Insert molding is revolutionizing the manufacturing industry by integrating different materials and components into a single molded part, offering various advantages over traditional methods. This versatile process involves integrating metal inserts, wires, or circuits into a mold before injecting thermoplastic materials to form a completed part. The insert molding process is widely recognized for its ability to enhance product durability and functionality while reducing assembly time and costs.

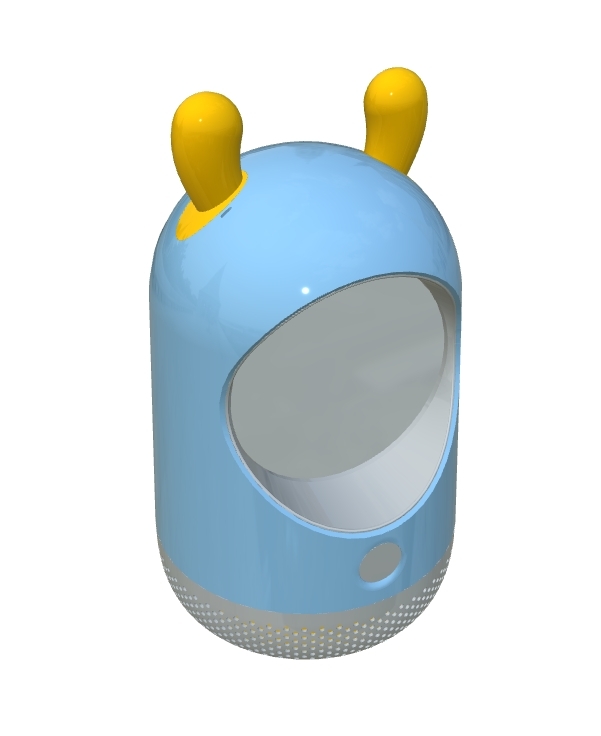

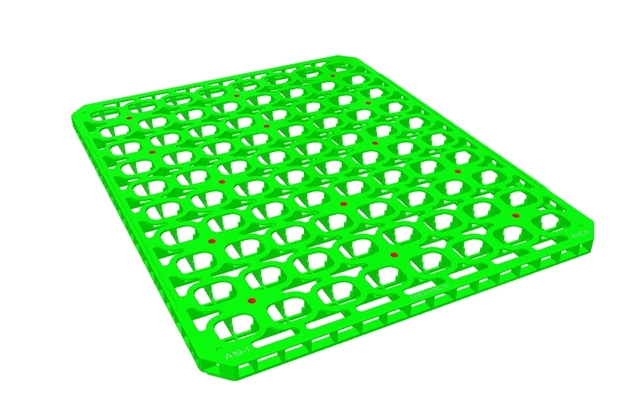

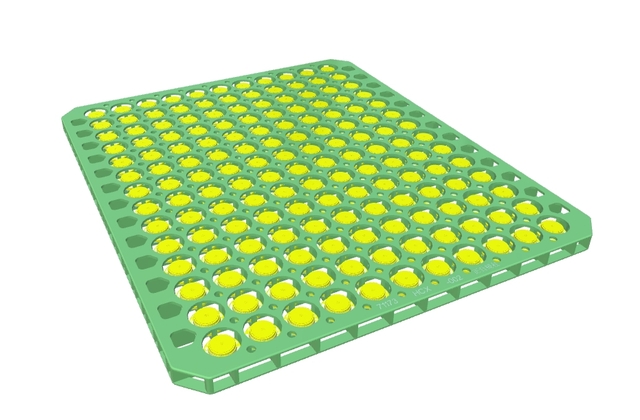

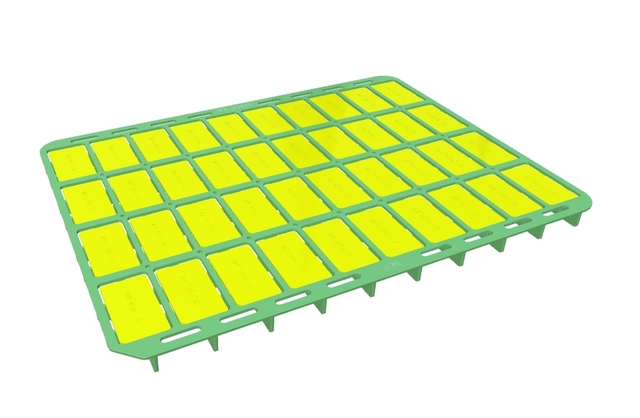

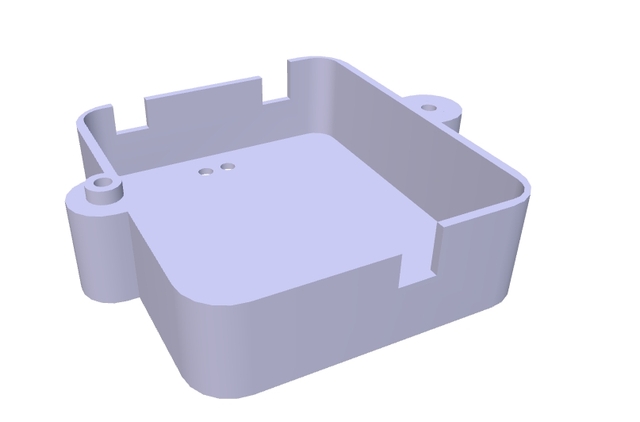

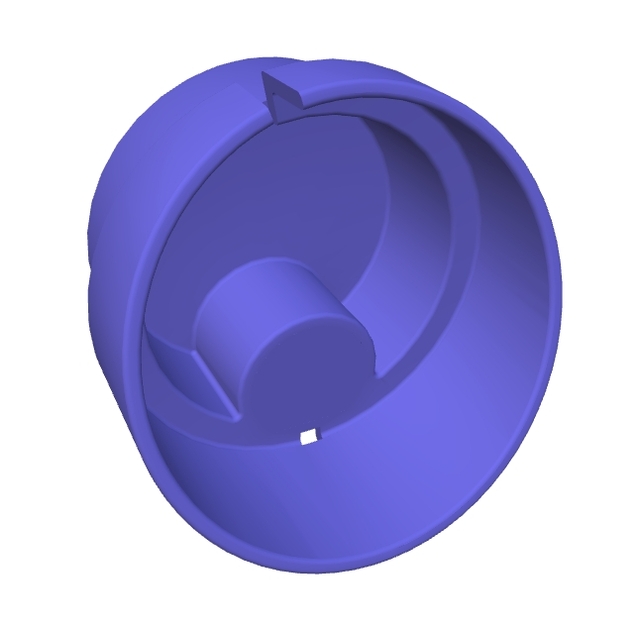

One of the key advantages of insert molding lies in its potential to innovate product design and enhance performance, leading to more efficient and cost-effective manufacturing. Insert molding applications span across various industries, including electronics, automotive, and medical devices, where durable, lightweight, and highly functional components are critical. The technology allows for the incorporation of complex geometries and intricate designs, which are integral to producing products like the Green ArcTech Shell.

The Green ArcTech Shell epitomizes the benefits of insert molding materials, which have been carefully selected to ensure robustness and sustainability. The sleek and ergonomic design, coupled with eco-friendly materials, underscores the environmental commitment of manufacturers employing advanced insert molding technology. Precision-molded elements are engineered for easy assembly and accessibility, making the Green ArcTech Shell an ideal choice for tech enthusiasts and innovators alike.

Insert molding technology not only enables the creation of high-quality products like the Green ArcTech Shell, but it also facilitates the production of items that are highly durable, shock-resistant, and aesthetically pleasing. It is through partnerships with experienced insert molding manufacturers that companies can ensure their products meet the highest standards. These manufacturers offer specialized insert molding services, tailored to meet specific design and functionality requirements.

In conclusion, insert molding is a groundbreaking process that continues to push the boundaries of product design and manufacturing. Its numerous advantages, including enhanced durability, cost efficiency, and innovative applications, make it a favored choice among industries looking to optimize their product offerings. Products like the Green ArcTech Shell, which boast cutting-edge design and sustainable materials, exemplify the remarkable possibilities that insert molding brings to the industry. As demand for high-performance, eco-friendly products rises, the significance of insert molding in shaping the future of manufacturing only grows.

Revolutionizing Manufacturing with Insert Molding Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.