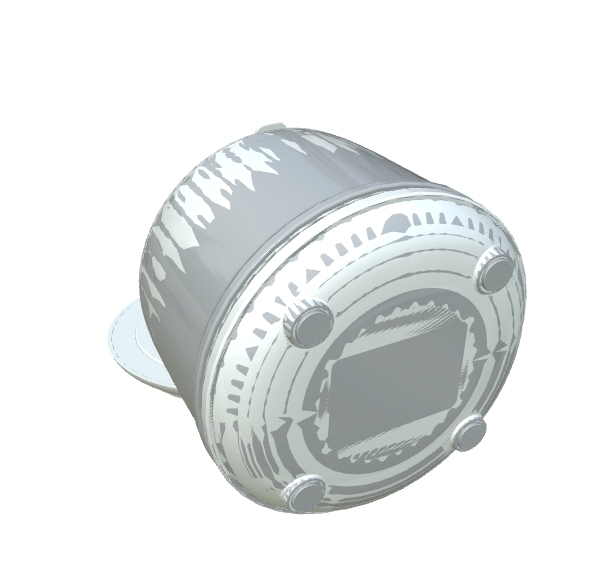

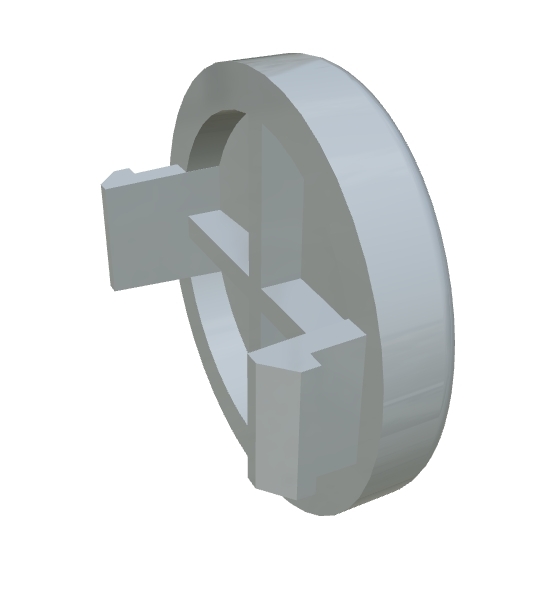

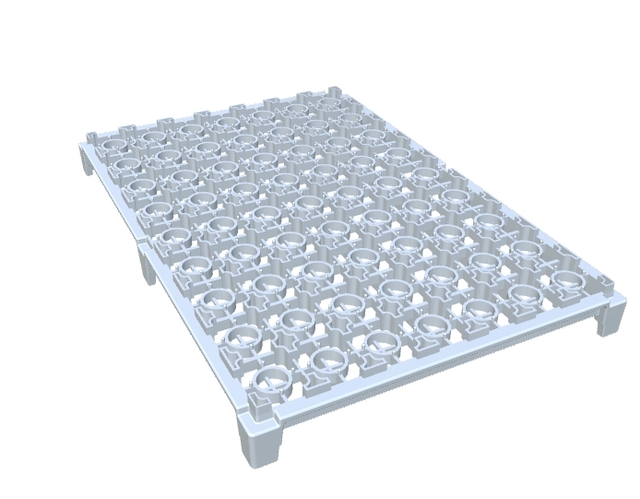

Plastic injection molds are a vital component in the world of manufacturing, providing solutions for a variety of industries. These tools are essential in the plastic injection molding process, where they are used to shape molten plastic into specific forms and sizes. Whether in electronics, automotive, or home goods, plastic injection molds allow manufacturers to create durable and precise plastic parts repeatedly.

Custom injection molds are particularly advantageous when it comes to producing unique and specialized components. They offer flexibility and precision that standard molds may not. Expert mold design services are often engaged to create these custom molds, ensuring they meet the exact specifications required by clients. This personalized approach enhances the quality of plastic parts manufacturing, boosting the efficiency and functionality of the final product.

