CNC machining is not just a manufacturing process; it is the heart of modern engineering, intricately tied to the efficient creation of automotive parts and groundbreaking innovations in various sectors. Companies globally have harnessed the power of CNC manufacturing to produce precision-engineered automotive fuel system components like fuel injectors and fuel pumps, indispensable in optimizing fuel efficiency and performance.

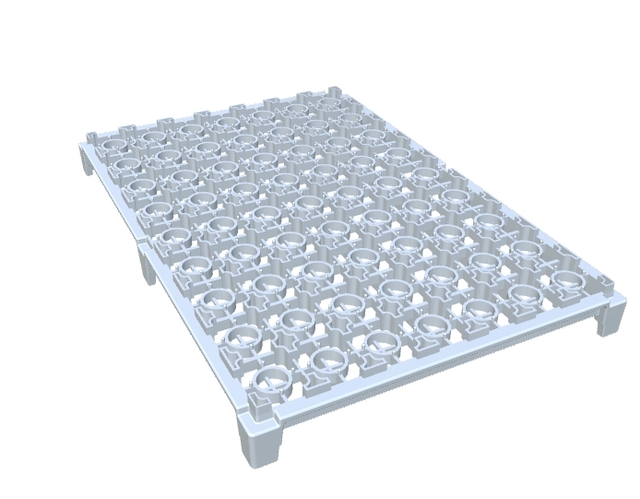

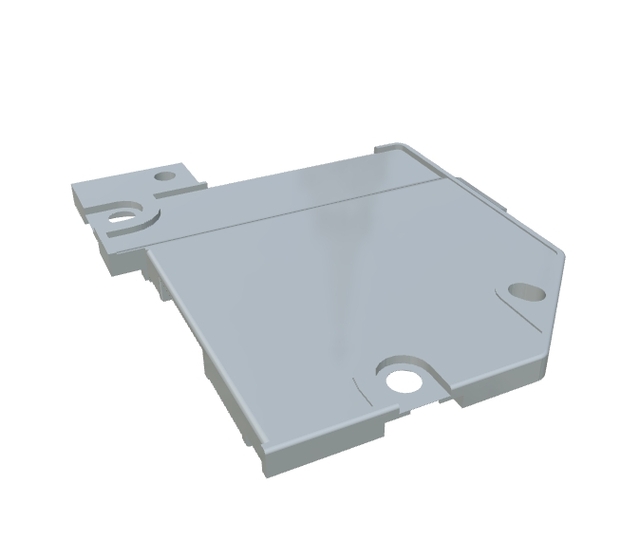

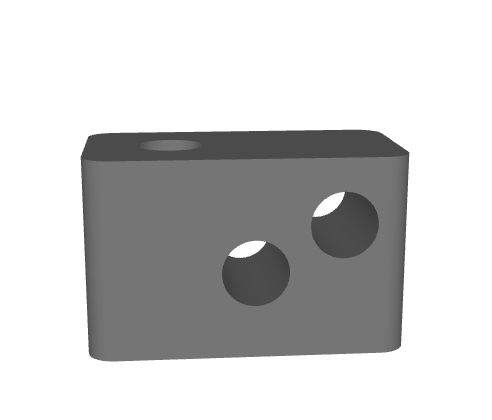

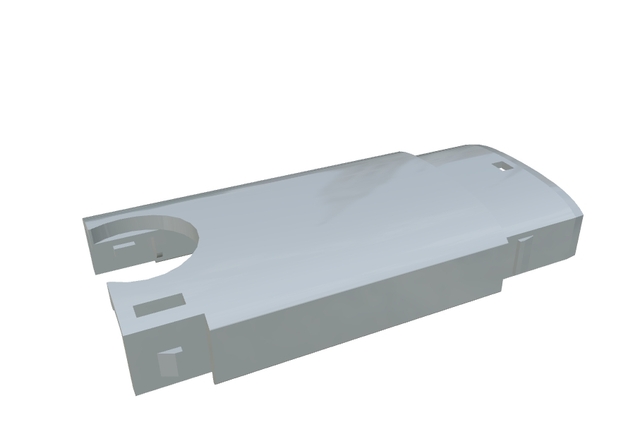

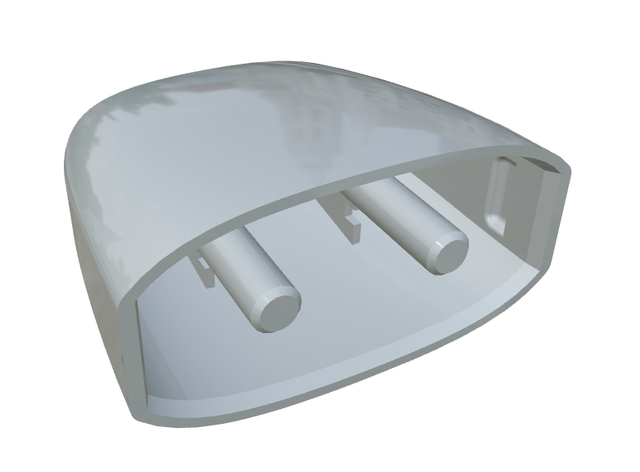

The journey into CNC machining begins with CNC milling and CNC turning, two crucial facets complementing the technique. These processes, real ambassadors of CNC effective practices, inspire innovations such as the sleek, minimalist design of the Multi-Utility Block. Marrying form with extensive functionality, the block epitomizes custom CNC machining capabilities. Crafted with precision from premium-grade materials, it delivers robustness in a surprisingly lightweight frame. Its minimalist facade, peppered with uniquely proportioned circular cutouts, hides a grand versatility—it seamlessly integrates into various setups from industrial uses to styling for personal organizational needs.

