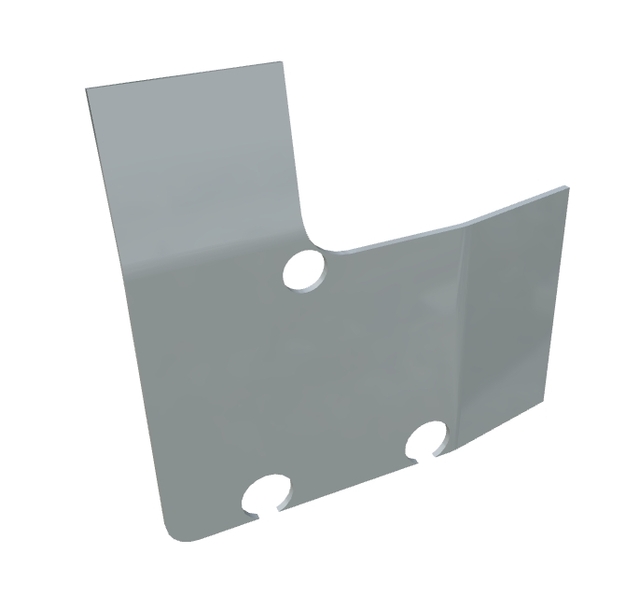

In a world driven by innovation and precision, sheet metal fabrication stands out as a pivotal process that underpins a multitude of industries. At LS Hardware Tech Co., Ltd, a leader in custom sheet metal and sheet metal manufacturing, our dedication to excellence is embodied in our latest offering: the Precision Stamped Metal Panel. These panels leverage state-of-the-art metals technology, perfectly marrying strength with versatility.

