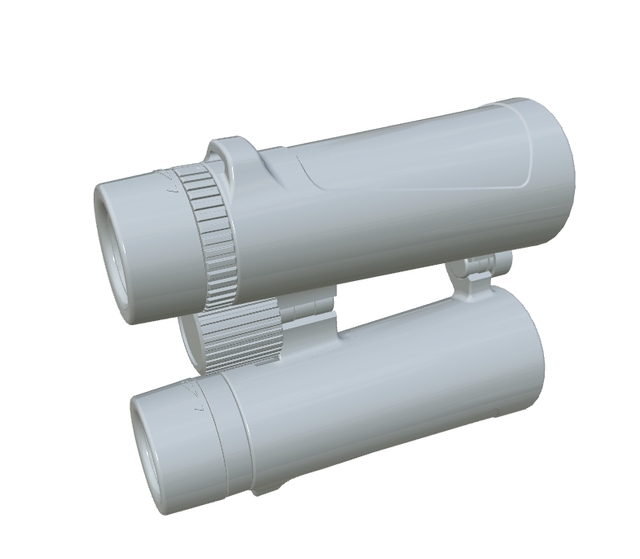

In the dynamic world of manufacturing, **injection molding** continues to be one of the most impactful processes for creating complex and durable parts. Known for its versatility and efficiency, injection molding is a preferred method for producing a wide range of components across various industries. Whether it’s automotive parts, consumer goods, or even custom-designed objects, this process plays a crucial role in shaping the industry.

