In today's rapidly evolving industrial landscape, sheet metal fabrication stands as a cornerstone, providing innovative solutions for countless applications across various sectors. Companies like LS Hardware Tech Co., Ltd have redefined the standards of excellence in this domain, offering a suite of advanced metal fabrication services that cater to the unique demands of their clients worldwide.

**Sheet Metal Fabrication: A Mastery of Precision and Innovation**

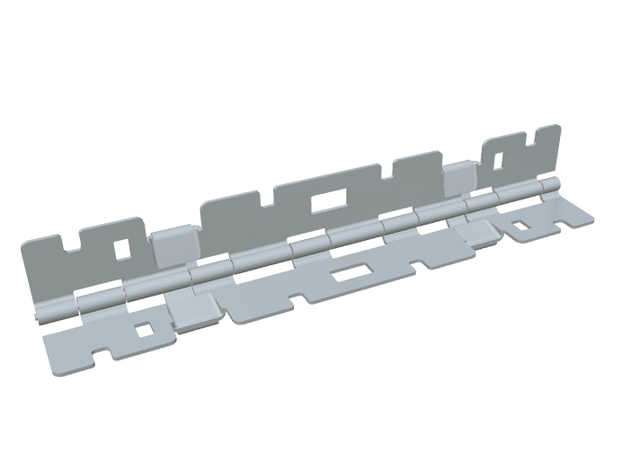

The process of sheet metal fabrication involves the meticulous crafting of metal sheets into desired shapes and products, through cutting, bending, and assembling processes. Key innovations in this field include CNC sheet metal cutting and laser cutting technologies, which allow for unparalleled precision and complexity in designs. For instance, the capability of CNC cutting ensures that even the most intricate designs can be realized with exact specifications, making it indispensable in custom sheet metal projects.

LS Hardware Tech Co., Ltd, a leader in metal fabrication services, excels in producing high-precision parts essential for industries such as automotive, aerospace, and medical devices. Founded by Nick Zhang, an expert with over two decades of experience, the company operates over 100 high-end machining centers, ensuring top-notch quality and efficiency in their production processes. Their reputation as a trusted partner extends globally, reinforced by their ISO 9001:2015 certification.

