The insert molding process is a prominent technique in the manufacturing industry, offering significant advantages, especially when creating intricate and durable components. This innovative technology involves molding plastic around pre-formed components, such as metal parts, to create a single, cohesive product. Insert molding is highly valued for its ability to enhance product structural integrity and reduce assembly time.

In terms of applications, insert molding is widely used across various industries, including automotive, electronics, and consumer goods. The process allows for the integration of metal and plastic into a single part, making it highly advantageous for complex assemblies. Insert molding manufacturers often leverage this technology for producing parts like connectors, switches, and custom components that require high precision and reliability. When comparing insert molding vs injection molding, insert molding stands out for its ability to incorporate multiple materials seamlessly.

The materials used in insert molding are carefully selected based on the application requirements. Typically, thermoplastics are used for their moldability and durability. Insert molding design plays a crucial role in ensuring the final part's functionality and performance. High precision insert molding demands meticulous planning and execution to achieve the desired tolerances and specifications.

Insert molding services are crucial for businesses looking to innovate and improve their product offerings. Companies specializing in insert molding often provide comprehensive solutions, from initial design consultation to final product manufacturing. These services help clients optimize product design, reduce waste, and enhance overall product quality. Industrial insert molding, in particular, benefits large-scale operations by enabling efficient production of complex parts.

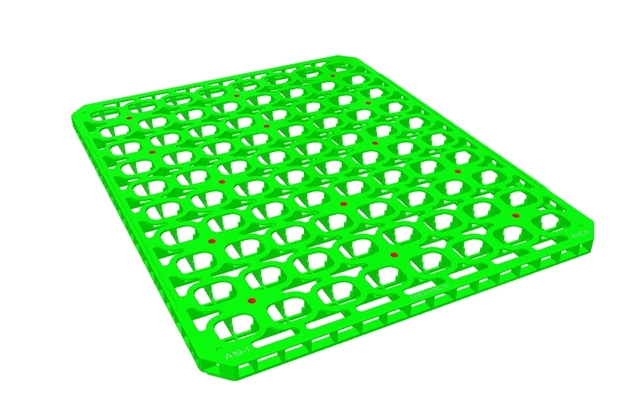

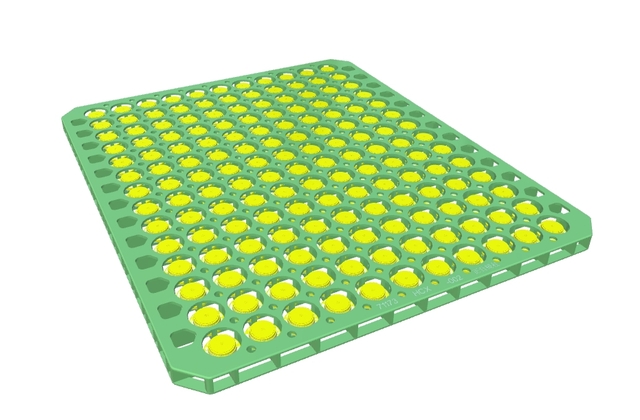

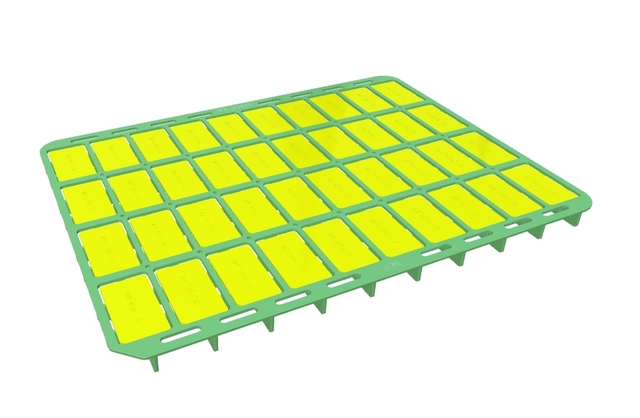

An excellent example of the application of insert molding can be seen in the creation of the eco-friendly green and yellow pallet. This innovative product showcases the versatility of insert molding technology. Designed with both efficiency and sustainability in mind, the pallet features robust materials for enhanced durability while maintaining a lightweight structure for easy handling. The vibrant green framework interspersed with yellow panels not only offers a modern aesthetic but also ensures excellent visibility, particularly in warehouse settings. The design provides for easy stacking and secure footing, demonstrating how insert molding can optimize space and functionality.

Incorporating insert molding into manufacturing processes can significantly impact product development and optimization. Whether you're looking to produce intricate components or develop eco-friendly products like the green and yellow pallet, insert molding technology offers the benefits of precision, durability, and efficiency. By choosing the right insert molding manufacturer, companies can enhance their logistics and production capabilities, creating products that are both practical and environmentally conscious.

Understanding the Insert Molding Process: Advantages and Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.