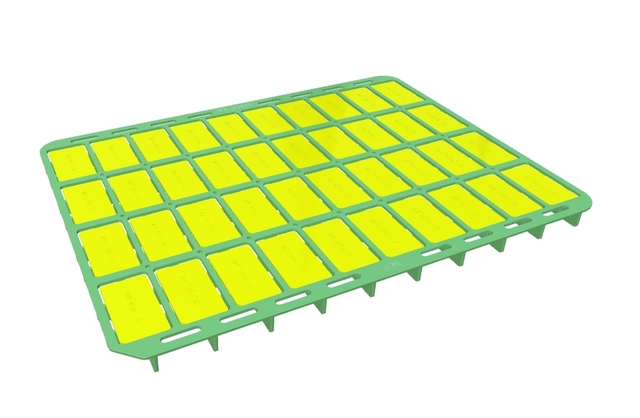

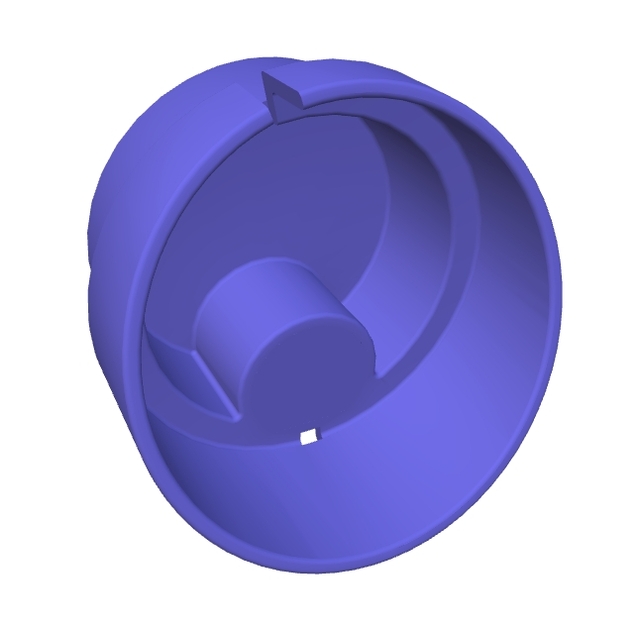

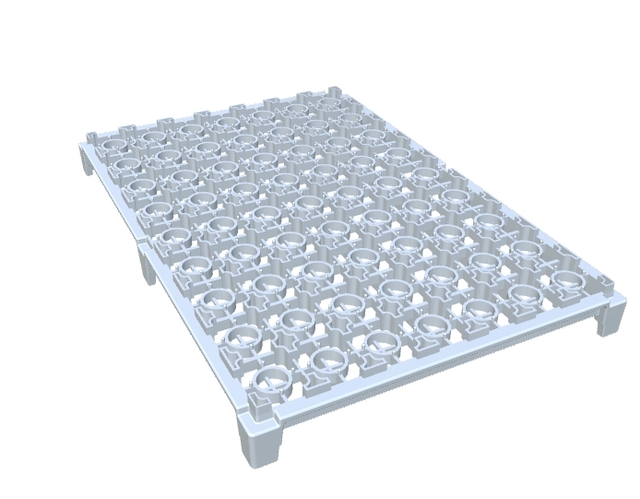

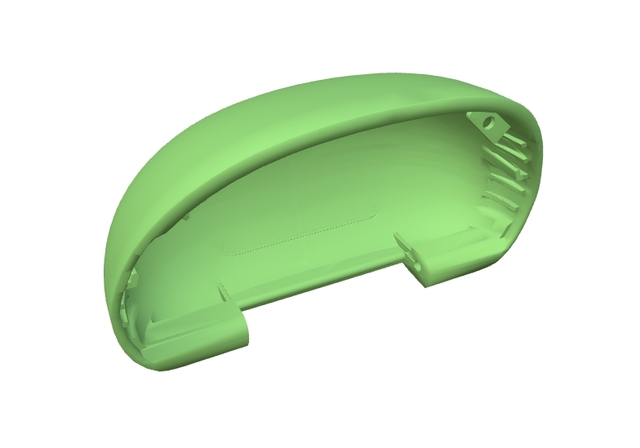

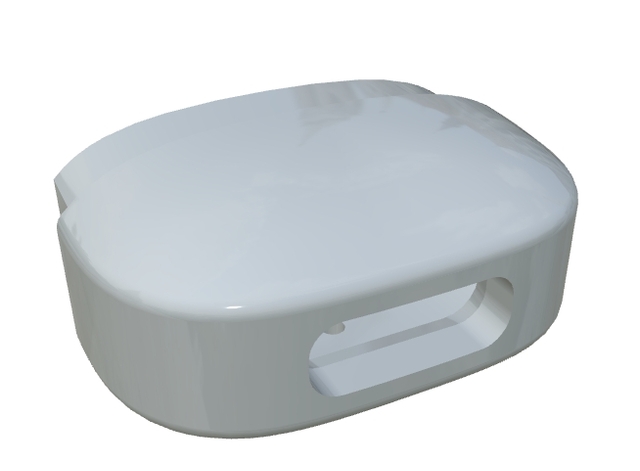

Understanding the **injection molding process** is pivotal for manufacturers aiming to leverage its benefits. The process involves injecting molten material into a mold, where it cools and solidifies into the desired shape. This method is favored for its ability to produce large volumes of identical items quickly and with great precision. Materials ranged across thermoplastics and thermosetting plastics are primarily used, making this technique highly adaptable to different product requirements.