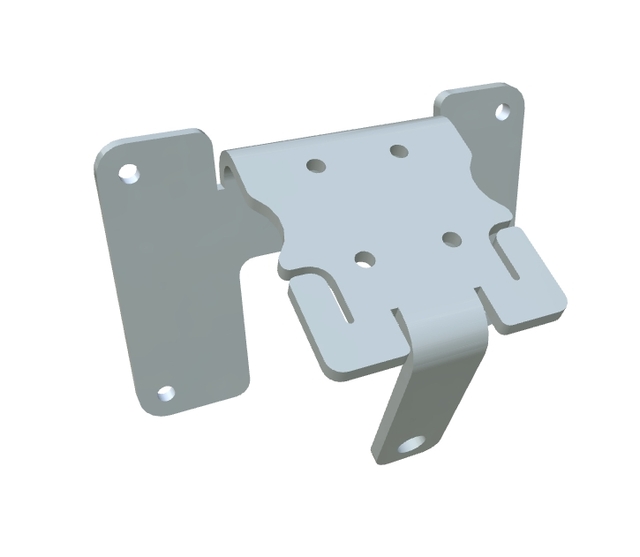

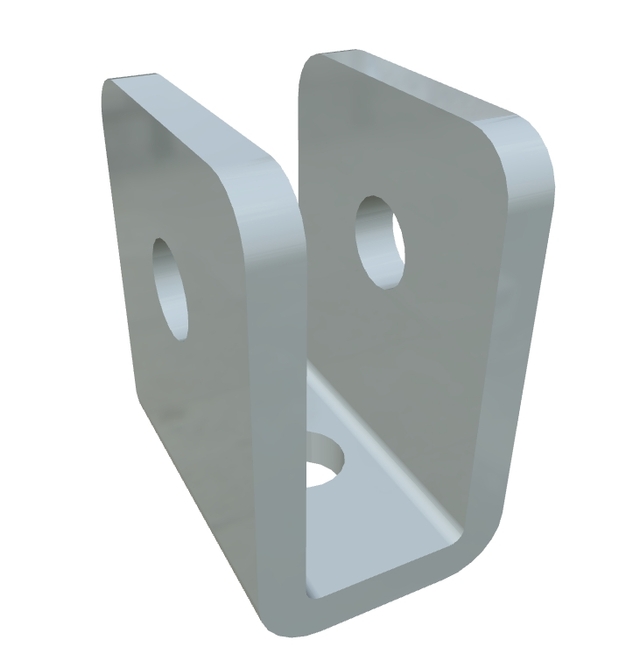

**Discover the Superior Mounting Bracket: Engineered for Excellence**

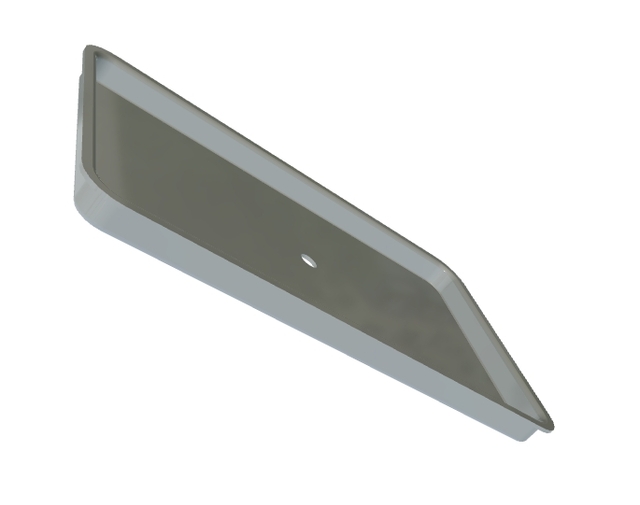

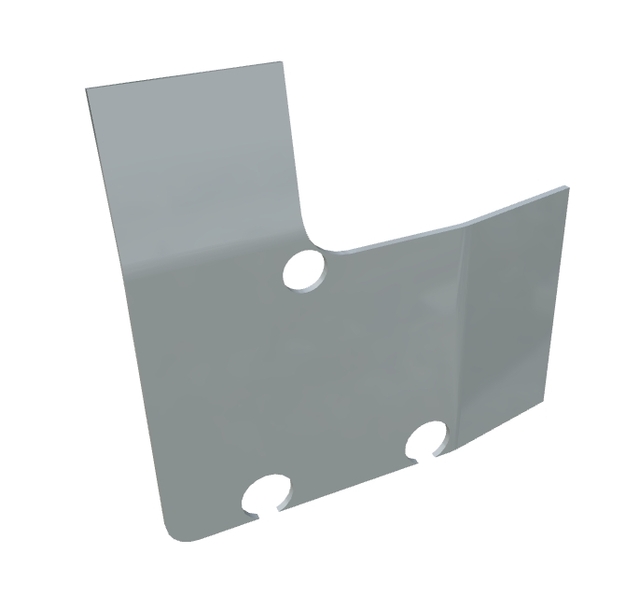

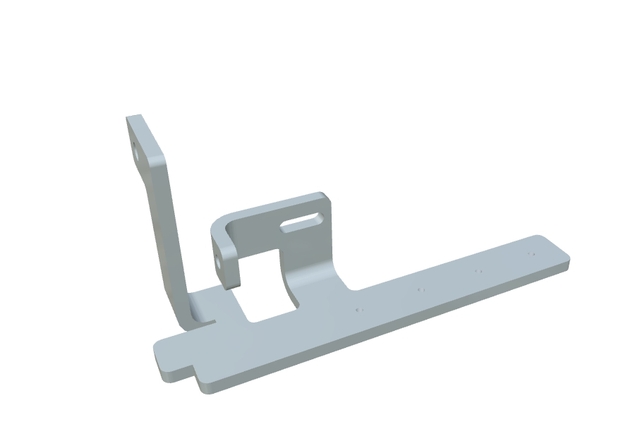

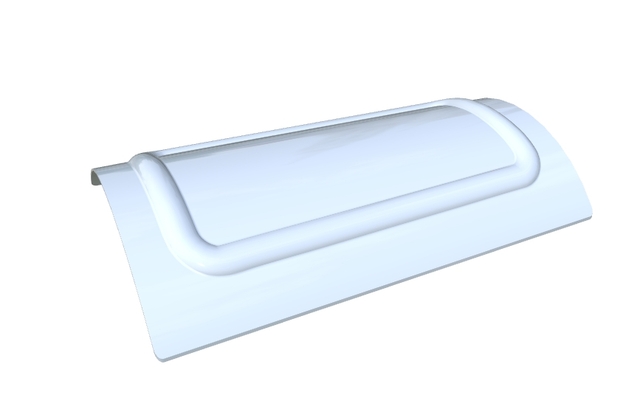

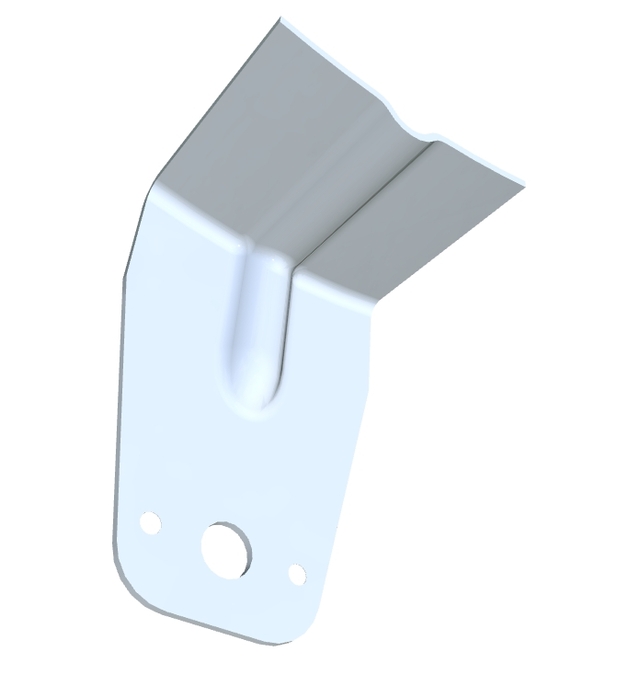

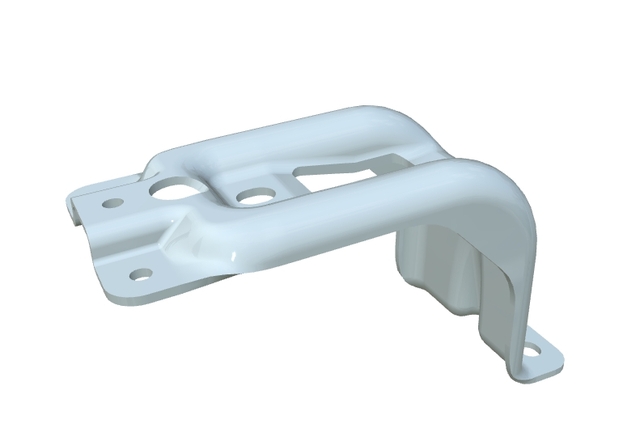

