The **overmolding process** is a transformative technology that has redefined the scope of manufacturing and product design. It involves the technique of molding one material over another, thereby enabling the creation of complex, multi-material products with enhanced functionalities. This process is integral to a range of industries, from automotive to consumer electronics, due to its ability to improve product aesthetics, durability, and user comfort.

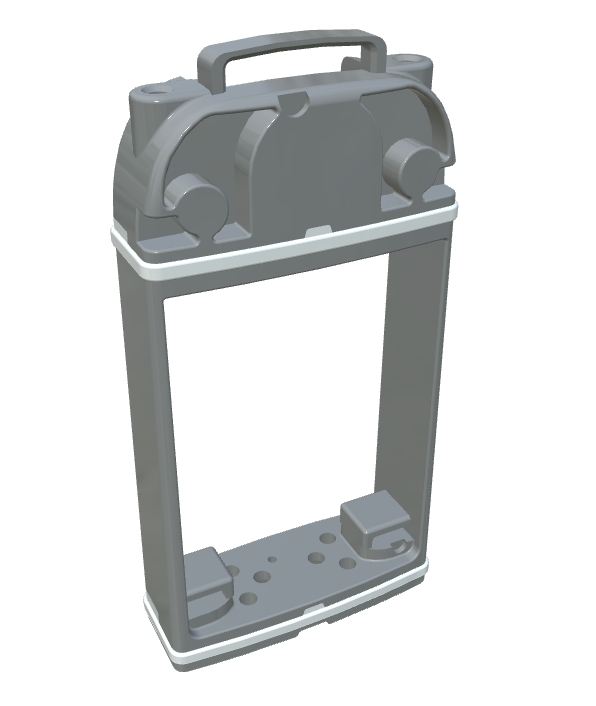

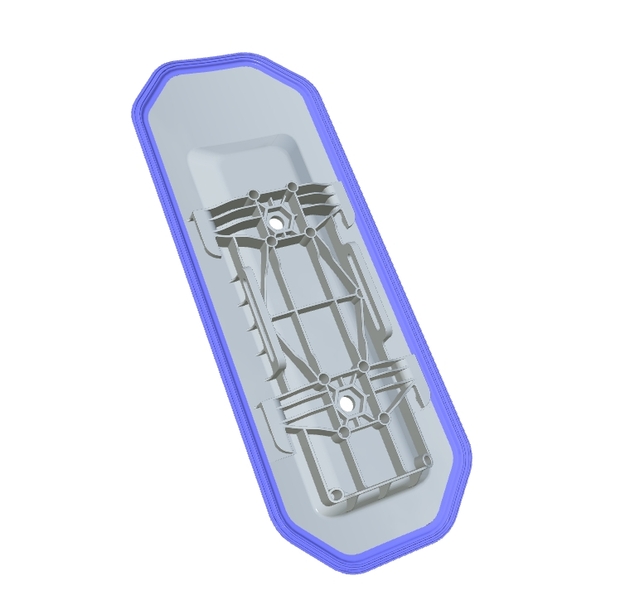

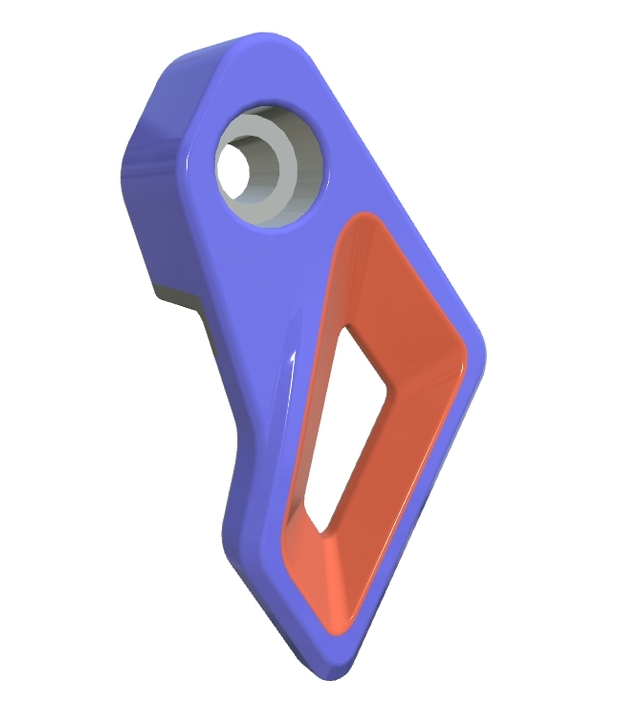

One of the core advantages of the **overmolding process** is its ability to combine different overmolding materials, such as plastics and silicones, to create a product that maximizes the strengths of each component. This technique is especially beneficial for products that require enhanced grip, soft-touch surfaces, or sealed protection. For instance, in plastic overmolding, a rigid plastic substrate might be coated with a softer material to provide ergonomic benefits or vibration damping. Silicone overmolding is famously utilized in medical devices and electronics due to its flexibility and resistance to environmental factors.