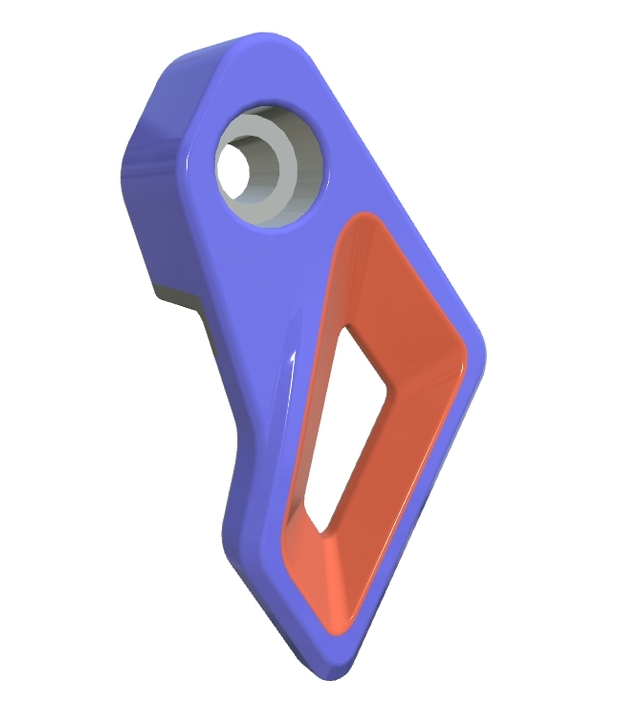

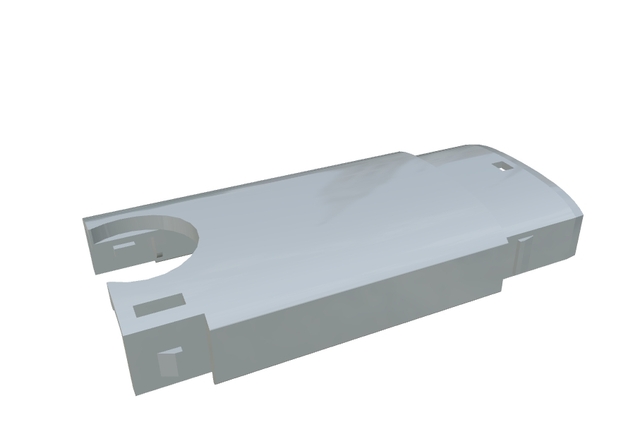

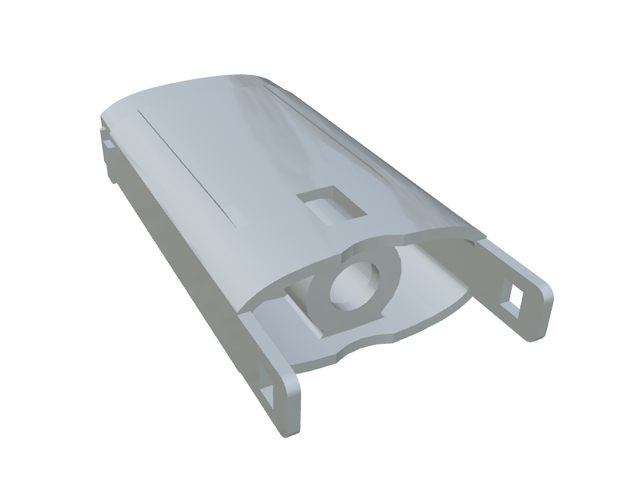

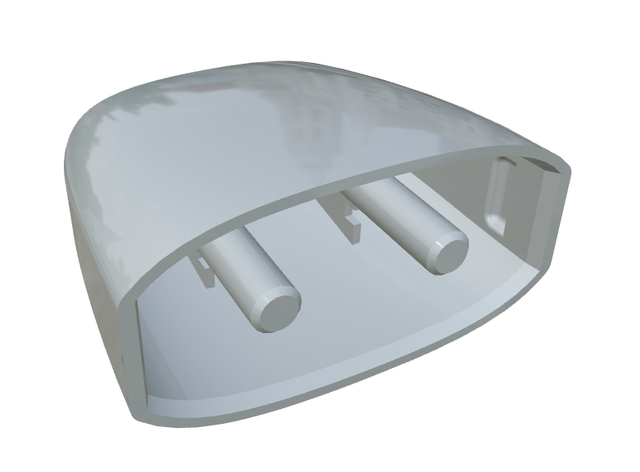

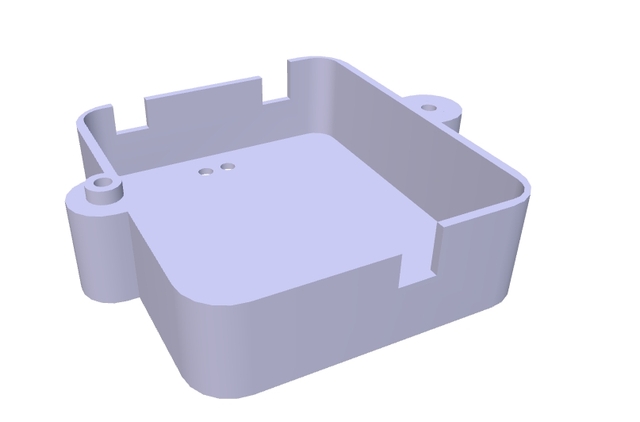

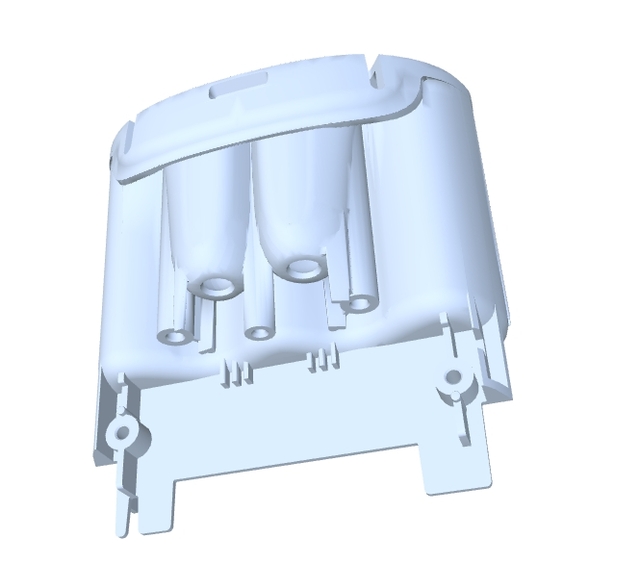

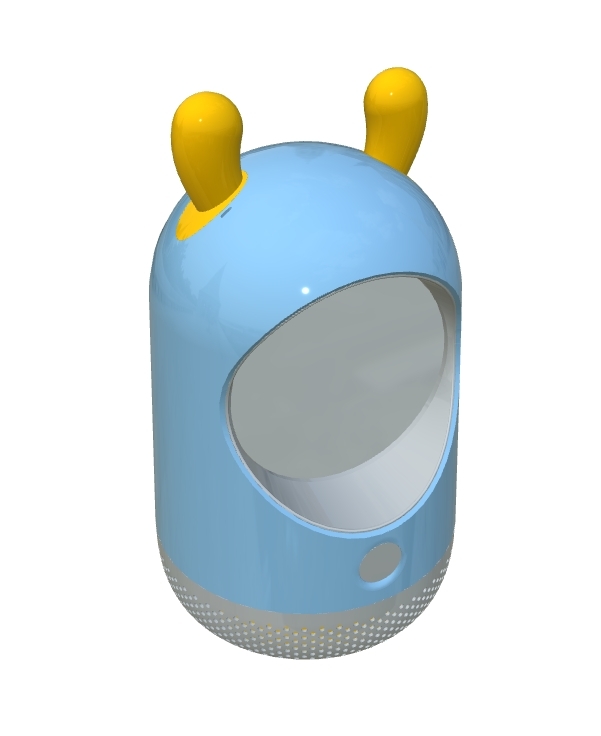

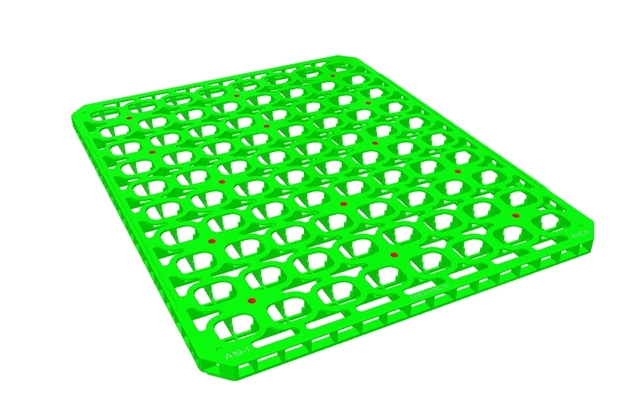

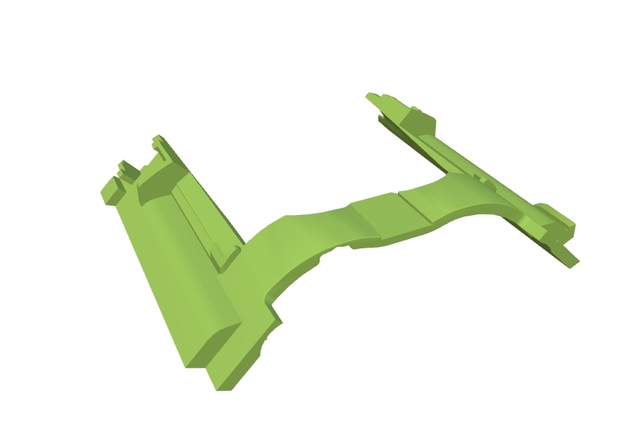

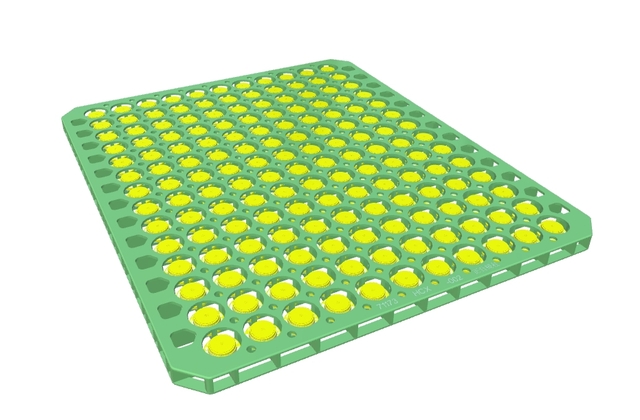

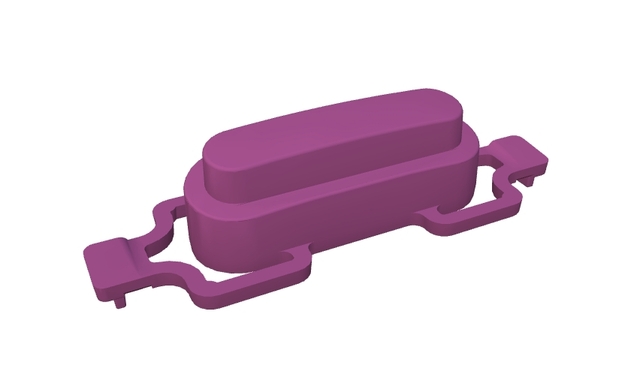

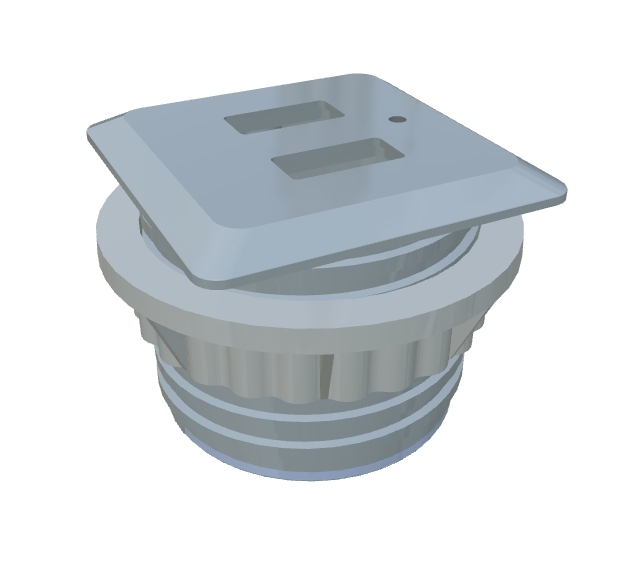