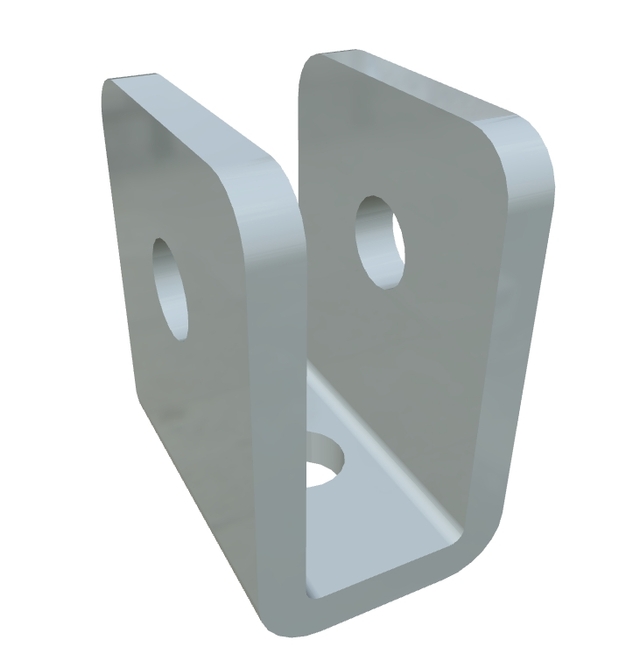

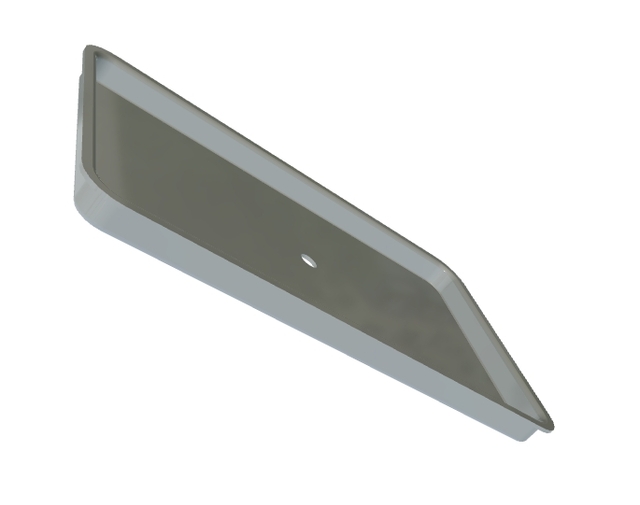

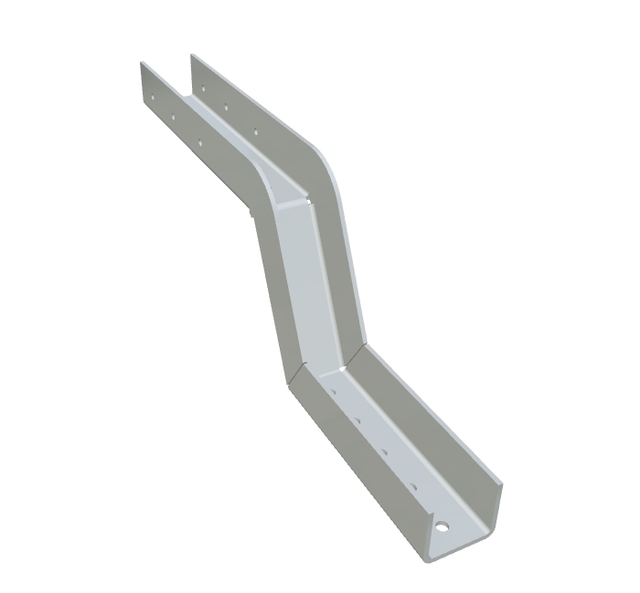

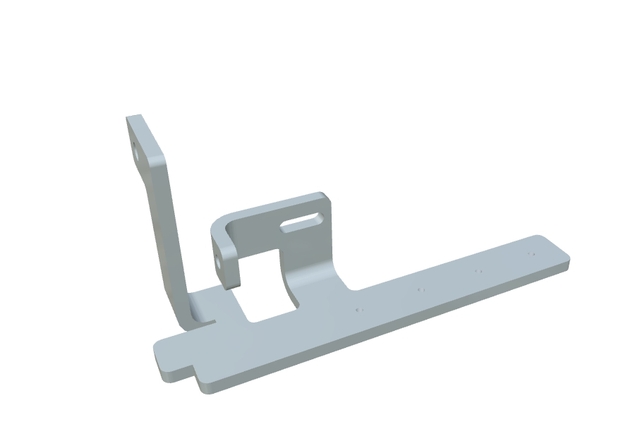

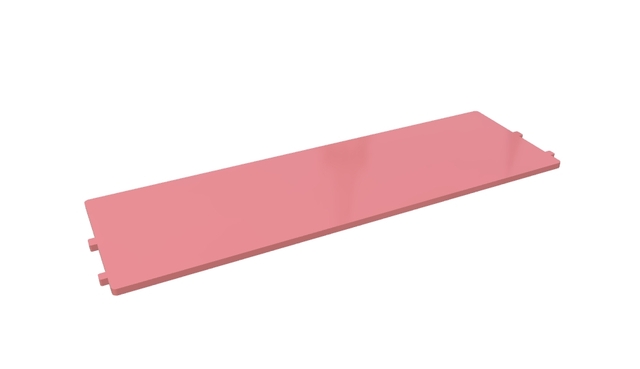

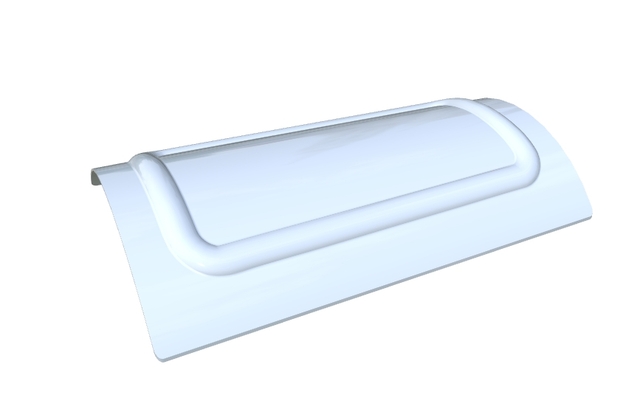

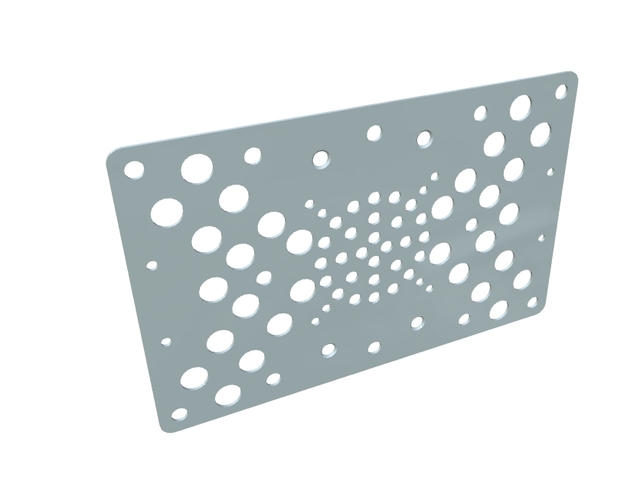

