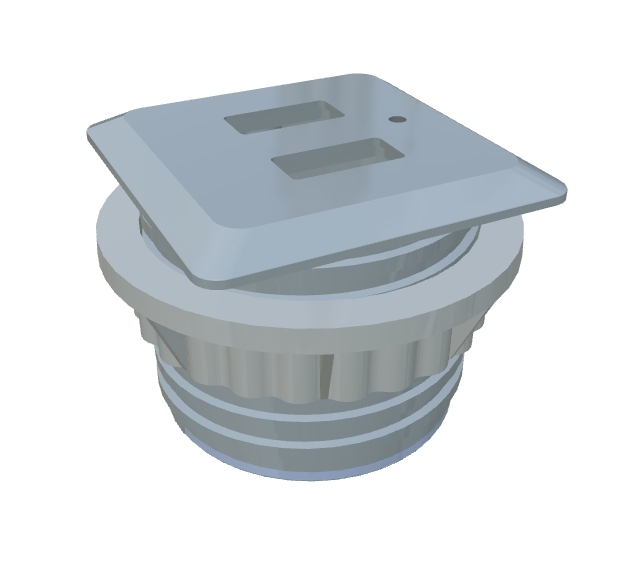

Plastic injection molding is an innovative and efficient process used in the production of everyday items, including the state-of-the-art Wall-Mount Bracket. As a leading method for generating high-quality plastic components, plastic injection mold manufacturers employ this versatile technology to create custom plastic molds for a wide range of applications.

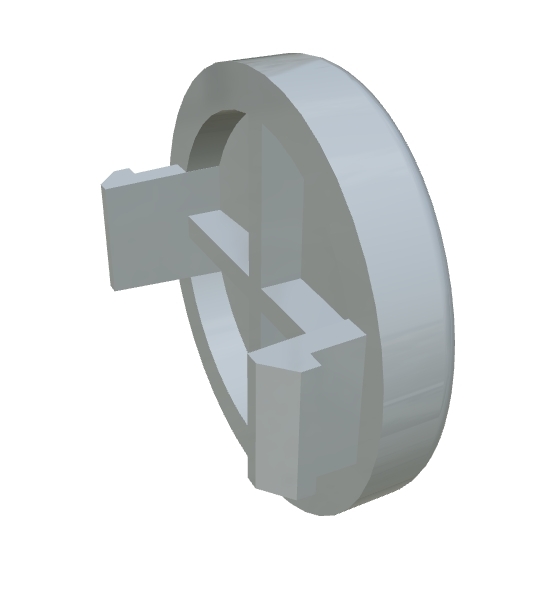

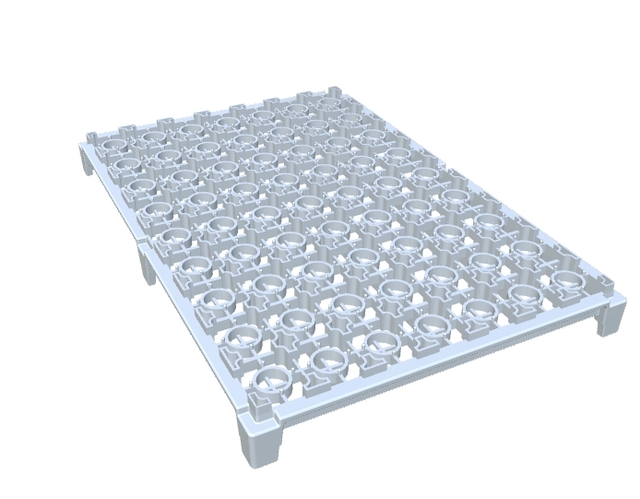

The injection molding process begins with designing injection molds that form the basis for mass production. High precision injection molds are crafted to enhance accuracy and ensure the highest quality output. This approach is particularly essential in applications involving industrial plastic molds because of the demanding environments and heavy-duty requirements. Utilizing thermoplastic injection molding, manufacturers can produce components that boast durability and flexibility, such as our stylish Wall-Mount Bracket.