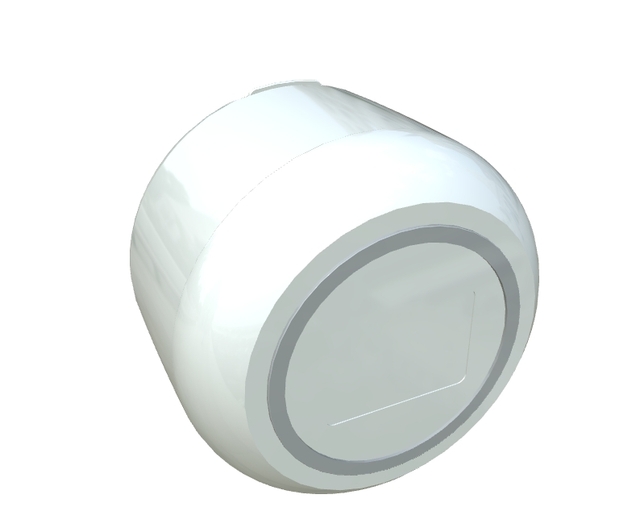

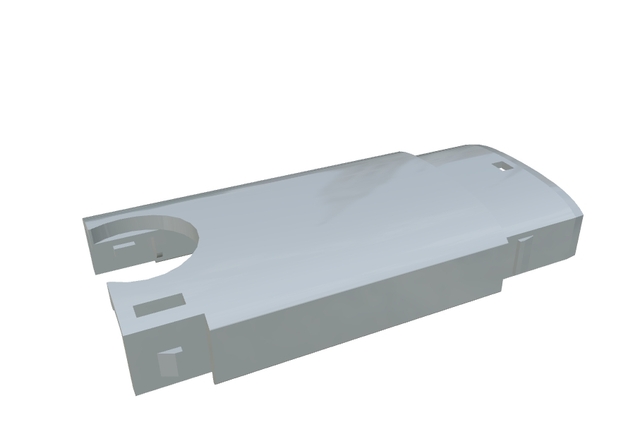

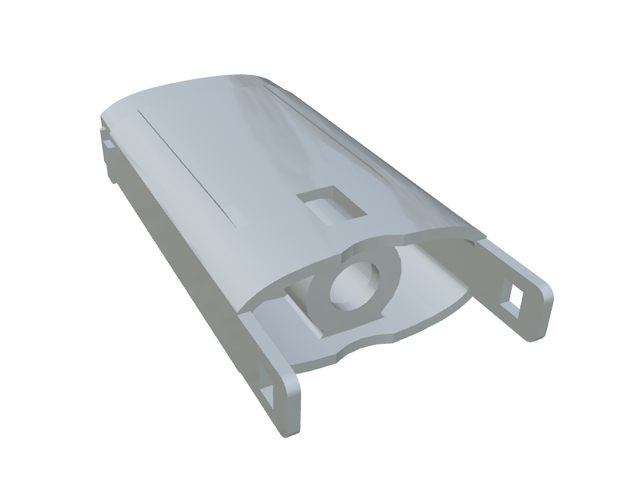

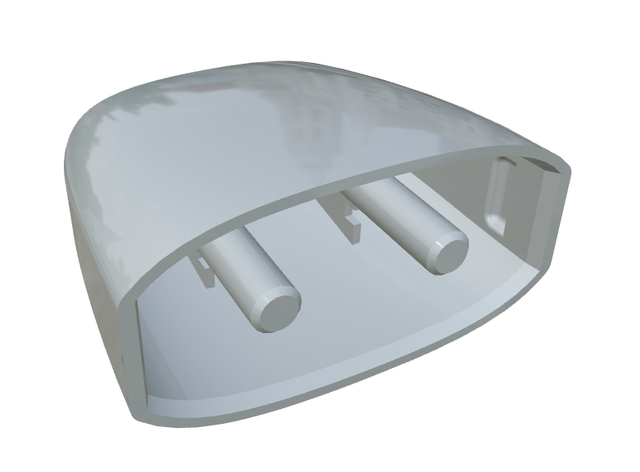

The design flexibility offered by **overmolding techniques** means engineers can create products that were previously impossible with single-material molds, optimizing them for both function and design. This feature is remarkably evident in products such as the innovative Dual Plug Inverter Shell. Combining sleek design with functional efficiency, this shell serves as an ideal example of how overmolding can enhance product appeal. Its glossy finish and aerodynamic shape not only ensure that it reduces resistance but also contributes to a high-performance standard in electrical housing solutions.

Moreover, the benefits of the **overmolding process** extend beyond design into areas such as cost efficiency and manufacturing speed. This makes it an attractive option for companies looking to streamline production while maintaining quality. Overmolding design strategies play a critical role in determining the final product quality and must be meticulously planned to ensure compatibility and robust adherence between the materials.

In conclusion, the overmolding process, with its vast array of techniques and material options, offers significant advantages in product development across multiple sectors. Whether it is in creating sturdy and ergonomic plastic goods or sophisticated electrical components like the Dual Plug Inverter Shell, the potential applications of overmolding are vast and continue to expand as new materials and technologies emerge. As companies strive to produce innovative and high-quality products, embracing the possibilities of the overmolding process becomes ever more essential.

Overmolding Process: Techniques, Materials & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.