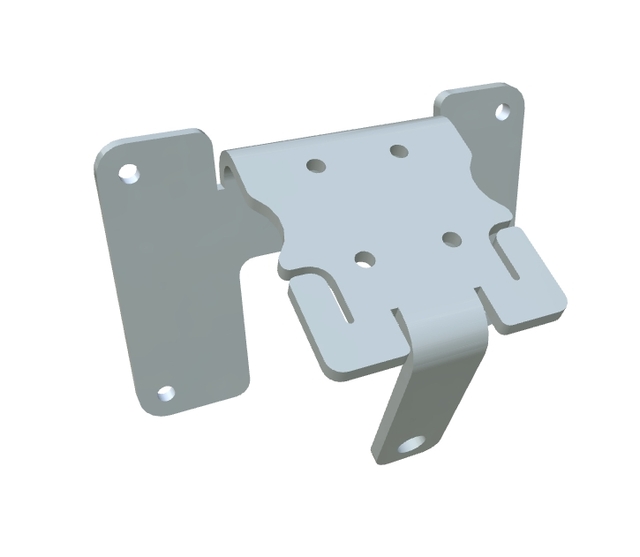

Metal bending has always been a critical part in engineering and manufacturing processes, providing the flexibility needed in design and construction. It’s a fundamental technique in the development of products such as the VESA Wall Mount Bracket, which beautifully combines both functionality and aesthetic appeal. Metal bending techniques ensure the robustness and versatility of this modern accessory, vital for securing screens in various settings.