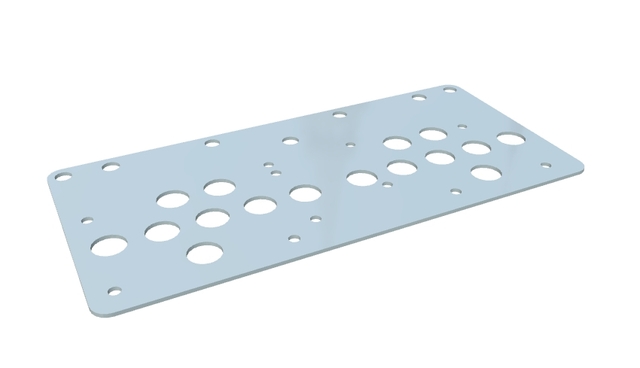

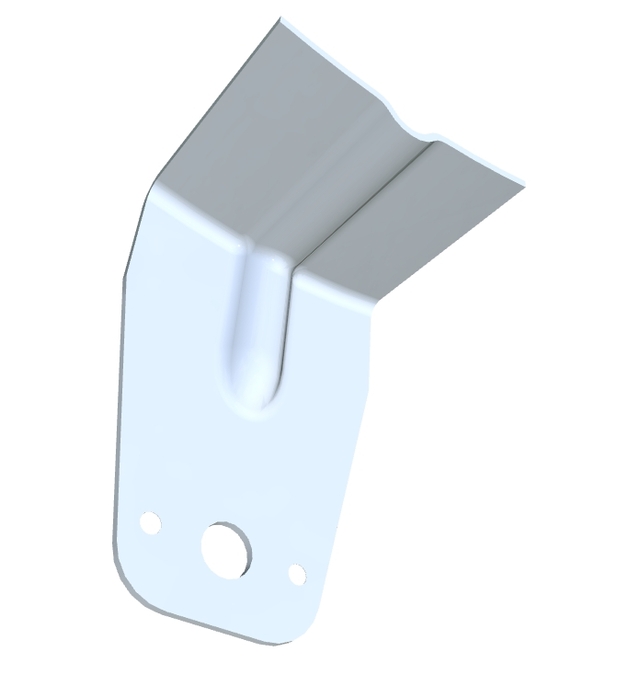

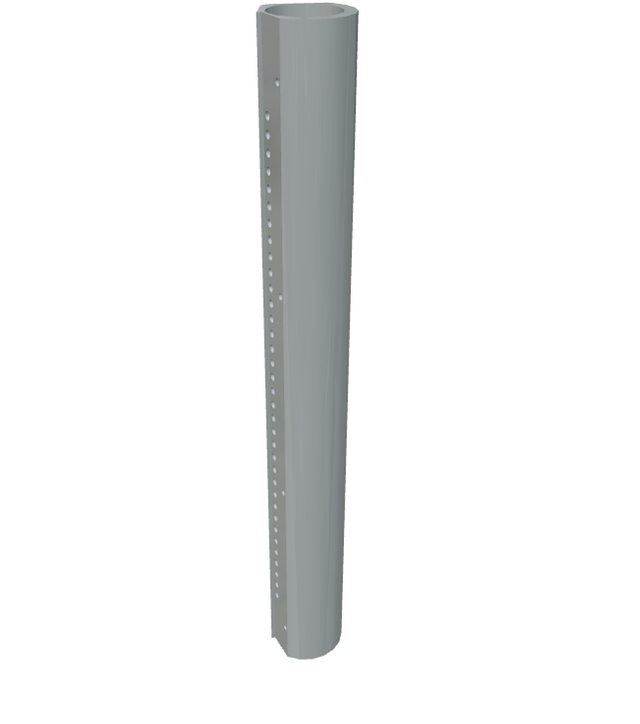

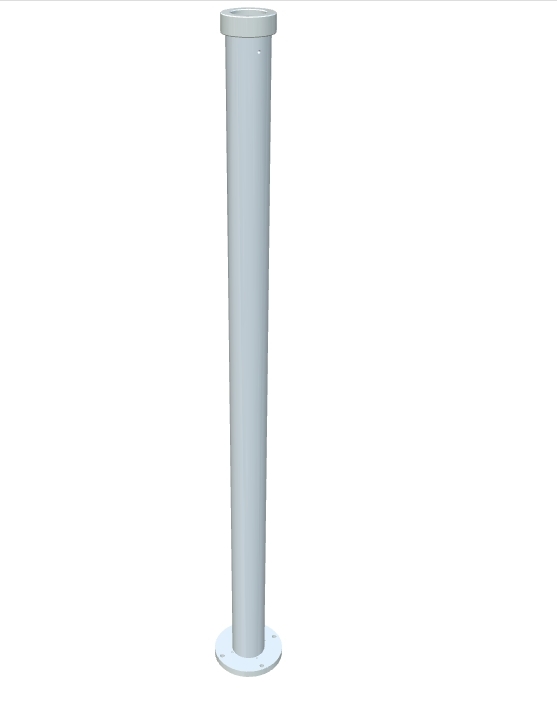

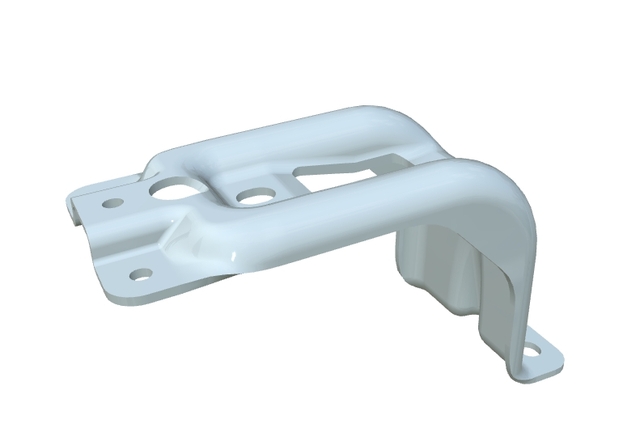

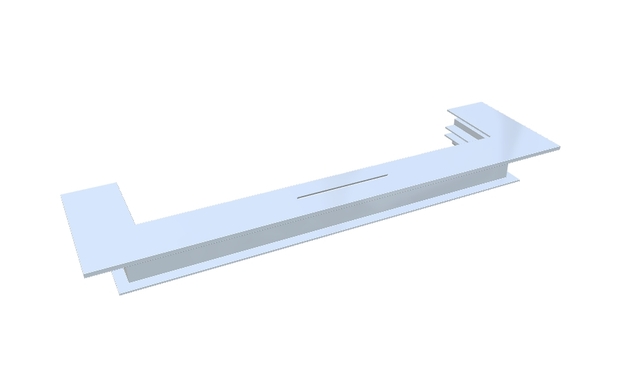

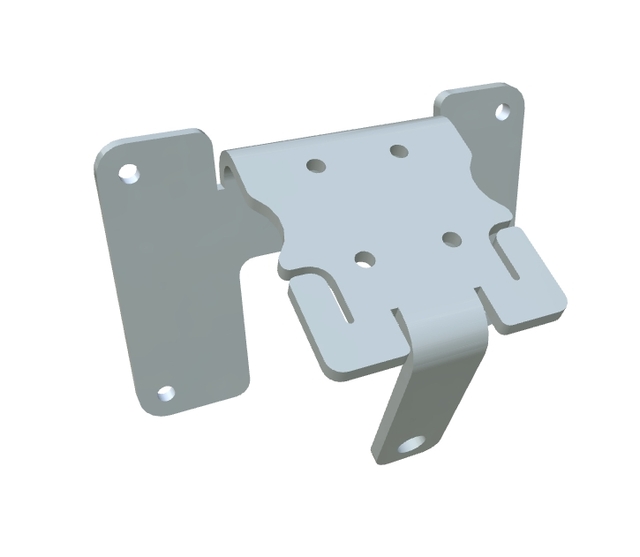

