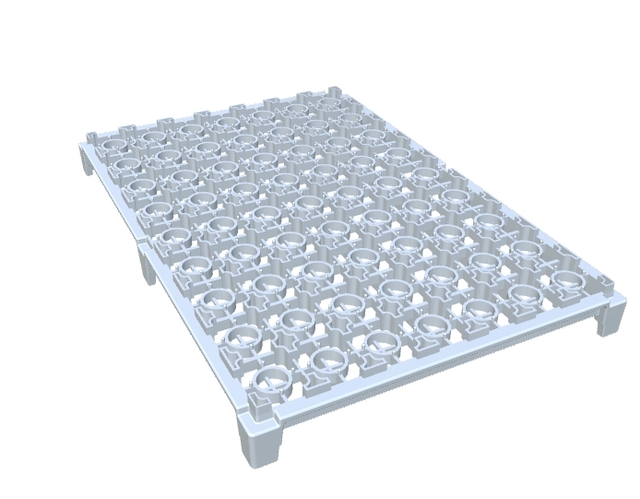

The production of **plastic injection molds** is a cornerstone of modern manufacturing, allowing for the efficient and cost-effective production of plastic components essential in various industries. With the main function of shaping plastic into desired forms, these molds are indispensable in creating a variety of products, from simple plastic containers to intricate parts used in electronics and automotive industries.

One of the key advantages of using custom plastic molds is their ability to precisely produce detailed components at a high volume, making them crucial for companies needing consistent quality in their products. **Custom plastic molds** offer tailored solutions that meet specific design requirements, essential for businesses aiming for precision, such as those in the electronics world where exact fitting and reliable performance is paramount. **High-quality injection molds** ensure that each component or product is manufactured to the exact specifications, thereby reducing waste and increasing production efficiency.

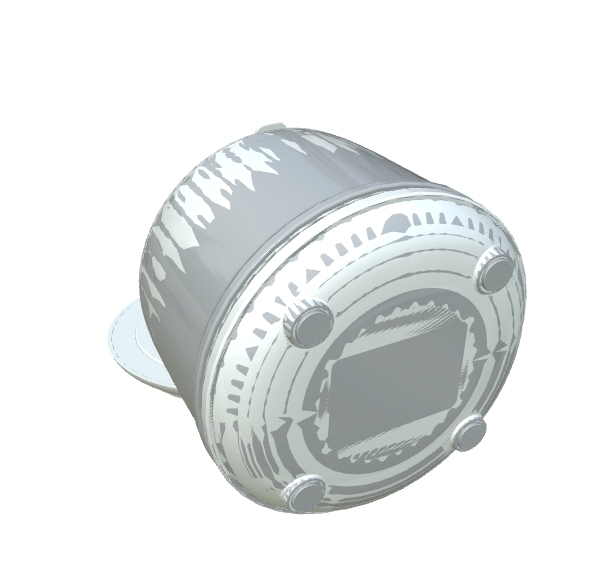

The **injection molding process** itself is a marvel of modern engineering. It involves feeding plastic pellets into a heated barrel, melting them, and injecting the molten plastic into molds where it cools and hardens into the final shape. This process is fast and can produce hundreds of thousands of parts with a single mold, making it incredibly efficient for mass production requirements.

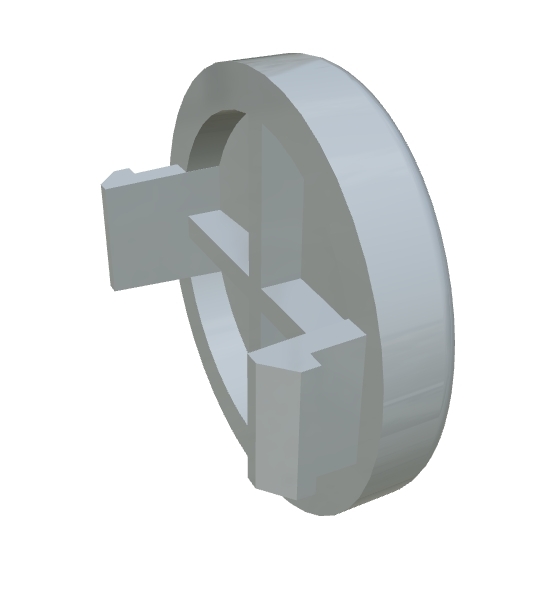

**Plastic mold manufacturers** work closely with clients to design and develop molds that meet both aesthetic and functional goals. They provide comprehensive **mold design services**, ensuring that every aspect of the product aligns with the client's vision and operational needs. These services are part of what makes **injection molding companies** invaluable partners in industries ranging from consumer electronics to medical devices.

