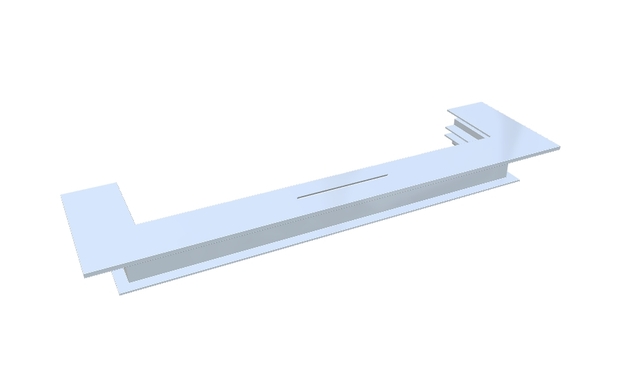

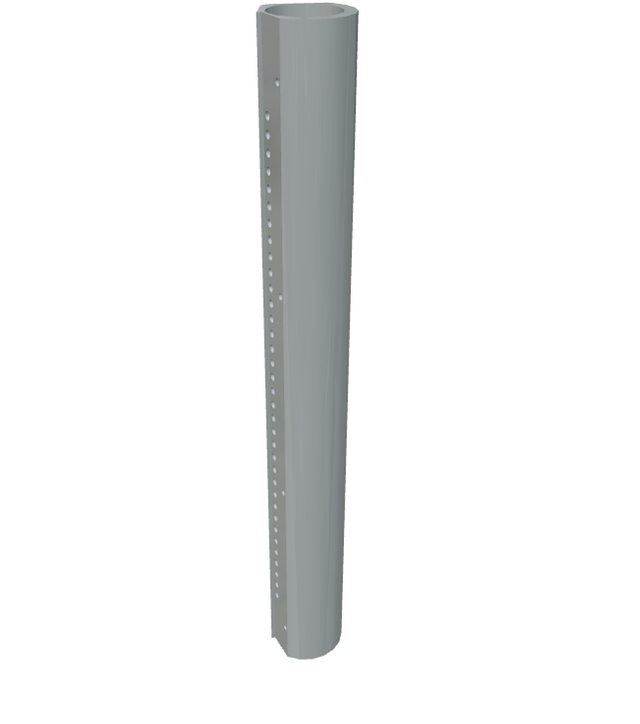

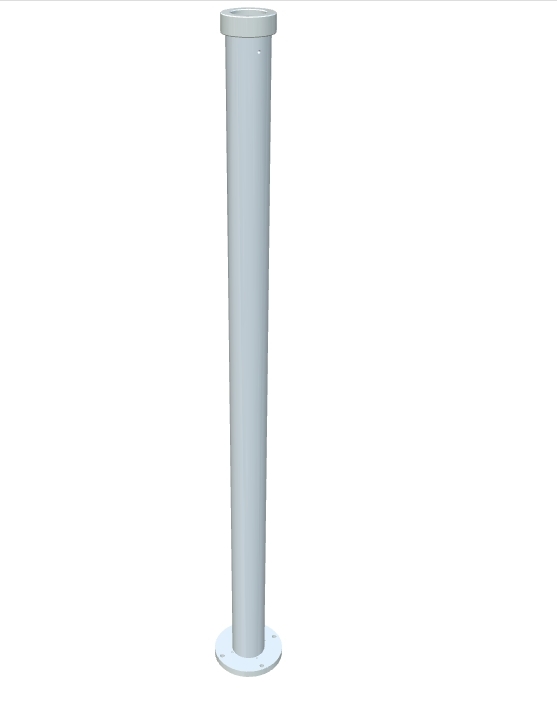

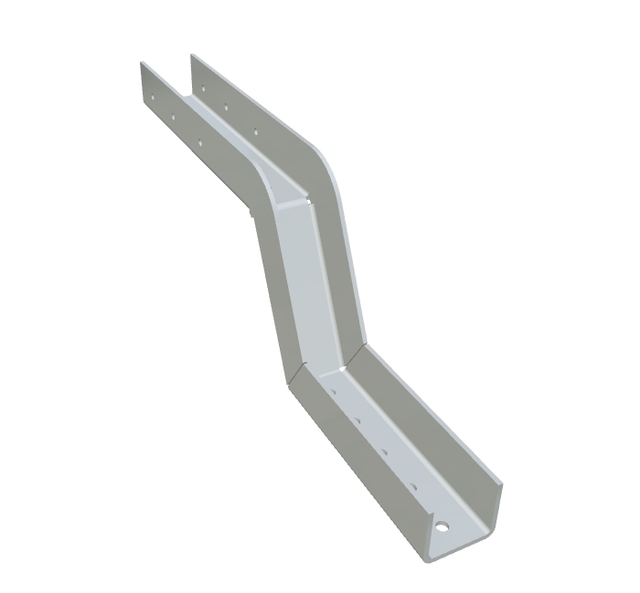

Amidst the array of welding projects, reliable support elements like the steel angle bracket play a pivotal role. We proudly introduce our steel angle bracket, a marvel of modern engineering designed to bolster both strength and versatility. Crafted from premium galvanized steel, our bracket guarantees formidable durability while resisting corrosion – a vital feature for enduring harsh environmental conditions. This matches perfectly with both minor DIY projects and ambitious architectural pursuits, thanks to its pre-drilled holes accommodating varied fastening methods.

The innovative multi-angle design of our bracket is specifically tailored to support complex architectural structures, ensuring unmatched reliability whether used in constructing massive edifices or intricate shelving systems. This unique design not only enhances structural soundness but also maintains a minimalist aesthetic, harmonizing with modern architectural trends. Architects and builders alike will appreciate the sleek design and professional adaptability it offers.

**Educational Paths and Career Opportunities in Welding**

Venturing into the welding realm often begins with comprehensive welding training and welding classes. These programs equip aspiring welders with the knowledge and hands-on experience needed to operate safely and efficiently. With the evolving landscape of welding, automated welding techniques are gaining significant traction, introducing technology-driven efficiency into the field. Welders proficient in both manual and automated techniques hold a distinct competitive advantage in the job market.

Furthermore, the rising demand for skilled welders underscores the need for ongoing professional development. Embracing different welding techniques and becoming adept at using various welding supplies and accessories only enhances one’s professional scope. Whether aiming to excel in welding inspection or seek managerial roles within construction firms, a solid grounding in welding fuels career progression.

In conclusion, mastering welding techniques not only facilitates superior construction outcomes but also nurtures career growth. From choosing the right welding methods and tools to employing robust products like our steel angle bracket, welders and builders are better equipped to construct resilient and aesthetically pleasing structures. The blend of technical acumen and innovative products paves the way for groundbreaking accomplishments in the world of construction and industrial design. Embrace the diversity of welding, coupled with the advancements in welding accessories and equipment, to unleash your full potential in this dynamic industry.

Mastering Welding Techniques: Weld Safely with Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Welding Techniques for Industrial Excellence

Exploring Types of Welding: Techniques, Safety, and More

Welding Safety: Ensuring Safe Welding Practices

Mastering Welding Techniques: Types, Safety, and Equipment

Master Welding Techniques for Architectural Brackets

Mastering Welding Techniques: Elevate Your Projects

Mastering Welding Techniques for Modern Urban Safety

Mastering Welding Techniques: Weld Safely with Innovation