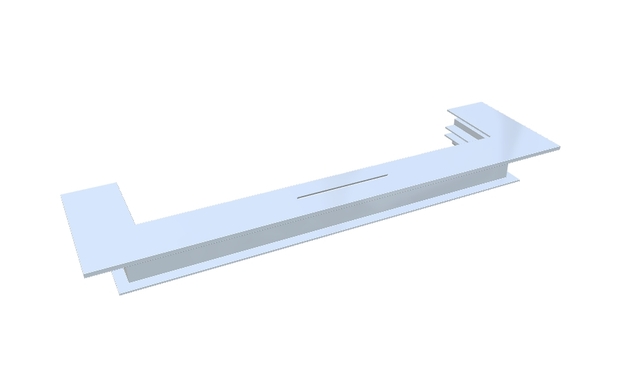

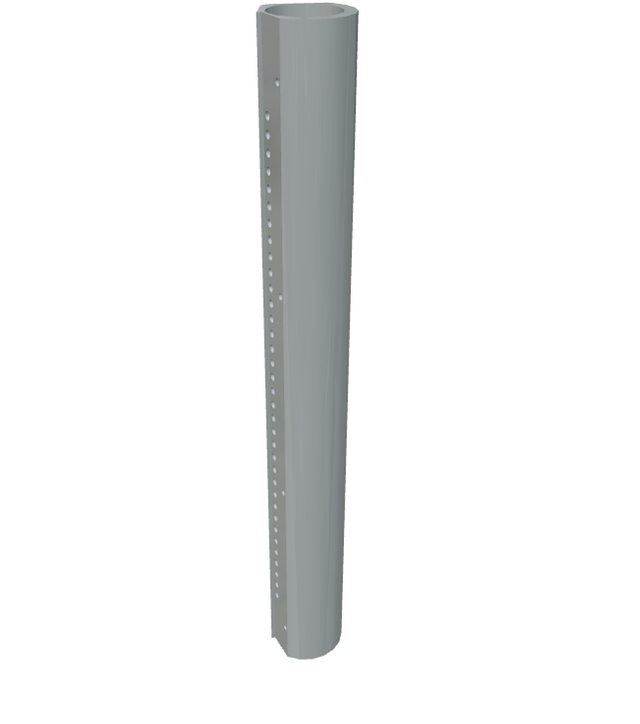

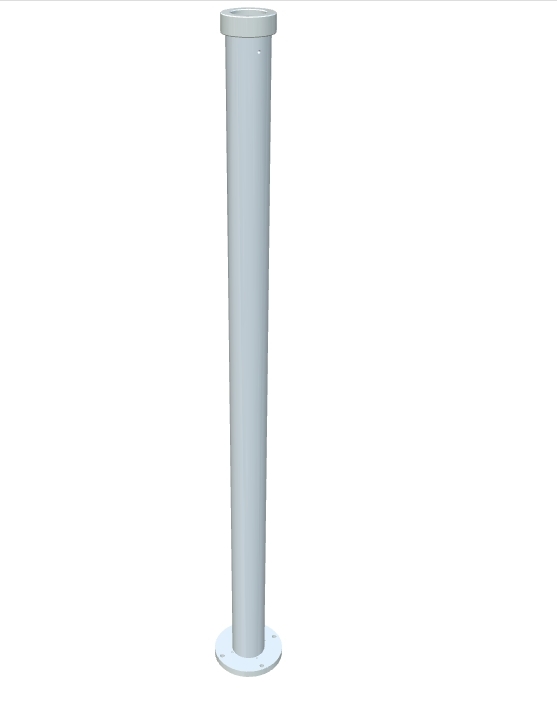

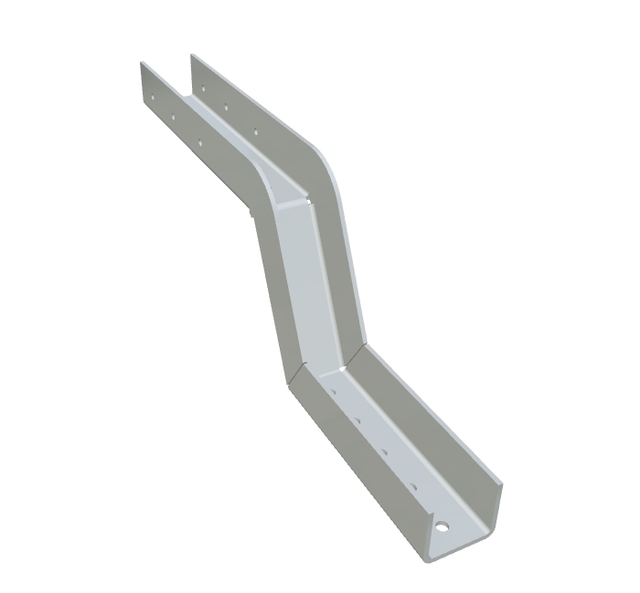

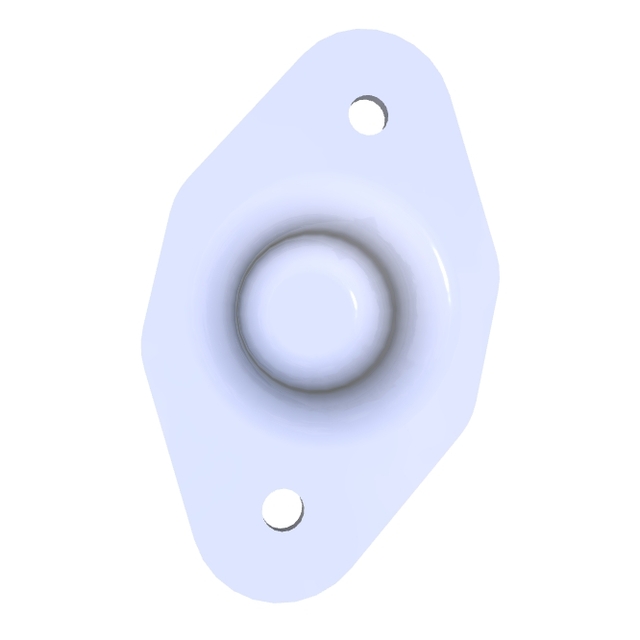

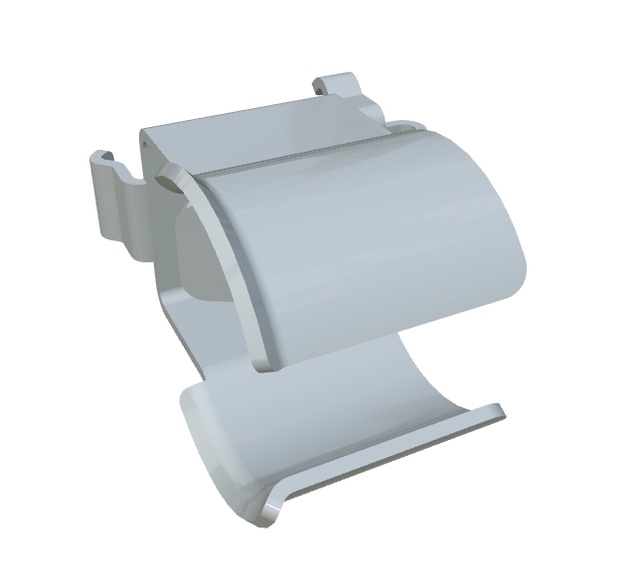

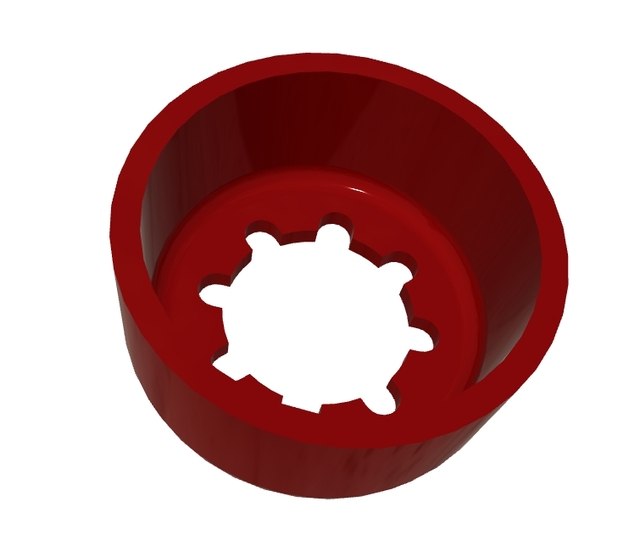

A prime example of the high-quality products stemming from LS's mastery in metal fabrication is their precisely engineered mounting bracket. This product, constructed from high-grade stainless steel, epitomizes durability and strength, making it an ideal choice for various demanding applications. Its robust U-shaped design offers superior support and stability, further enhanced by strategically placed holes that allow for versatile component securing. This makes the mounting bracket perfect for use in construction, automotive, and industrial environments.

Moreover, the mounting bracket features a polished finish that not only elevates its aesthetic appeal but also provides resistance to corrosion and wear. Such attributes are crucial in environments that demand both performance and style. Whether utilized in structural designs or intricate machinery, this bracket delivers reliability and elegance.

