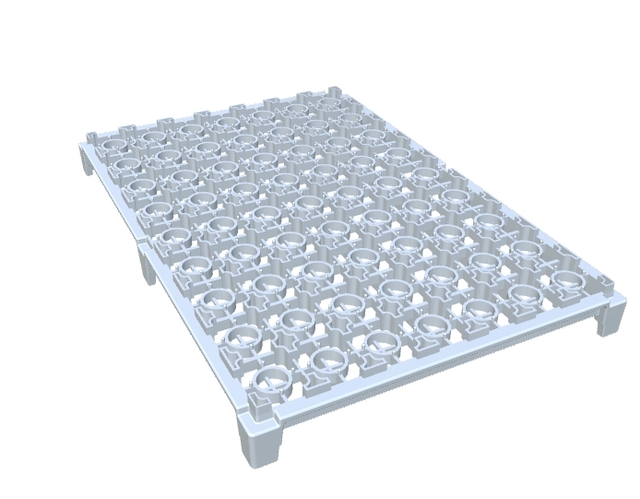

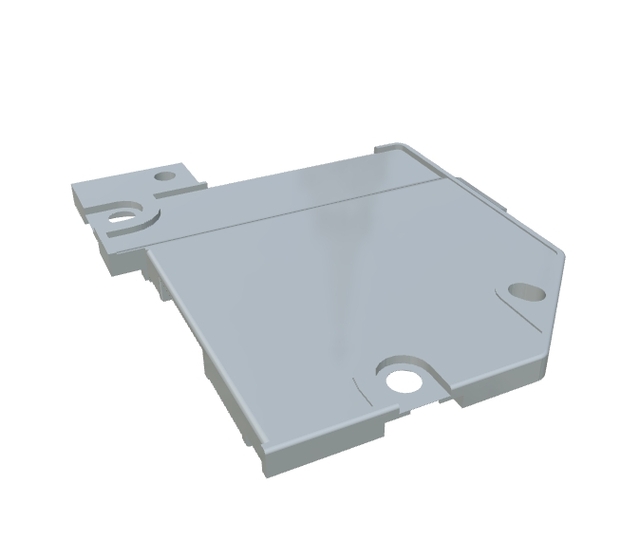

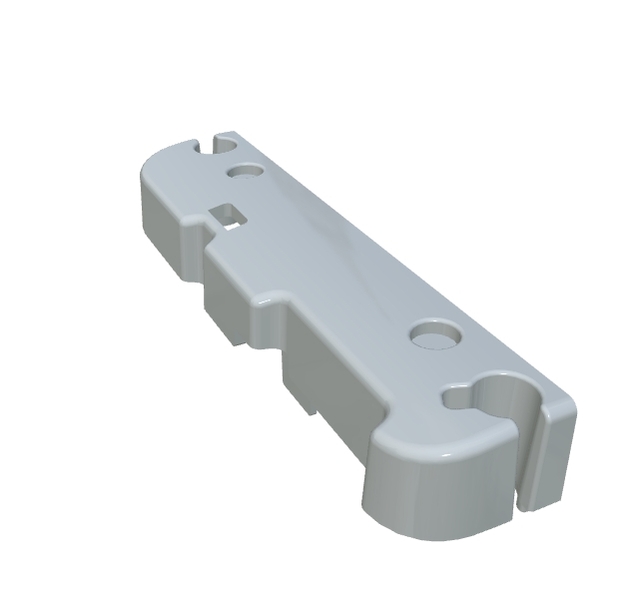

Plastic injection molds have revolutionized the manufacturing industry by allowing for the efficient production of complex parts with high precision and repeatability. These molds are the cornerstone of custom plastic injection molding processes, making them indispensable to manufacturers seeking quality and consistency. The versatility of injection mold design means that they can be adapted to various industries, from electronics to automotive parts, by utilizing robust plastic mold manufacturing methodologies.