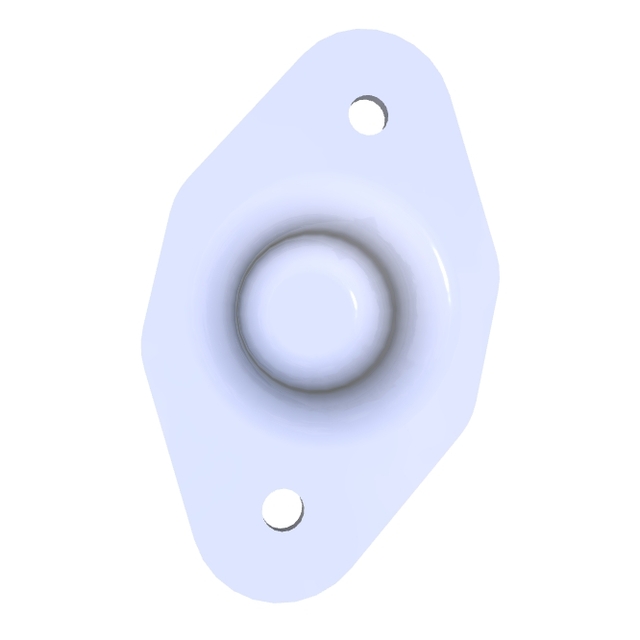

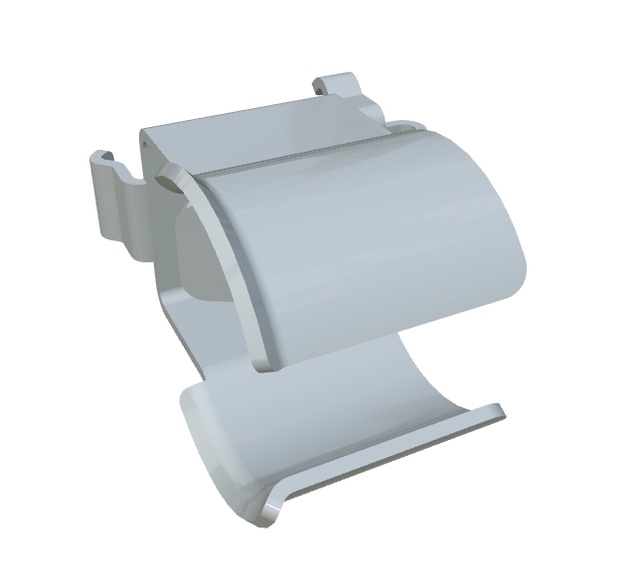

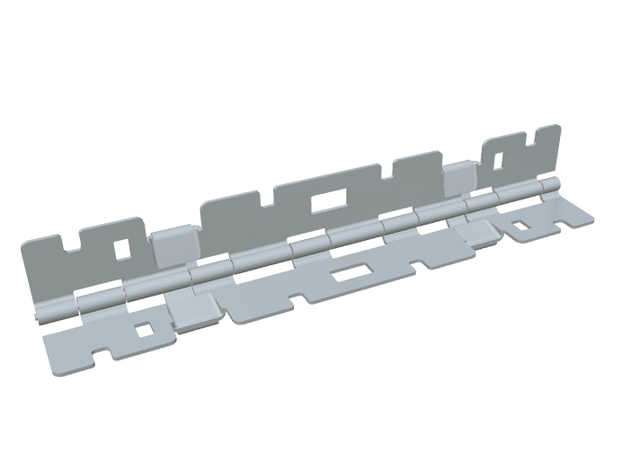

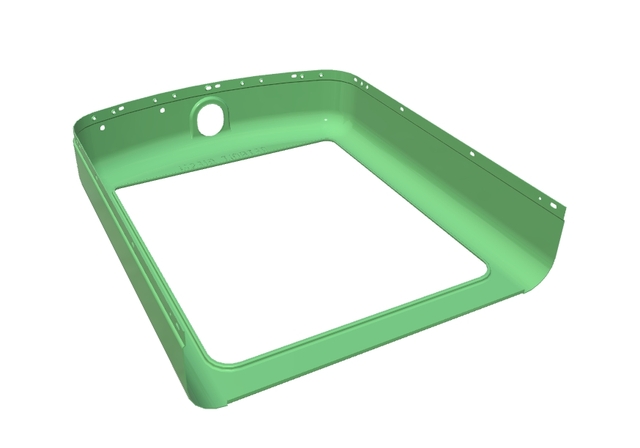

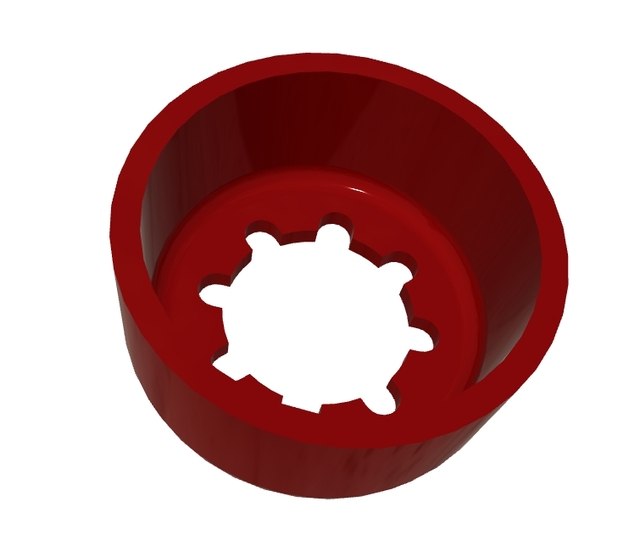

Sheet metal fabrication is not just about cutting and shaping metal; it's about transforming raw materials into functional, durable pieces that meet the stringent demands of today’s industrial applications. The Precision Stamped Metal Panel encapsulates this ethos. Designed with a reinforced cross pattern, this component not only enhances structural integrity but also adds a modern touch to any implementation. Whether you're dealing with HVAC systems, automotive assemblies, or architectural structures, this product offers unparalleled performance through its premium stainless steel construction, renowned for corrosion resistance and prolonged durability.