**Expanding Horizons: Custom and Aluminum Sheet Metal Fabrication**

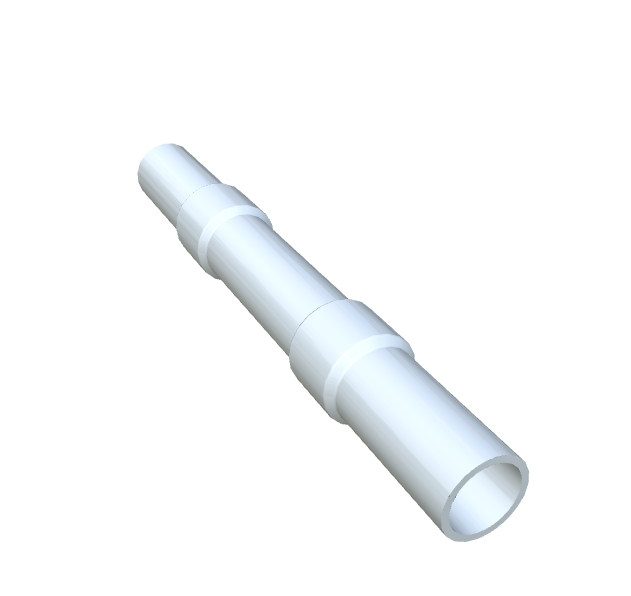

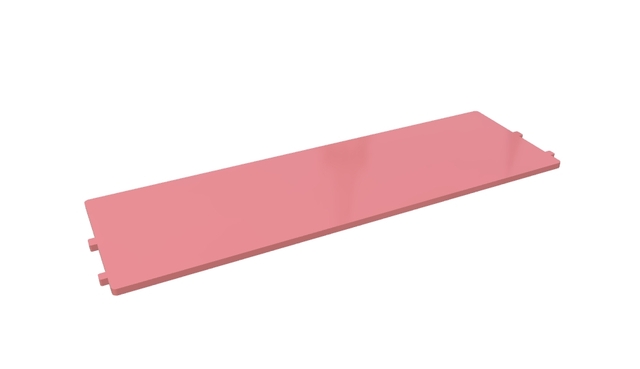

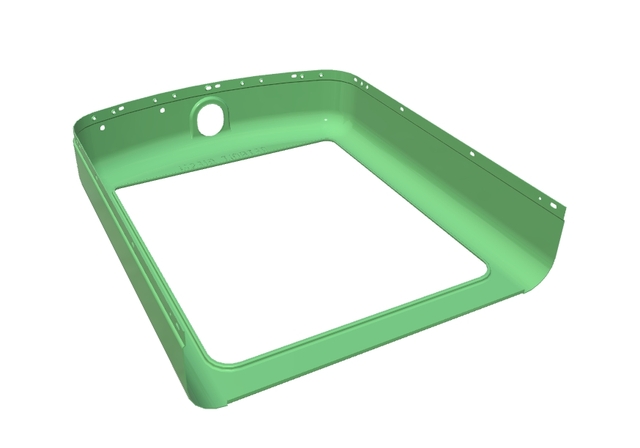

Beyond stainless steel fabrication, LS Hardware Tech excels in custom sheet metal solutions, including aluminum sheet metal fabrication. Aluminum, known for its lightweight yet sturdy properties, is a preferred material in industries where reducing weight without compromising strength is crucial, such as in aerospace and consumer electronics.

Laser cutting sheet metal and advanced metal bending services further expand the capabilities of custom projects, enabling the creation of complex geometries and precise specifications. These technologies facilitate prototyping and mass production alike, supporting clients' needs from concept to completion.

**Empowering Innovation Through Advanced Fabrication Solutions**

At the heart of LS Hardware Tech’s offerings is their commitment to empowering clients by delivering innovative manufacturing solutions. They take pride in their ability to bring ideas to life, constantly refining their processes and capabilities to meet the ever-evolving needs of their customers. Their extensive range of services and expertise makes them the preferred choice for major factories in China and beyond.

In summary, sheet metal fabrication is not just about shaping metal; it's about pushing the limits of innovation and craftsmanship. Whether you're looking for robust stainless steel solutions or lightweight aluminum alternatives, LS Hardware Tech Co., Ltd is equipped to transform your vision into reality. Through their dedication to precision and quality, they continue to set the benchmark in the fabrication industry, reaffirming their status as industry leaders committed to excellence and innovation.

Sheet Metal Fabrication: Precision & Excellence Unveiled

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering the Blanking Process: Precision in Metal Blanking

Exploring the Hydroforming Process: Advantages & Applications

Mastering Stamping Techniques in Modern Manufacturing

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process in Metal Fabrication