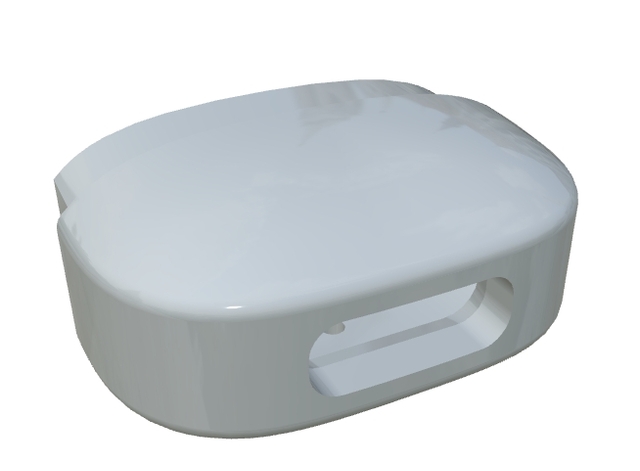

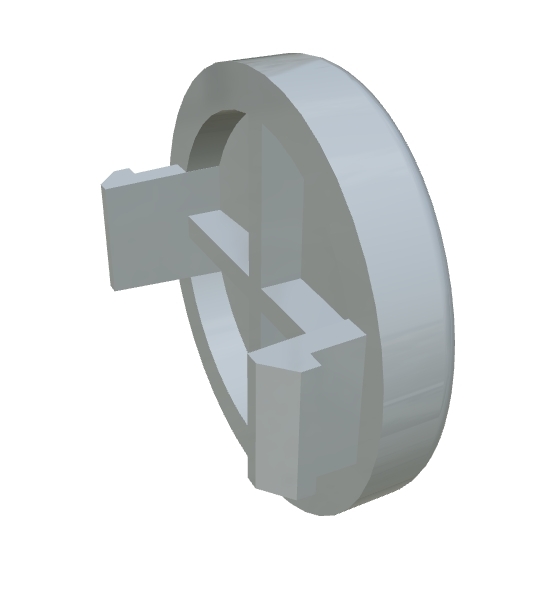

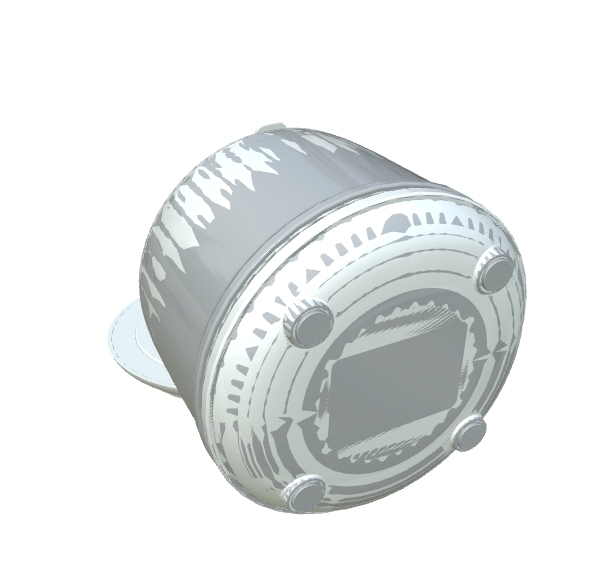

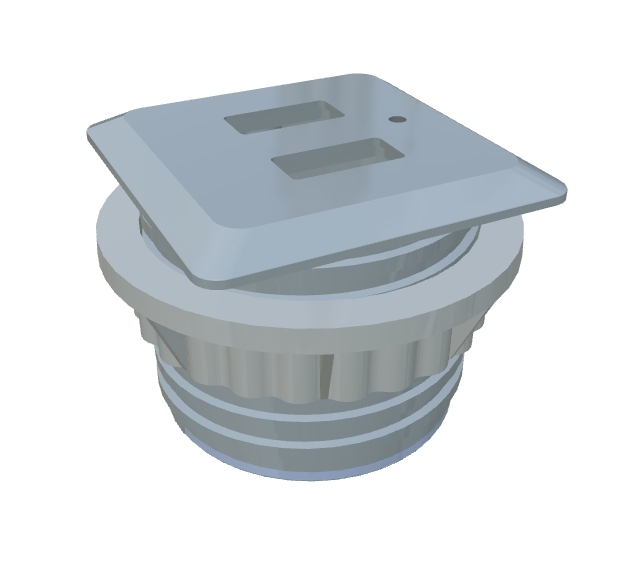

High precision injection molds facilitate the creation of intricate designs while maintaining tight tolerances, ensuring parts meet exact specifications. This level of precision is crucial for plastic injection mold makers who strive to deliver superior products to meet diverse client needs. One example of their extraordinary adaptability can be seen in the development of the innovative coffee pod. Designed for coffee aficionados, this product combines elegance with practical application, demonstrating the prowess of injection mold design in producing aesthetically pleasing and functional items.

Injection molding services play a pivotal role in helping businesses transition from design to full-scale production. With rapid prototyping injection molds, businesses can move swiftly through the design cycle, testing and refining their products before entering the mass production phase. Such services are crucial for the sustainability of competitive industries, ensuring that new products not only meet market standards but also embrace eco-friendly principles. For instance, the environmentally mindful coffee pod exemplifies how injection molds today are tailored to produce market-ready solutions that prioritize sustainability without compromising on quality or performance.

The integration of sophisticated sealing technology within these products is yet another benefit derived from precise plastic injection molds, maintaining the integrity and flavor of coffee pods. As consumers demand more from their products, plastic injection mold makers continually innovate, closely aligning with current trends in sustainable production and design optimization. The use of these molds in making compact and recyclable coffee pods is a testament to how far injection molding services have come in enhancing both consumer experience and environmental responsibility.

Overall, the development and application of plastic injection molds extend beyond traditional manufacturing paradigms, positioning businesses to meet both modern demands and sustainable practices. From the custom production of high-precision parts to the creation of eco-friendly consumer products like coffee pods, the continuing evolution of injection mold technology showcases the intersection of engineering excellence and responsible manufacturing practices. This synergy ensures that modern products are not just competitive but are also aligned with the ethos of a sustainable future.

Plastic Injection Molds: The Future of High Precision and Sustainable Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.