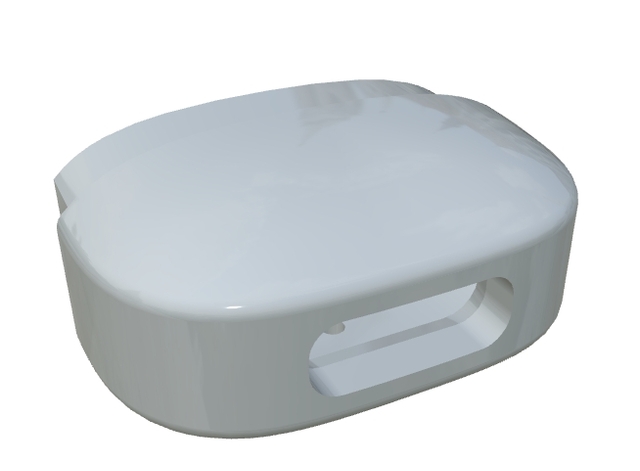

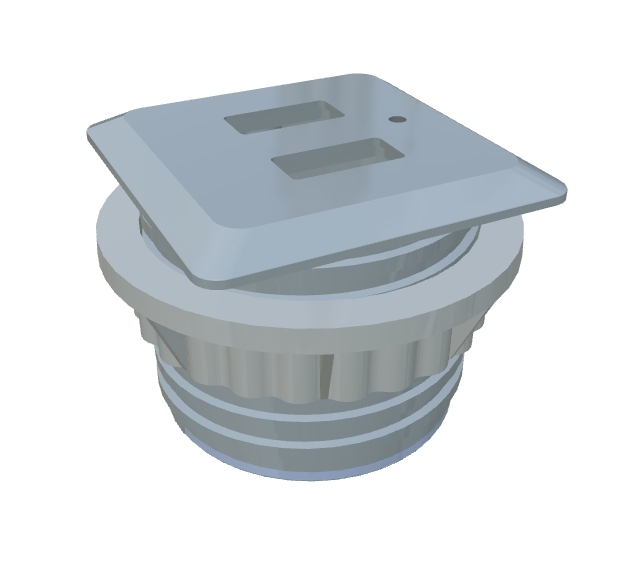

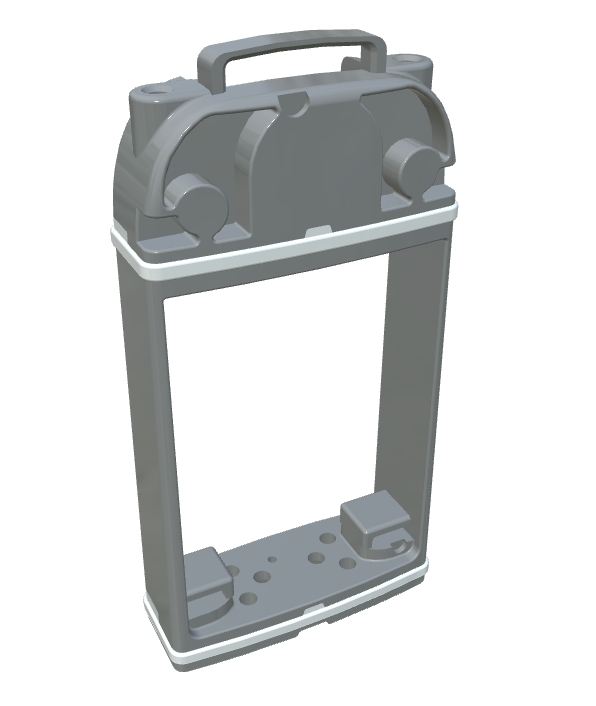

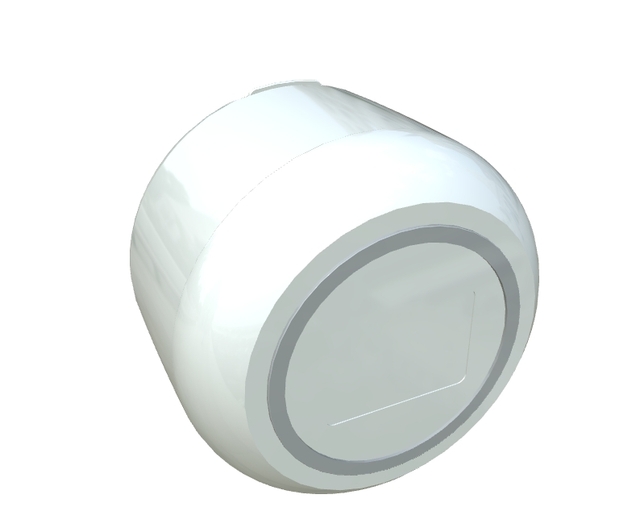

In bringing to life imaginative solutions harnessing CNC magic, arises the Dual-Port Wall Connector. With a steadfast focus on balancing cutting-edge aesthetic and function, this precision-engineered product beckons to tech-savvy and style-conscious hands. Besides its aesthetic allure doused in an elegant matte finish, the dual-port design shares ultimate connectivity while its placement maximizes its operation matching current societal demands for efficient communal space utilization.