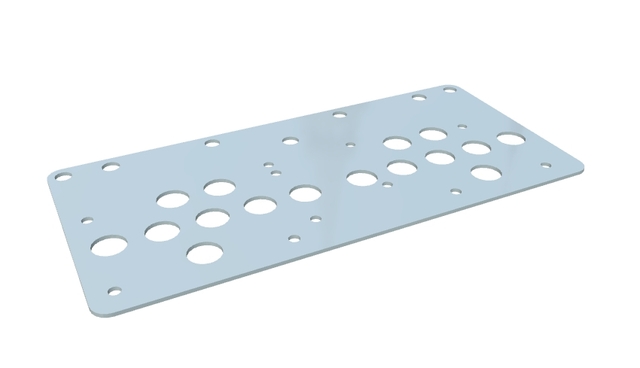

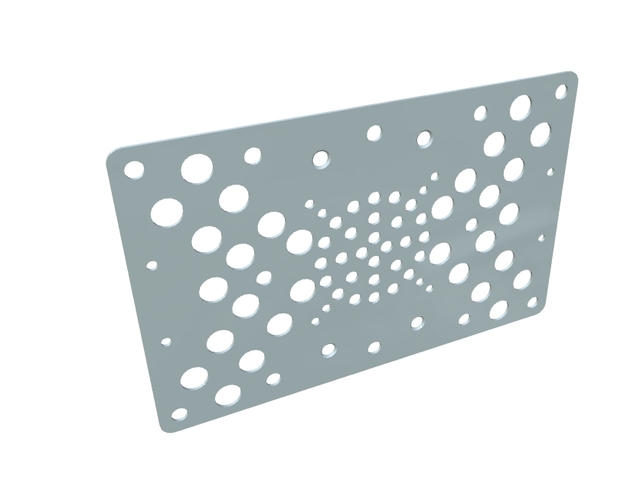

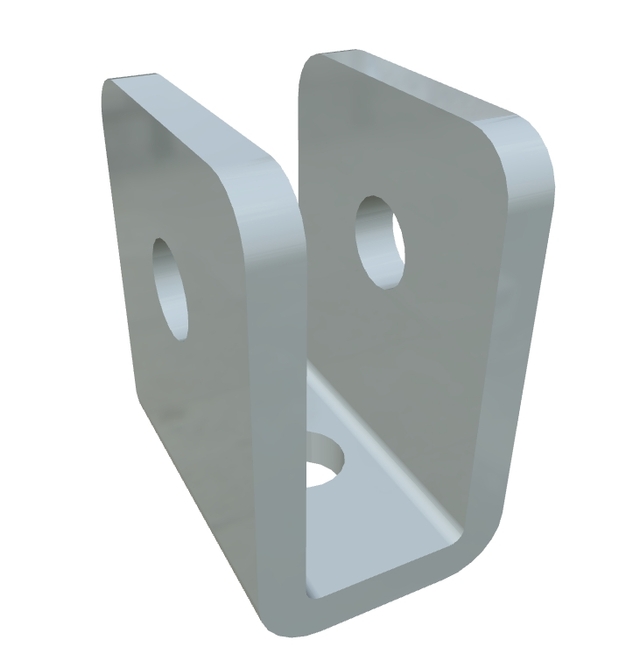

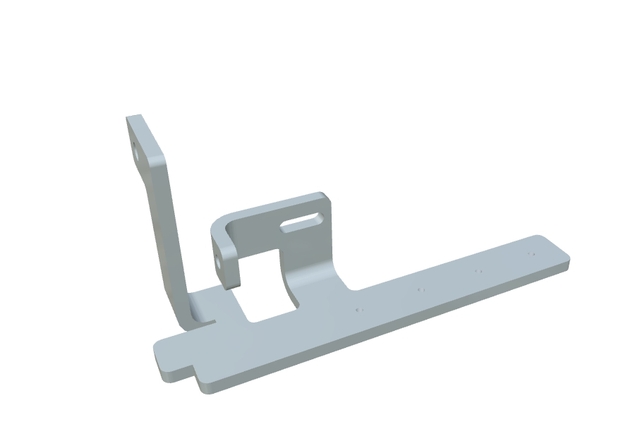

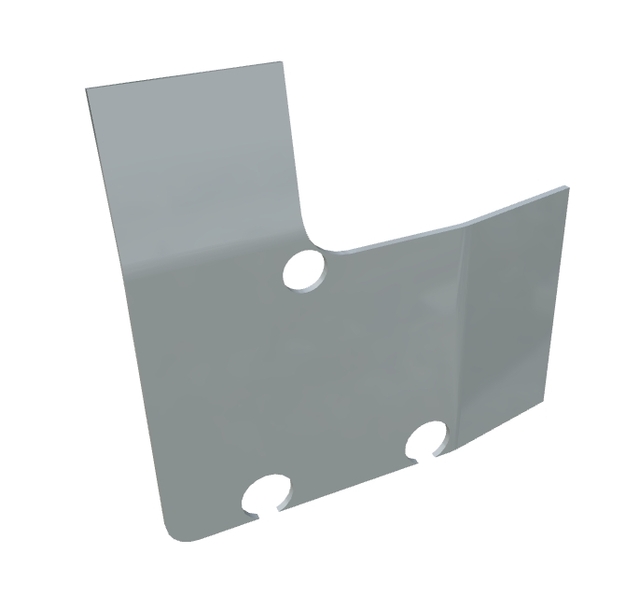

The process of bending metal involves numerous techniques that cater to different materials and product requirements. Techniques like pipe bending are essential in industries that require durable and reliable frame structures, while sheet metal bending is frequently employed for creating components in automotive and aerospace sectors. The VESA Wall Mount Bracket, for example, utilizes precise bending processes to achieve a sleek and minimalist design, accommodating a variety of devices with multiple mounting holes. This adaptability in design showcases the intricacies involved in the bending process, which not only affects the efficiency of the end product but also its visual integration into modern spaces.

Understanding bending forms and bending in engineering provides insight into the art and science of fabricating components that balance both strength and weight. The VESA Wall Mount Bracket exemplifies this balance with its elegant appearance that also saves space. The bending design employed in its construction offers stability and security while seamlessly blending with any interior setting. Whether in an office, home, or commercial environment, the use of advanced bending techniques in crafting this bracket highlights the innovation and practicality of metal bending in modern engineering.

The VESA Wall Mount Bracket is more than just a mounted accessory; it symbolizes the continuous advancements in metal bending processes that improve device compatibility and installation ease. The end product not only redefines the viewer's experience through enhanced multimedia setups but also showcases how meticulous engineering adds value. This is achieved by leveraging detailed bending designs and techniques vital in realizing a product that is as sturdy as it is sleek.

Metal bending remains a crucial element in engineering, embodying creativity, durability, and modern aesthetics. As exemplified by the VESA Wall Mount Bracket, effective bending processes lead to products that not only meet but exceed the demands of contemporary design and functionality.

Metal Bending: Techniques for Modern Engineering Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Bending Techniques: Essential in Modern Design

Mastering Bending Techniques for Innovative Designs

Mastering Bending Techniques for Modern Elegance

Mastering Bending Techniques with Precision Router Base Plate

Metal Bending: Techniques for Modern Engineering Design

Bending Technology: Revolutionizing Metal and Pipe Bending

Expert Bending Techniques for Advanced Manufacturing

Mastering Bending Techniques for Modern Applications