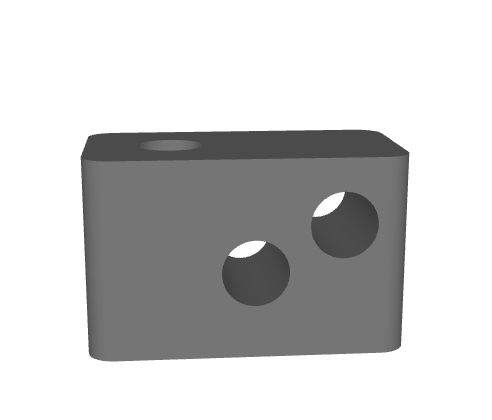

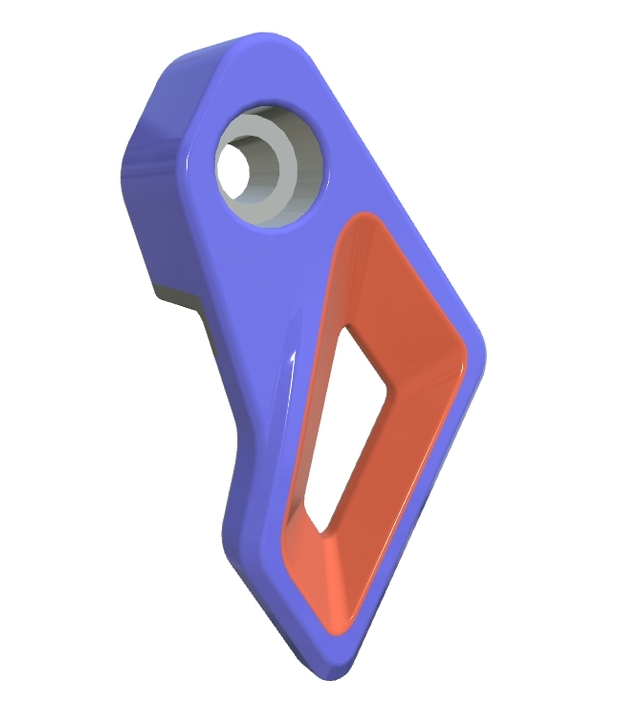

The **injection molding process** is a fundamental component in the manufacturing sector, especially for producing intricate and precision-based products at scale. This technique involves injecting molten material into a mold where it cools and solidifies, taking the shape of the mold cavity. Predominantly used for fabricating parts from thermoplastic and thermosetting plastic materials, injection molding provides manufacturers with extensive flexibility in design and production. Companies that specialize in plastic injection molding often utilize advanced injection molding machines that offer precision, efficiency, and high production speeds.