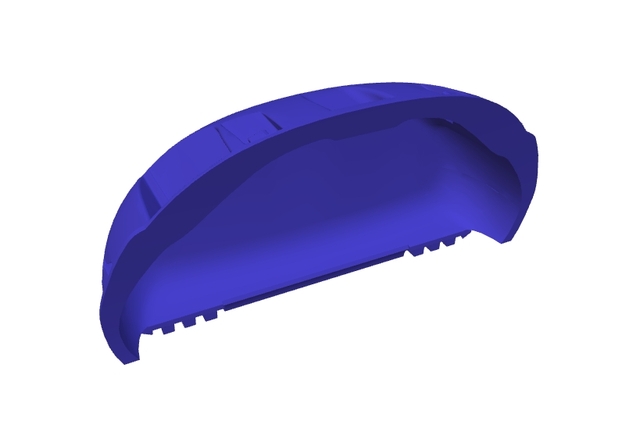

Advancements in **injection molding design** have further enhanced its applicability and efficiency. Custom injection molding allows for the creation of bespoke components tailored to specific applications or projects. This is particularly beneficial when working with complex shapes or when integrating various functionalities into a single part. In addition, by selecting the right **injection molding materials**, manufacturers can improve the quality, durability, and performance of their products. These materials are chosen based on factors such as strength, elasticity, thermal stability, and resistance to environmental factors.

At the heart of this process are the **injection molding machines**, which vary in type and size to accommodate different production needs. From simple machines for small batch runs to advanced models for large-scale production, these machines are integral to maintaining the efficiency and precision of the injection molding process.