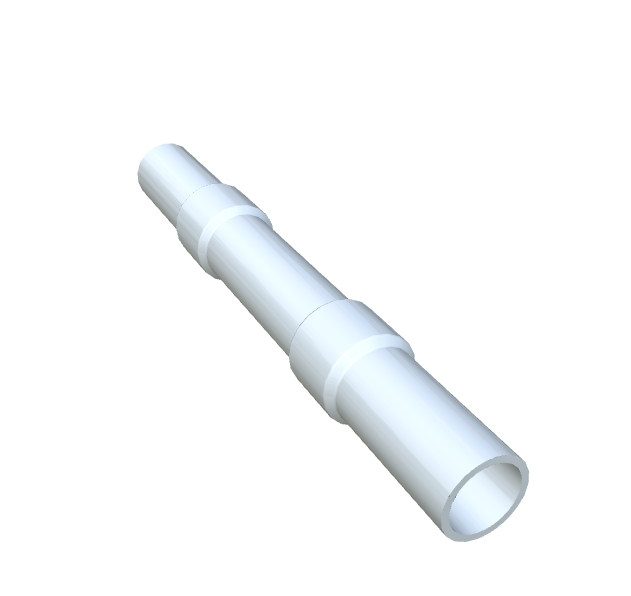

LS Hardware Tech Co., Ltd has set benchmarks in the field of metal fabrication services, utilizing cutting-edge CNC sheet metal fabrication techniques. Our expertise does not stop at producing high-quality aluminum or engaging in steel fabrication; it extends to offering comprehensive metal solutions to industries including automotive, aerospace, medical devices, and consumer electronics. The Precision Stamped Metal Panel is fabricated with dimensions and precision that accommodate effortless integration into existing systems, complete with multiple fastening holes designed for ease of installation.

The journey of LS Hardware Tech Co., Ltd started over two decades ago, led by Mr. Nick Zhang, an expert in engineering and manufacturing. What began as a vision has blossomed into a powerhouse in precision production. Our factory, a testament to modern engineering, hosts over 100 high-end machining centers. These facilities, coupled with our ISO 9001:2015 certification, ensure that every product that leaves our floor carries the hallmark of quality that our over 5,000 clients worldwide have come to expect.

As our company grows and technology evolves, our commitment to delivering superior quality remains unwavering. Our Precision Stamped Metal Panel is a testament to our mission to provide innovative, efficient solutions that empower our clients, helping them turn their boldest ideas into reality. For companies seeking reliable metal fabrication, LS Hardware Tech Co., Ltd offers a partner that not only meets but exceeds the high demands of a rapidly changing global market. By integrating sophisticated design with practical application, we continue to be a trusted name in innovative sheet metal solutions.

Incorporating custom sheet metal into your project has never been more straightforward or more beneficial. The Precision Stamped Metal Panel complements both functional and aesthetic components of any design, ensuring that projects are not only robust and reliable but also visually appealing. From prototypes to mass production, our services cater to every need, making seamless integration into systems a reality.

In conclusion, LS Hardware Tech Co., Ltd stands at the cutting edge of sheet metal design, offering products like the Precision Stamped Metal Panel that satisfy both aesthetic desires and performance requirements. With our proven track record in sheet metal fabrication, we are dedicated to pushing the boundaries of what is possible. As industries continue to grow and evolve, they require partners who are adept, agile, and equipped to meet their dynamic needs. At LS Hardware Tech Co., Ltd, we remain committed to driving innovation and excellence in all our endeavors.

Sheet Metal Fabrication: Precision Panels & Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Bending, Sheet Metal Fabrication, Laser Cutting, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

Dongguan City Longsheng Hardware Technology Co., Ltd

Dongguan City Longsheng Hardware Technology Co., LtdPeople who viewed this also viewed

Exploring the Hydroforming Process: Advantages & Applications

Mastering Stamping Techniques in Modern Manufacturing

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process: Precision in Metal Blanking

Mastering the Blanking Process in Metal Fabrication