Insert molding is a groundbreaking manufacturing technique that is significantly altering the landscape of product development in multiple industries. One particularly innovative application of insert molding technology is seen in the production of devices like the Smart Interactive Buddy, highlighting how this method can be leveraged to integrate advanced features seamlessly into consumer products.

The insert molding process involves encapsulating a component, such as a metal insert, within plastic to enhance the product's durability and functionality. This is particularly beneficial in creating products like the Smart Interactive Buddy, where the aesthetic and functional design must be advanced and sophisticated. The technology allows manufacturers to meet these high standards by providing flexibility in design, enabling the incorporation of complex components into a single molded piece.

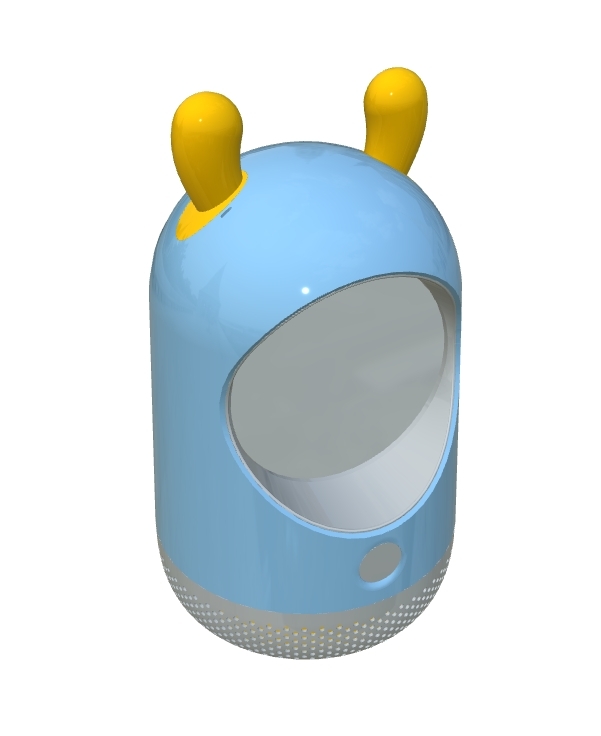

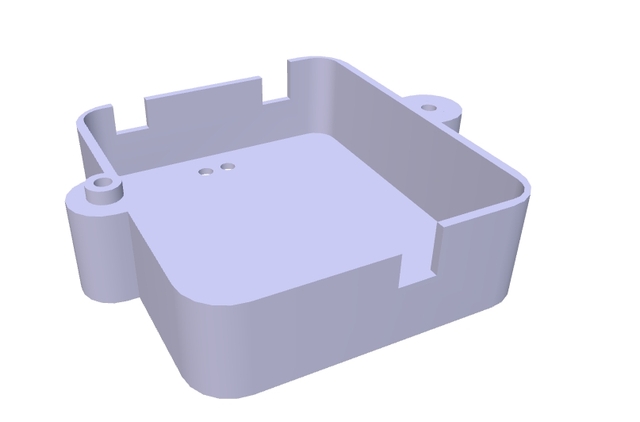

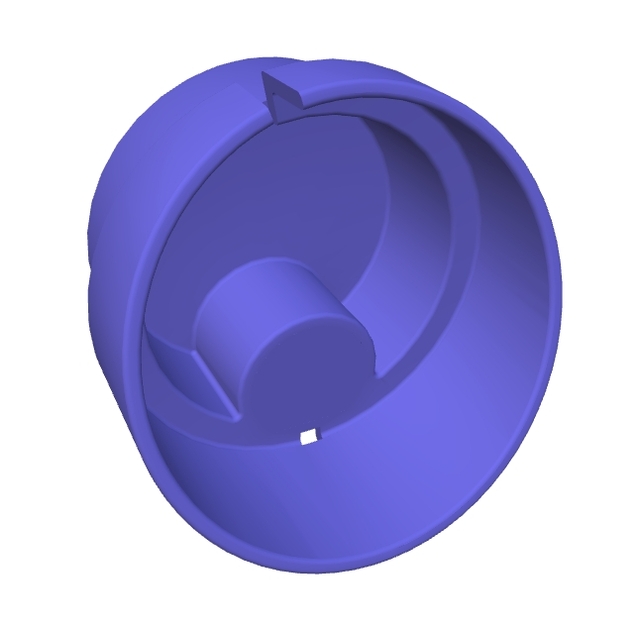

Custom insert molding is a key driver in the development of unique and personalized products. It offers the ability to tailor the materials and design to the specific requirements of a project, making it a preferred choice among insert molding manufacturers for producing innovative solutions like the Smart Interactive Buddy. The device's smooth blue exterior, integrated with high-fidelity speakers in the base and a responsive AI interface, exemplifies how insert molding can be used to blend creative and functional design elements seamlessly.

Furthermore, insert molding materials play a crucial role in ensuring that products are not only visually appealing but also robust and reliable. In comparison to traditional methods, such as injection molding, insert molding provides superior bond strength and reduces assembly time, resulting in a product that stands out in terms of quality and longevity. For the Smart Interactive Buddy, this means a more durable, user-friendly product that can withstand the rigors of daily use while maintaining a sleek and modern aesthetic.

Insert molding applications are extensive and diverse, encompassing industries like consumer electronics, automotive, and medical devices. By integrating components such as circuits or sensors directly into the mold, manufacturers can produce sophisticated devices like the Smart Interactive Buddy at scale, emphasizing the versatile and innovative nature of insert molding technology.

In essence, the use of insert molding in creating the Smart Interactive Buddy showcases how this advanced manufacturing technique can be harnessed to produce cutting-edge consumer products that are both practical and appealing. As the demand for high-tech, aesthetically pleasing devices continues to rise, insert molding will undoubtedly remain a pivotal process in the toolkit of modern manufacturers, paving the way for future innovations.

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.