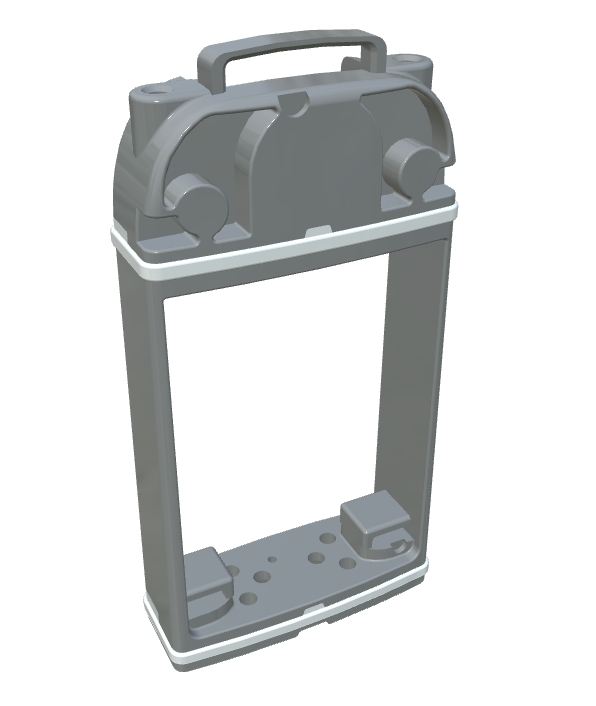

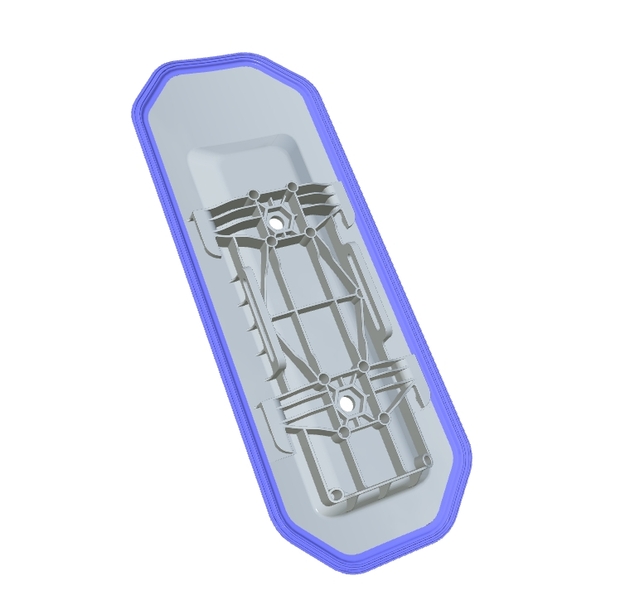

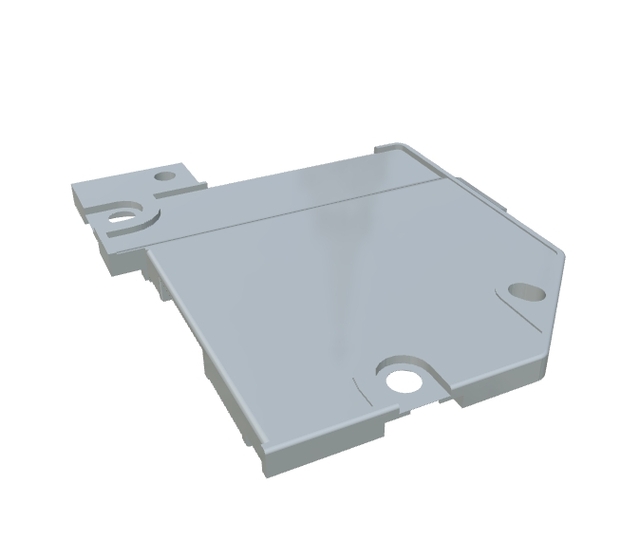

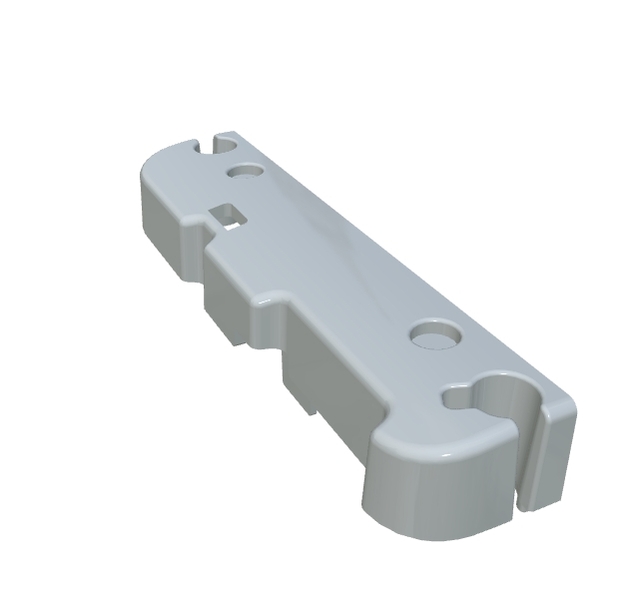

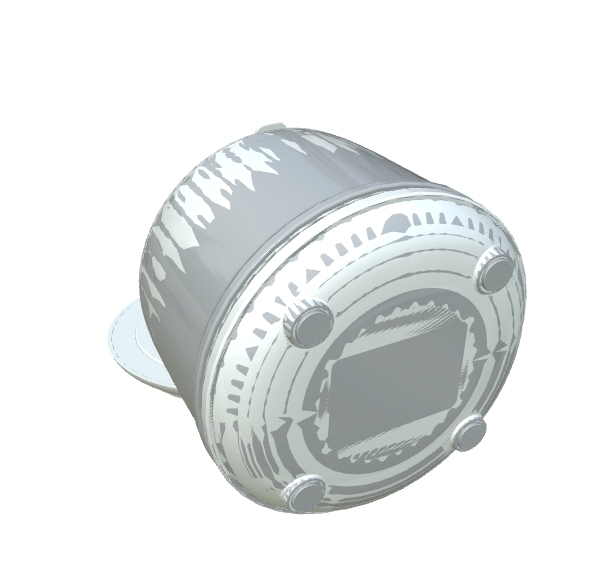

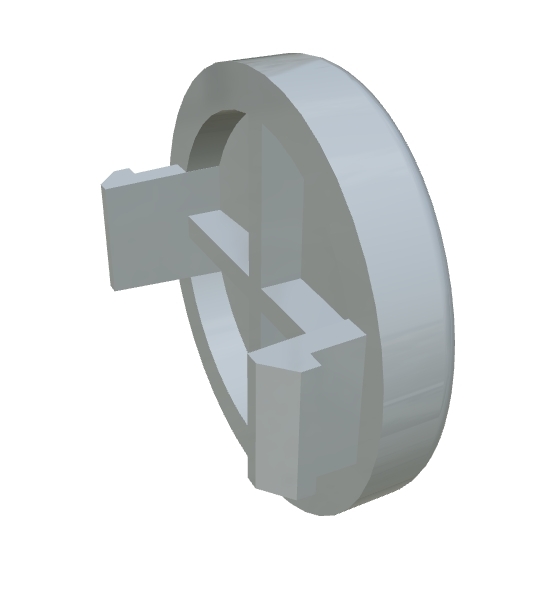

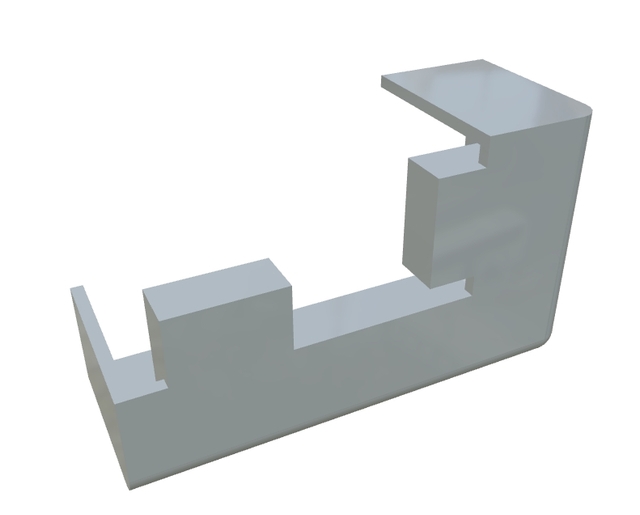

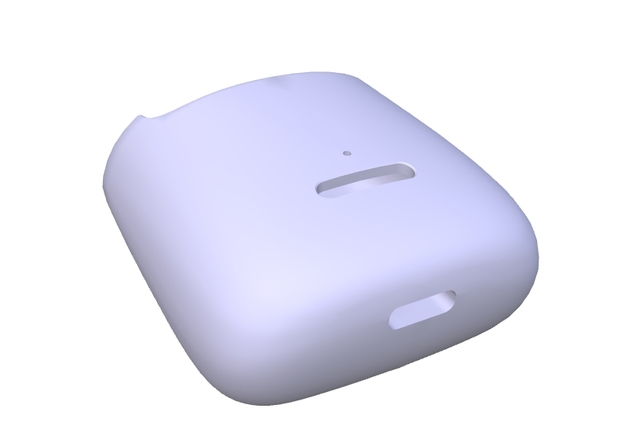

In line with these technological advancements, our latest product offering reflects the potential of this versatile technique. We are proud to present our sleek and robust metal bracket, designed for a multitude of applications. Whether it's for shelving support or structural reinforcement, this bracket showcases the innovative engineering that comes with meticulous design and manufacturing processes.

Crafted from high-quality metal, our bracket boasts a smooth, reflective surface that resists both corrosion and wear. Its minimalist design integrates seamlessly into any modern environment, offering not just functionality but also aesthetic appeal. The strategically placed holes in the bracket allow for precise screw fittings, ensuring ease of installation and maximum load-bearing capacity. This attention to detail ensures that our product will meet the demands of engineers, architects, and DIY enthusiasts seeking reliability and style.

In conclusion, **plastic injection molding** and its variants remain a cornerstone of efficient manufacturing, demanding precision and innovation. As more industries look to **injection molding suppliers** for solutions, the transformative power of injection molding will continue to drive product development forward, much like our new metal bracket exemplifies high-quality, versatile, and technologically advanced manufacturing.

Mastering Injection Molding Process: Design & Materials

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.