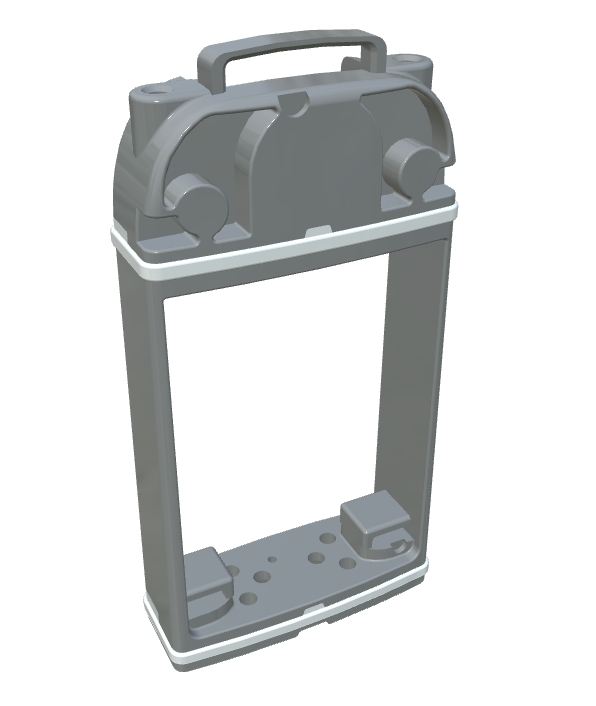

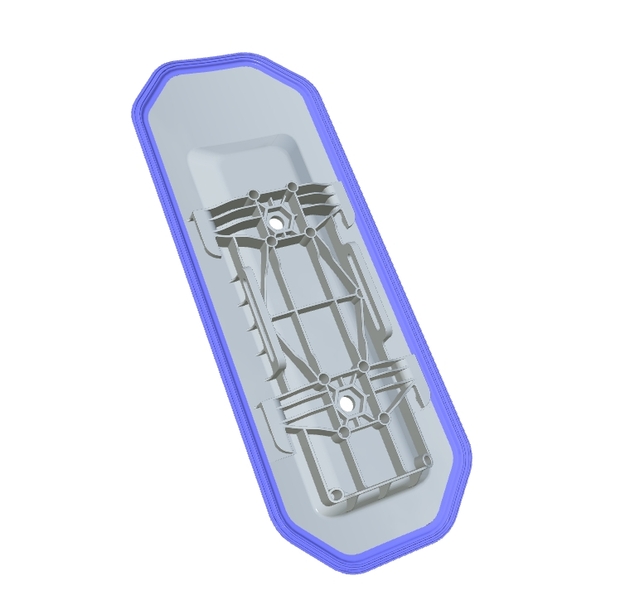

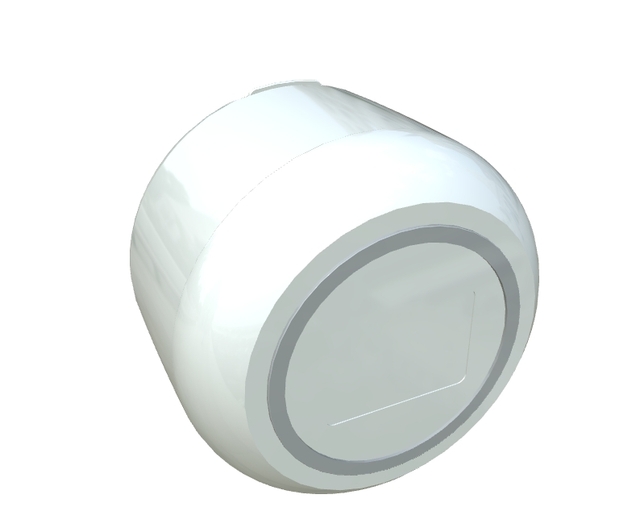

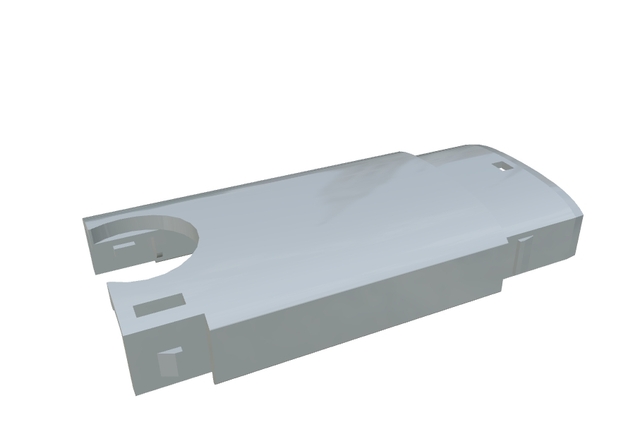

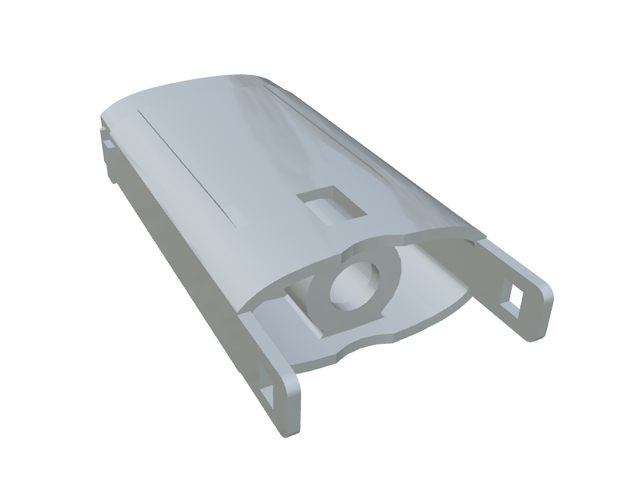

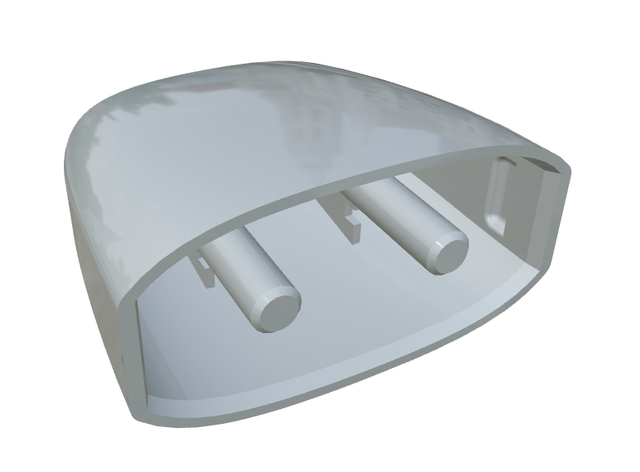

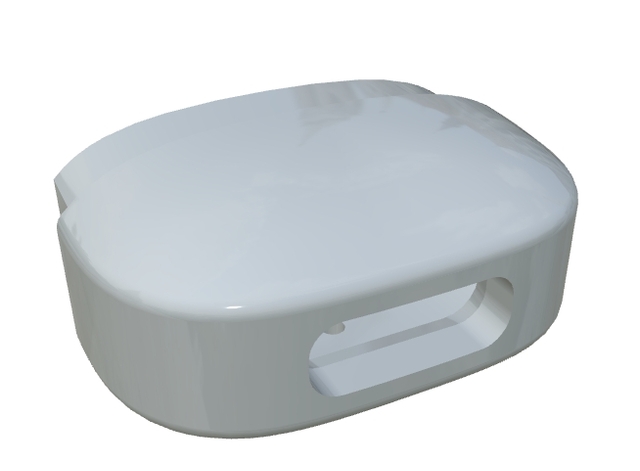

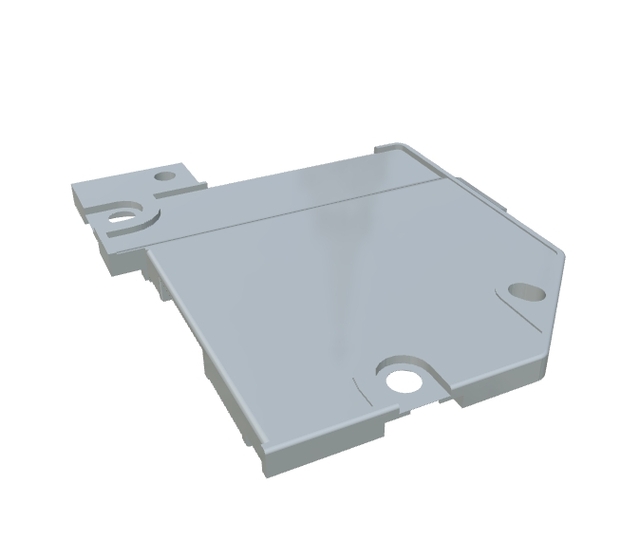

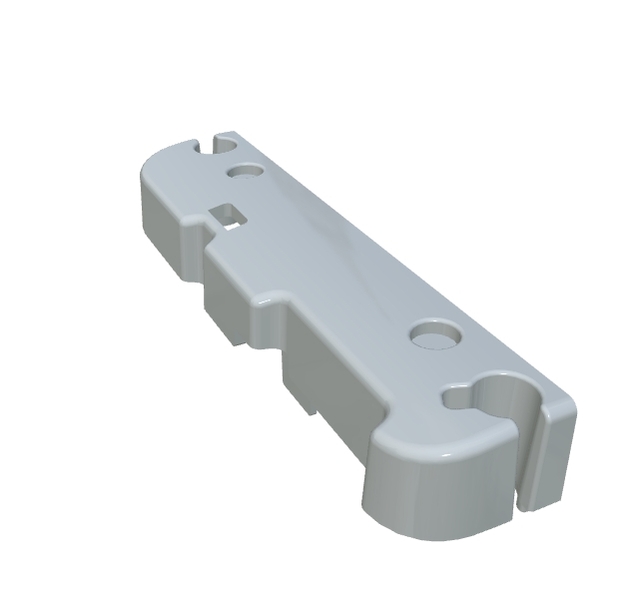

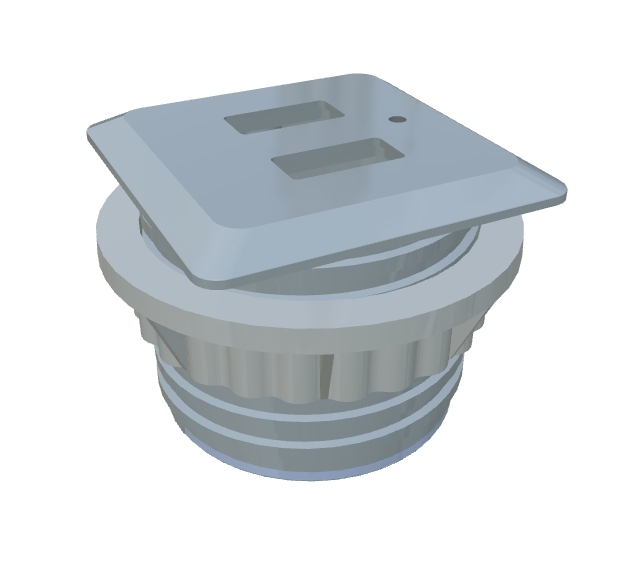

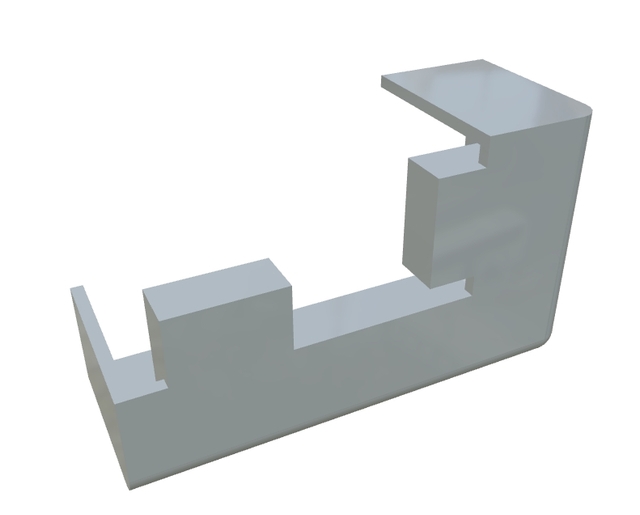

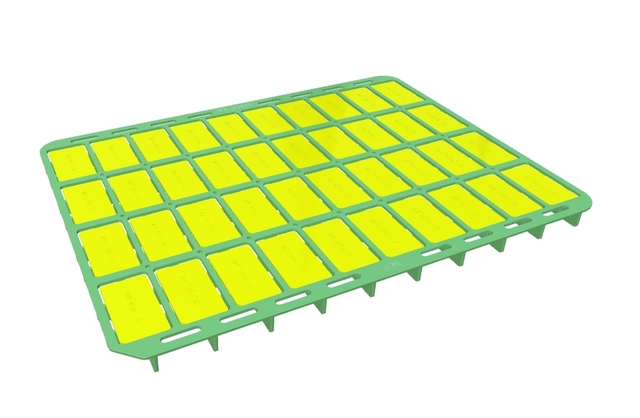

In the domain of construction and architecture, custom injection molding plays a pivotal role in creating components that are not only functional but also aesthetically appealing. An exemplary product is the architectural parapet cap, which benefits greatly from this sophisticated manufacturing technology. The injection molding process ensures that these caps are made from durable, high-quality materials capable of withstanding rigorous weather conditions, thus providing reliable protection and optimal water runoff. These advantages make them an attractive option for builders and architects who demand both durability and elegance in their designs.

Moreover, companies providing injection molding services cater to a wide array of industries, from automotive to consumer goods, allowing for the mass production of custom parts. When it comes to injection molding design and materials, the possibilities are virtually limitless. Manufacturers select injection molding materials that offer the best properties, such as tensile strength, thermal stability, and resistance to chemicals. This is especially important in industrial injection molding where parts must adhere to strict safety and functionality standards. The architectural parapet cap is a clear example of how well-optimized design and material selection can culminate in a product that not only meets functional requirements but also complements modern architectural aesthetics.

In conclusion, the injection molding process is critical for manufacturing a wide range of products efficiently and affordably, offering both versatility and precision. Its application in crafting products like the architectural parapet cap highlights the process’s contribution to innovative building solutions. With ongoing advancements in injection molding technology and materials, industries can expect even greater versatility and expanded possibilities in custom injection molding, making it an invaluable asset in modern manufacturing and construction.

Mastering the Injection Molding Process for Precision Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.