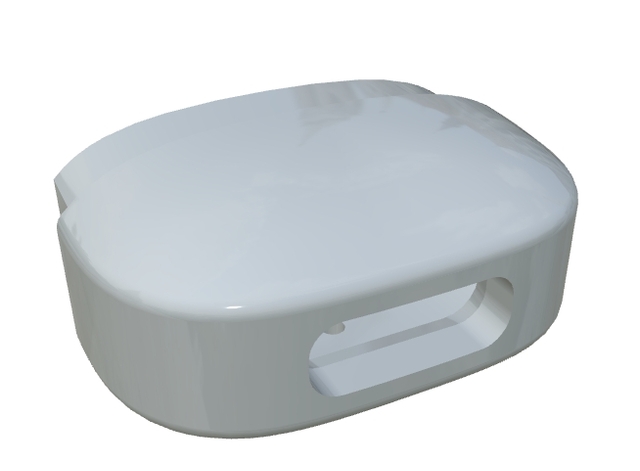

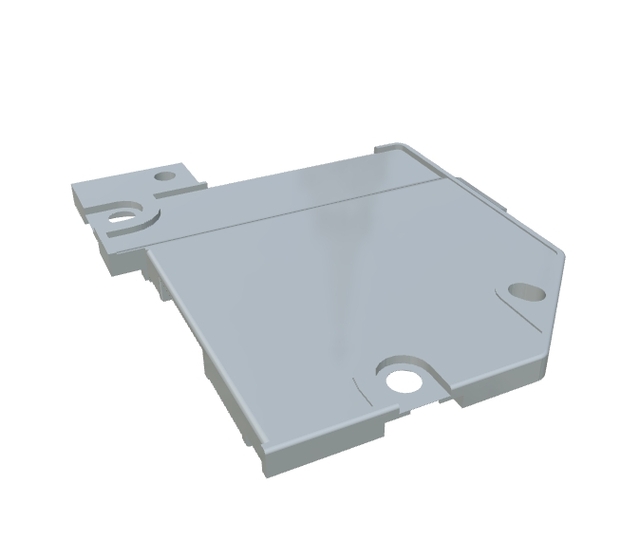

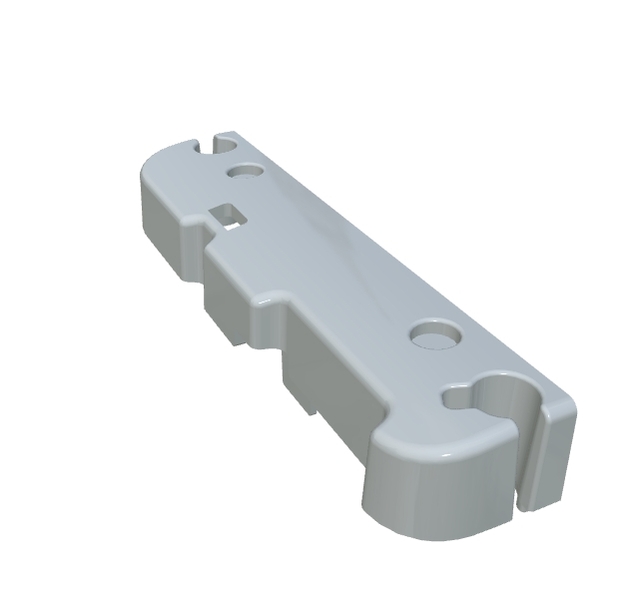

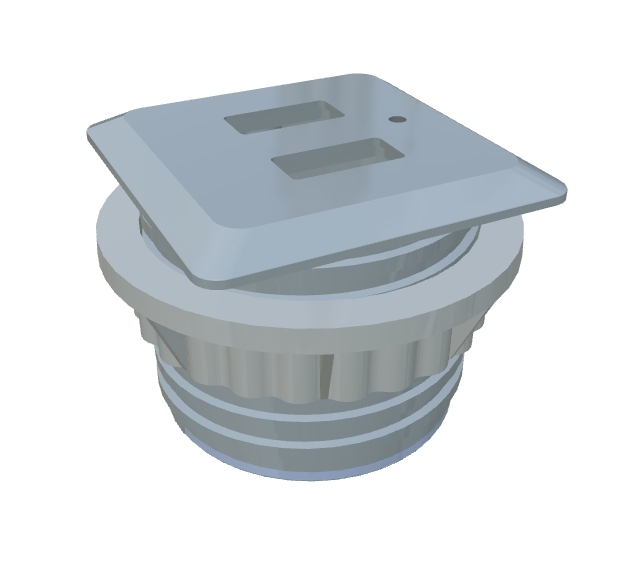

One significant aspect of plastic mold manufacturing is its ability to improve workspace solutions, such as the modern in-desk power module. This innovative device, designed for seamless integration into any work surface, exemplifies the advancements in plastic injection molding services. The module includes two standard AC power outlets and a USB-C port, catering to the modern tech demands and ensuring that essential electronic devices remain charged and functional. Its sleek, minimalist design with a chic metallic finish not only provides functionality but also elevates the aesthetic of any home or office workstation.

Injection molding services and rapid prototyping molds are instrumental in bringing such sophisticated products to life. These services allow manufacturers to create prototypes quickly, facilitating the transition from design to production. This efficiency is crucial in today’s fast-paced market, where consumer demands are continuously evolving. By leveraging advanced mold design and manufacturing techniques, companies can stay ahead of the curve, delivering products that meet the highest standards of quality and design.

In conclusion, plastic injection molds and related services play an essential role in modern manufacturing, especially for electronics and workspace solutions. The combination of precise mold design services and the latest injection molding technology ensures that products like the in-desk power module not only meet but exceed user expectations in functionality and style. As technology advances, the importance of efficient and innovative plastic mold manufacturing will only continue to grow, shaping the future of product design and functionality.

Plastic Injection Molds: Revolutionizing Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Plastic Injection Molds: The Future of High Precision and Sustainable Manufacturing

Plastic Injection Molds: Crafting Futuristic Products with Precision

Revolutionizing Manufacturing: The Power of Plastic Injection Molds

Plastic Injection Mold Design for High-Precision Pallets

Plastic Injection Molding in Industrial Design

Plastic Injection Molding: Revolutionizing Custom Plastic Molds

The Essential Guide to Plastic Injection Molds

Plastic Injection Molds: Revolutionizing Manufacturing