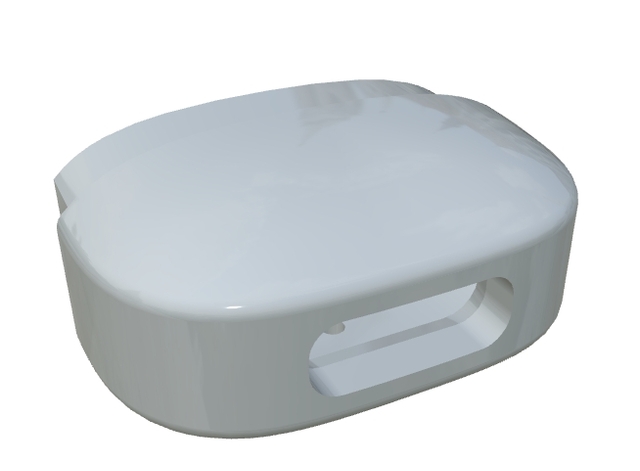

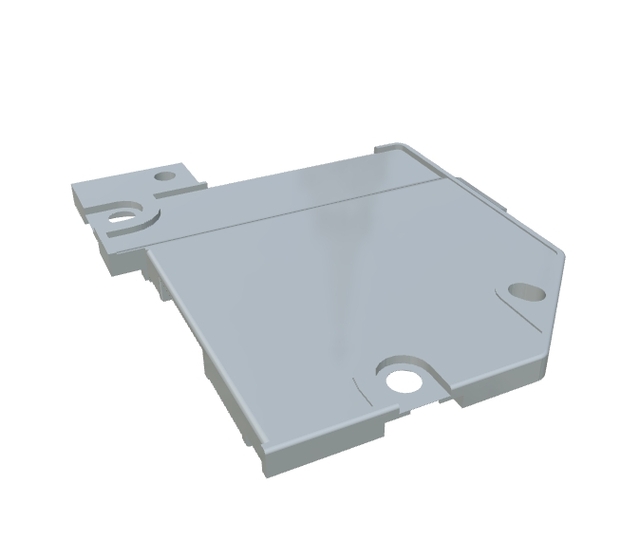

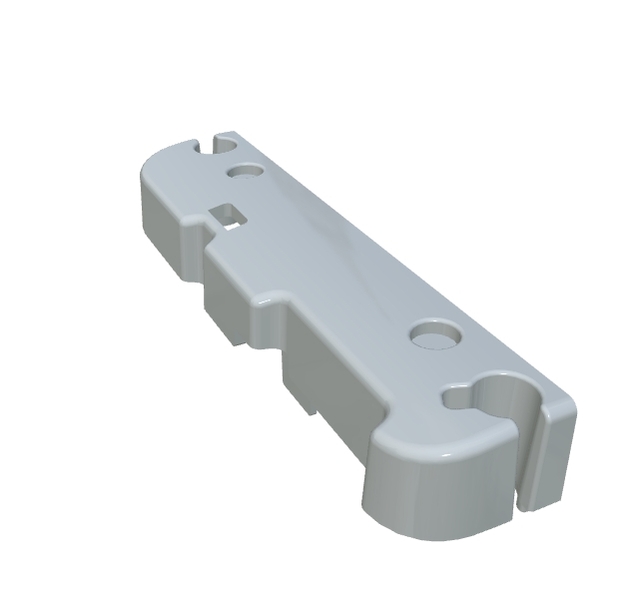

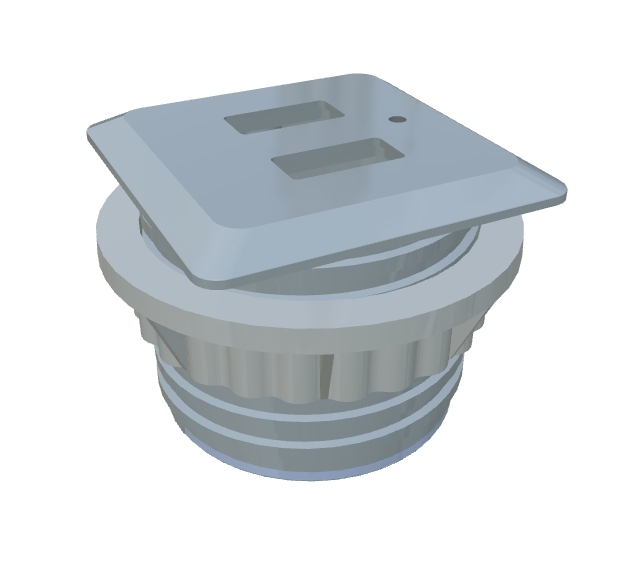

Take for example, the innovative Pop-Up USB Charger, a sleek and modern device that integrates seamlessly into workspaces and home environments. This product showcases the perfect application of plastic injection molding, with its low-profile lid and multiple USB ports providing efficient, clutter-free charging. It highlights how such techniques allow for elegant, minimalistic designs complemented by robust functionality. The design ensures not only a stylish appearance but also ease of installation, making powerful technology accessible to all.

In today's fast-paced technological landscape, products like the Pop-Up USB Charger are essential, offering practical and stylish solutions to power needs. The compact form and reliable performance are resultant from effective plastic parts production enabled by expert mold manufacturers. Through the use of high-quality designs, reliable injection molding, and precise manufacturing processes, modern products can maintain their competitive edge while satisfying customer demands.