In the world of manufacturing and production, the process of plastic injection molding stands out for its efficiency and precision. With the ability to produce complex shapes and designs, plastic injection molding has become the backbone of modern industries. This transformative technique not only supports large-scale production but does so with the promise of high quality and consistency.

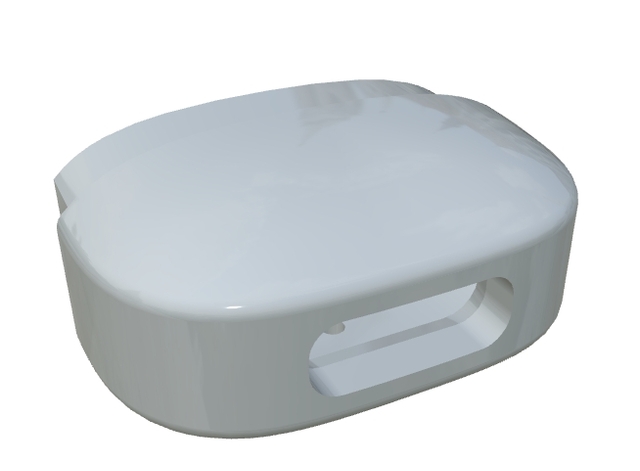

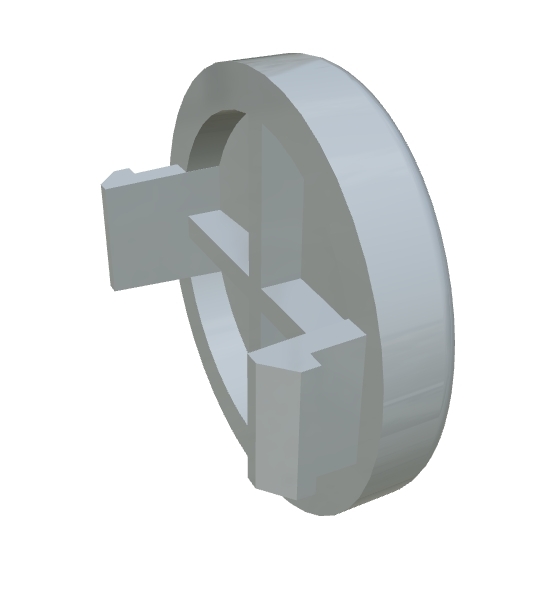

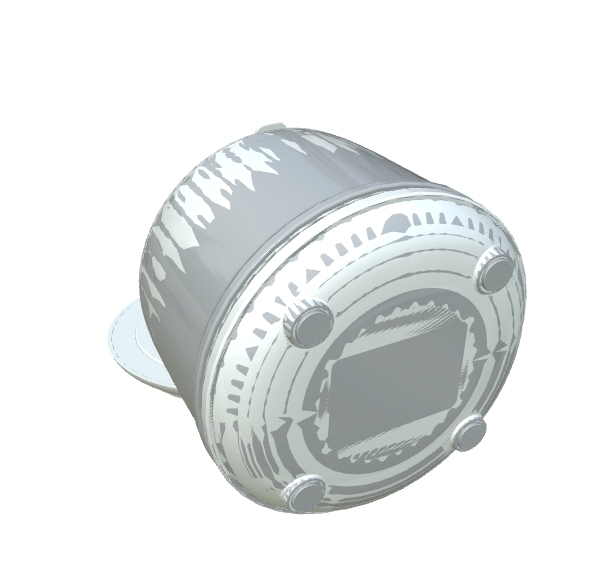

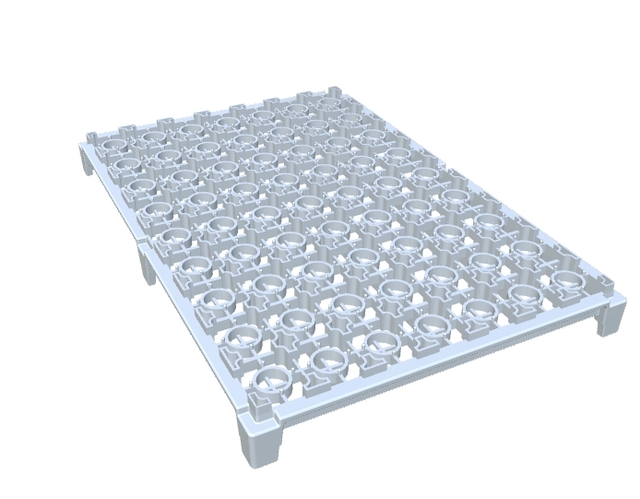

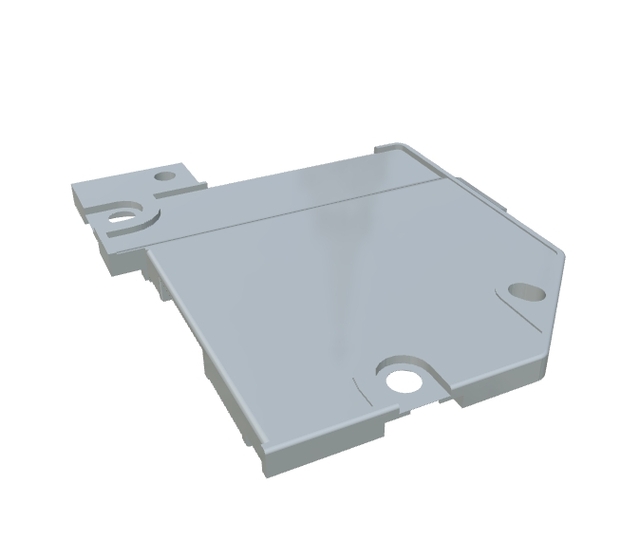

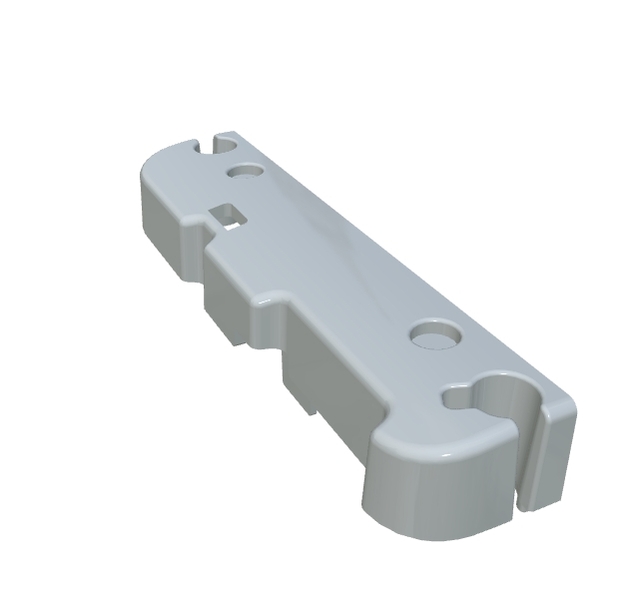

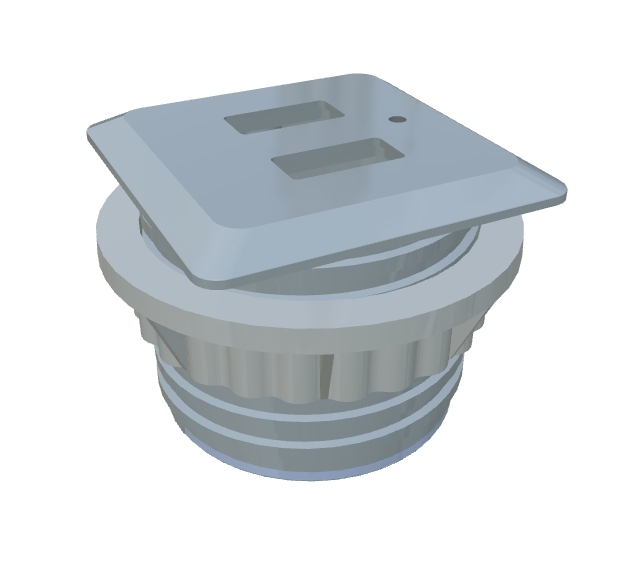

Plastic injection molding services have revolutionized the way products are designed and manufactured. From creating custom plastic molds to engineering intricate industrial plastic mold designs, these services offer endless possibilities. The development of injection molds manufacturing has paved the way for businesses to achieve highly detailed products that meet specific design criteria. This tailoring ability can be observed in recent innovations like our sleek and robust metal mounting plate. Though primarily constructed from metal, the role of plastic mold production in its ancillary components cannot be understated.

High quality injection molds are crucial as they ensure the reliability and durability of parts that go through the injection molding process. For example, utilizing rapid prototyping molds, businesses can quickly iterate designs, facilitating faster time-to-market with superior products. Injection molds provide the template needed to inject molten plastic, producing items that maintain uniformity in quality and appearance. This same precision and reliability is mirrored in our metal mounting plate. Its design, characterized by precision and thoughtful engineering, reflects the ethos of plastic injection molding's attention to detail and accuracy.

For those embarking on professional installations or ambitious DIY projects, custom plastic molds serve as the perfect solution for creating parts that require a personalized touch. Whether for industrial setups or home-based initiatives, the injection molding services cater to an array of projects, creating opportunities for innovative applications. These molds, when combined with our durable mounting plates, ensure a secure and stable foundation for any assembly, promising strength and elegance in one breathtaking design.

In conclusion, leveraging the power of plastic injection molding and its related technologies can elevate manufacturing outcomes significantly. From enhancing product performance with durable materials to offering customized solutions with intricate mold designs, it's clear that the opportunities are endless. Our metal mounting plate stands as testament to these advancements, embracing them to deliver exceptional strength, longevity, and sleek aesthetics in whatever application it graces.

Plastic Injection Molding in Industrial Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.