The overmolding process is a cutting-edge manufacturing technique that has transformed the way products are designed and produced. As companies continue to seek ways to improve product functionality and aesthetic appeal, the use of overmolding materials has become increasingly popular. This technique, which involves applying an additional layer of material over an existing piece, allows designers to create complex parts with enhanced features without compromising durability.

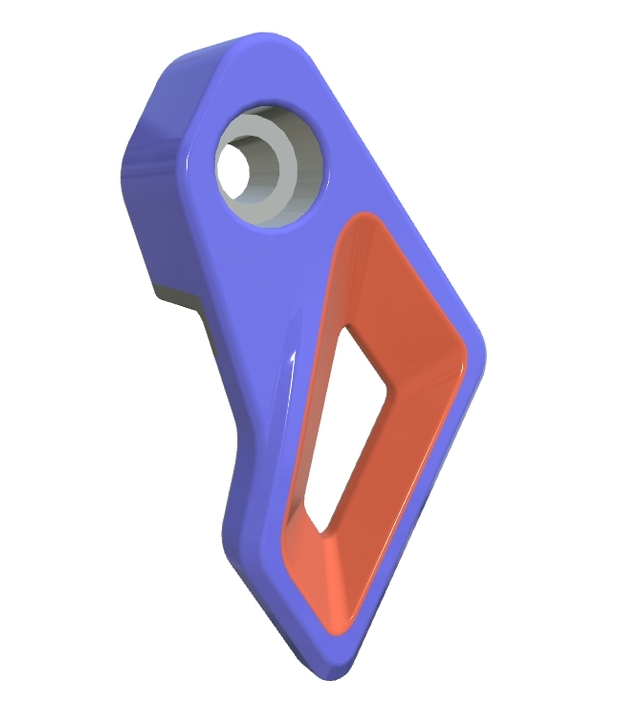

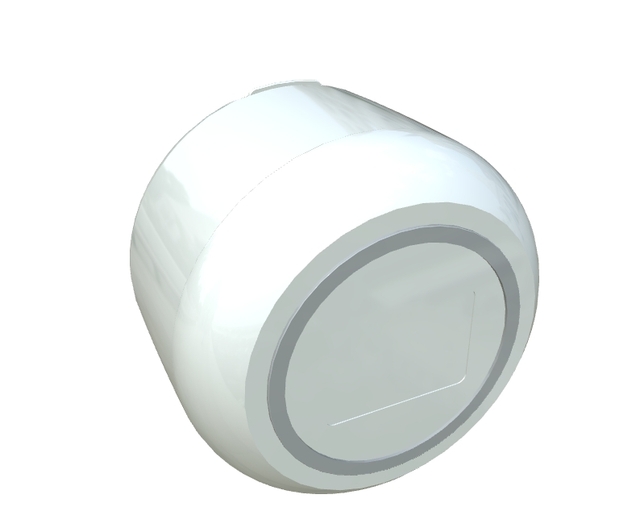

Overmolding is particularly beneficial in the creation of products that require a combination of different material properties. For instance, a rigid plastic part can be overmolded with a soft elastomer to provide a comfortable grip or a sleek finish. By leveraging various overmolding techniques, manufacturers can tailor the tactile and visual attributes of their products, resulting in a more attractive and user-friendly end product. This versatility is seen in many industries, ranging from consumer electronics to automotive components.

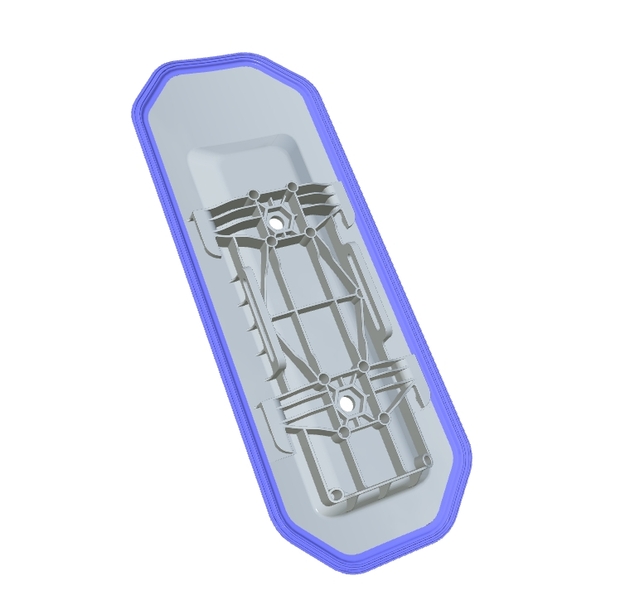

Central to the success of injection overmolding is a meticulous overmolding design that considers the interaction between the substrate and the overmolded material. Understanding how these materials bond can significantly influence the performance and longevity of the finished component. The design must account for the thermal and mechanical properties of both materials to ensure a strong and lasting bond. Furthermore, the placement of gates, vents, and parting lines is crucial to minimize any potential defects and to ensure a seamless finish.