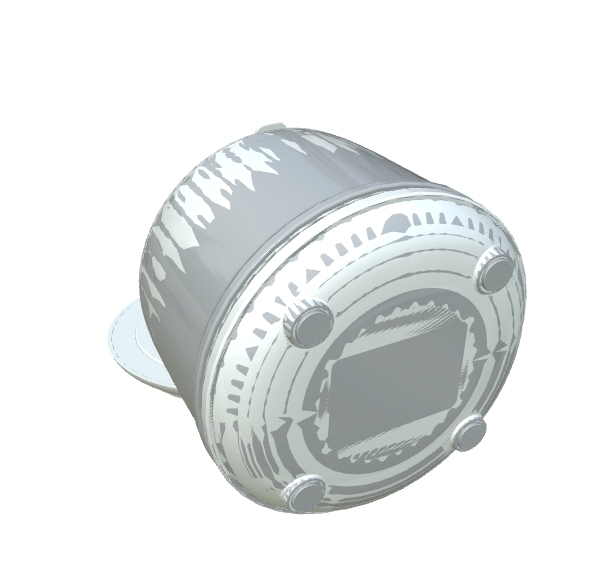

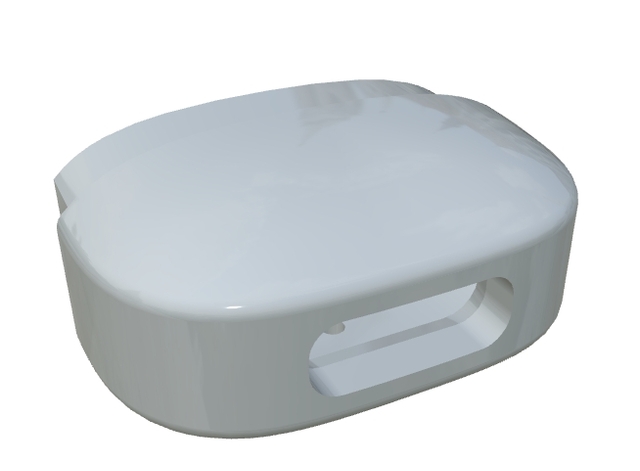

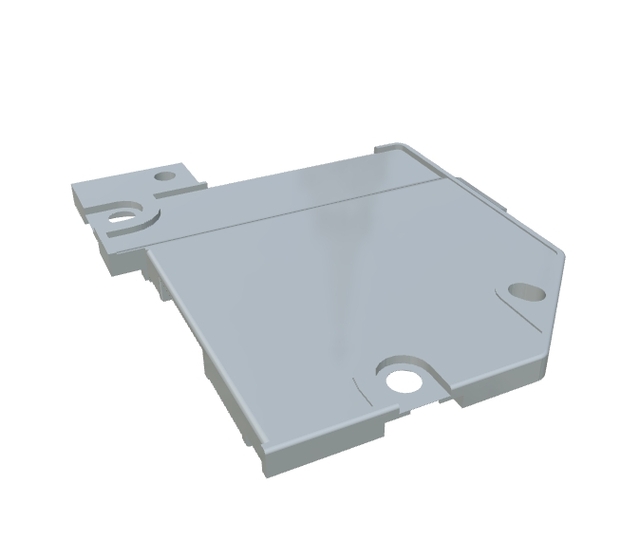

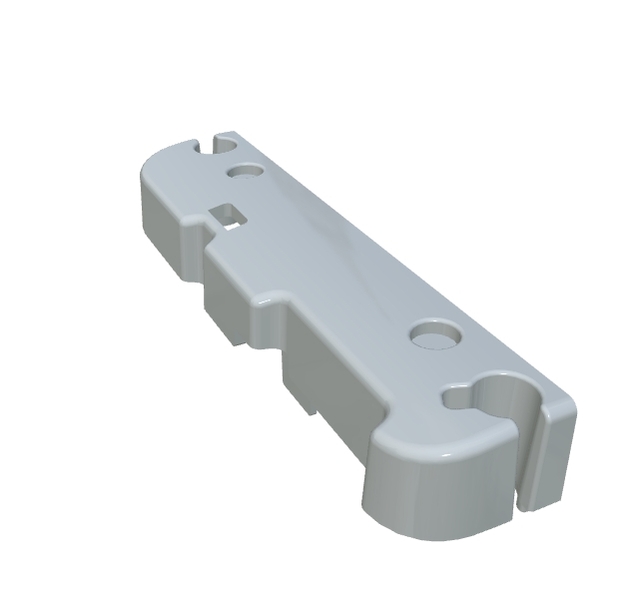

Designed specifically for both residential and commercial installations, the Wall-Mount Bracket is crafted from high-quality plastic, ensuring that it contributes to a sleek and modern decor. The bracket's surface retains a smooth, glossy finish, providing a polished look that blends in seamlessly with any color scheme or design. Thanks to the flexibility of the custom plastic molds, the bracket features multiple pre-drilled holes that offer ease of installation and adaptability across different settings, whether mounting shelves or other structures.

Plastic injection molding not only supports efficient production through injection mold design but also maximizes the load-bearing capabilities of products like the Wall-Mount Bracket. The injection molding process makes it possible for our wall mount bracket to maintain compactness and efficiency without compromising strength. This balance is achieved by optimizing the industrial plastic molds stage, ensuring the bracket upholds a high capacity for weight, proving both stylish and practical for all of your organizing needs.

For industries relying on high precision injection molds, thermoplastic injection molding represents a key technological advantage. The Wall-Mount Bracket exemplifies how these advancements in precision and the injection molding process as a whole furnish products with superior quality and versatility, offering customers reliable solutions tailored to both aesthetic and functional demands.

Plastic Injection Molding: Revolutionizing Custom Plastic Molds

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Plastic Injection Molds: The Future of High Precision and Sustainable Manufacturing

Plastic Injection Molds: Crafting Futuristic Products with Precision

Revolutionizing Manufacturing: The Power of Plastic Injection Molds

Plastic Injection Mold Design for High-Precision Pallets

Plastic Injection Molding in Industrial Design

Plastic Injection Molding: Revolutionizing Custom Plastic Molds

The Essential Guide to Plastic Injection Molds

Plastic Injection Molds: Revolutionizing Manufacturing