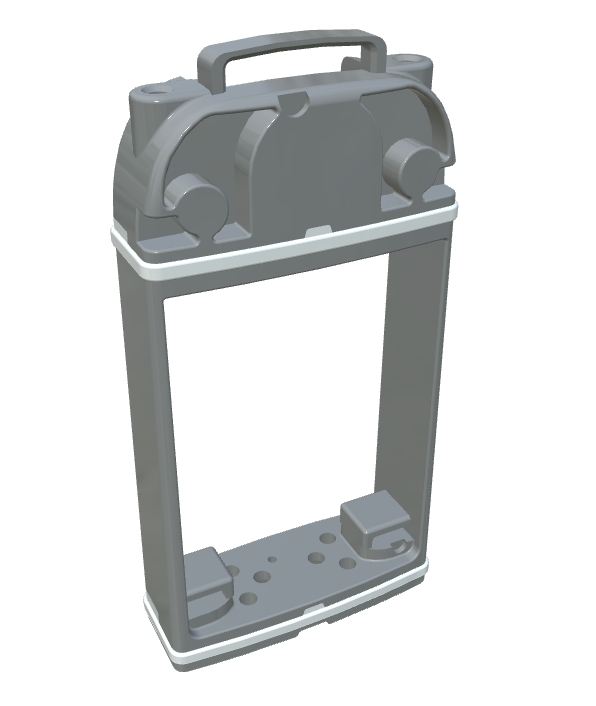

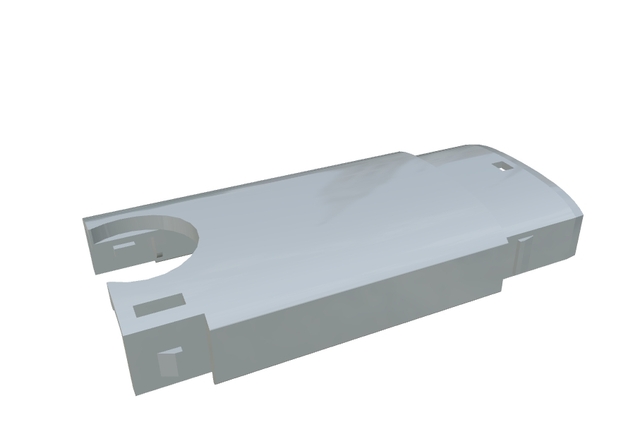

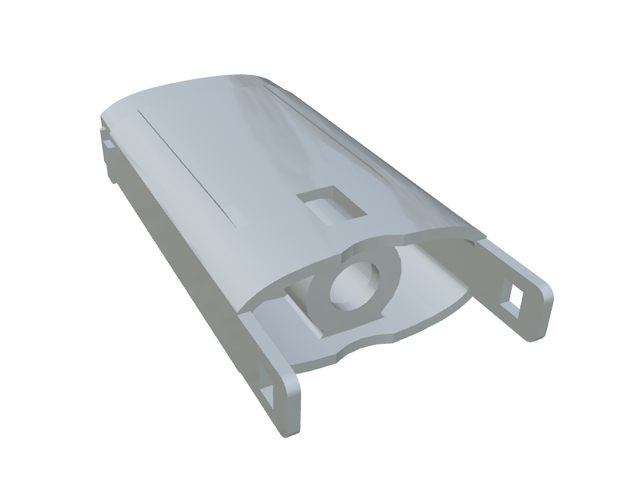

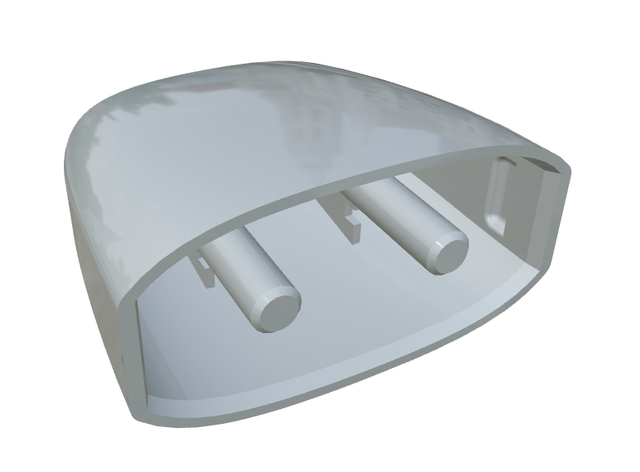

In practical applications, overmolding provides numerous benefits that extend beyond the mere aesthetics. For example, in the design of modern, sleek wall mount holders, overmolding plays a pivotal role in enhancing usability and durability. These holders, constructed with an open-ended design, allow for effortless installation and adaptability with various devices, ensuring that they are both functional and stylish. The durable overmolded materials guarantee a secure fit, thus maintaining stability while offering easy access, ultimately reducing clutter and contributing to a minimalist aesthetic.

Overmolded components are paramount in achieving product designs that combine utility with elegance. The process facilitates the creation of lightweight structures with a smooth, contoured surface that enhances any room decor. This alignment of functionality with visual appeal showcases the true potential of the overmolding process, making it an invaluable technique in modern manufacturing. Whether used to improve grip, add color differentiation, or enhance tactile feedback, overmolding stands out as a vibrant tool in the toolbox of innovative manufacturers.

Unlocking the Overmolding Process: Techniques & Benefits

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.