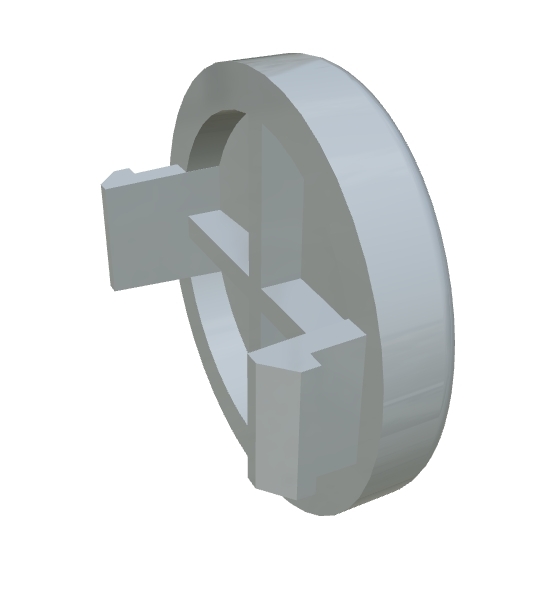

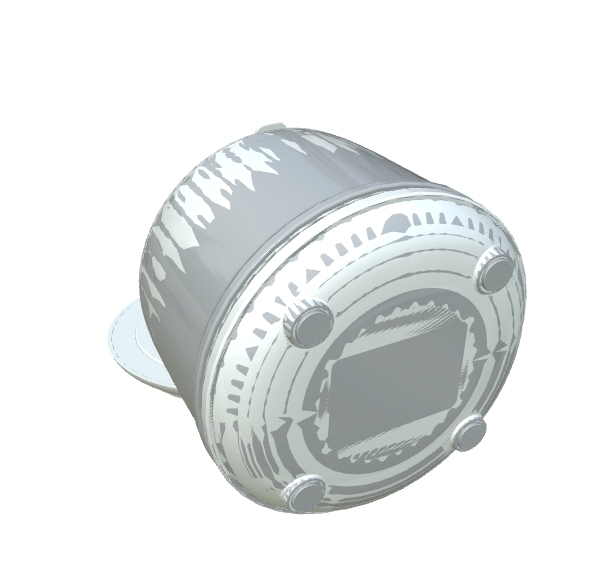

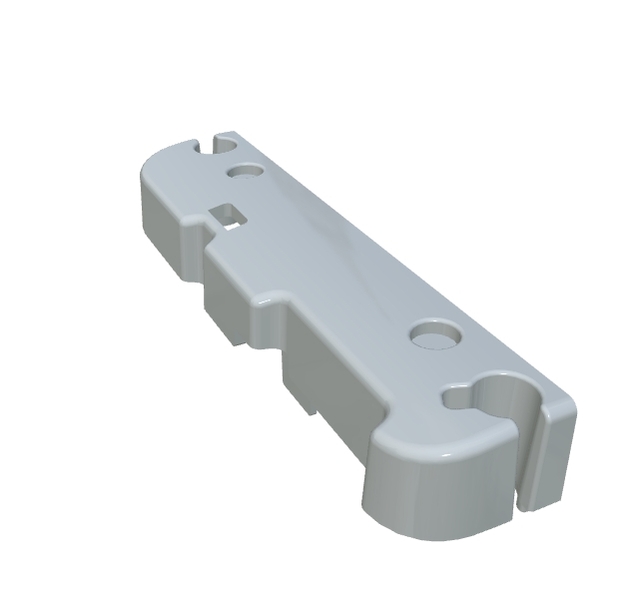

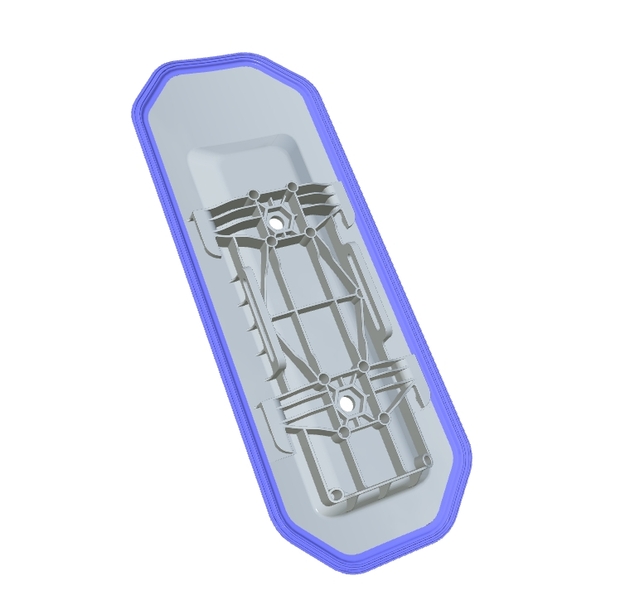

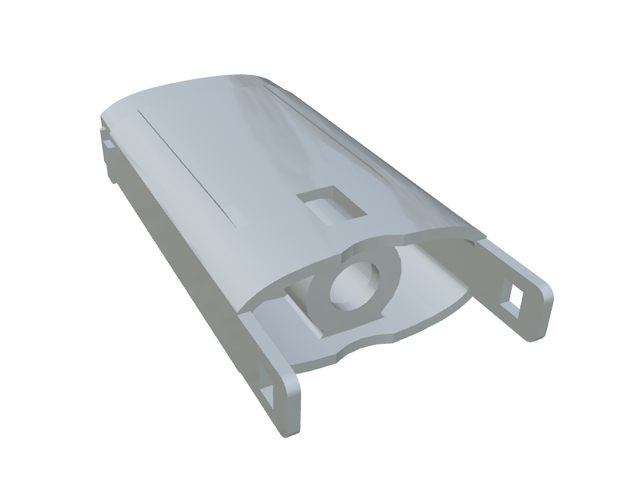

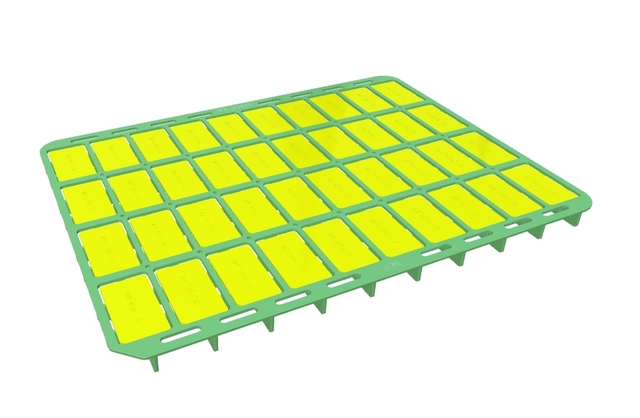

Moreover, the ingenuity found within the CNC machining sphere breeds creations encapsulated expertly in the Rectangular Pneumatic Manifold Connector. Exemplifying technological advancements, this innovation is poised for seamless integration across extravagant pneumatic frameworks. Each angle and relief on the outer surface speaks loudly of meticulous care through enhanced airflow functionality, granting potentially indispensable upgrades within ever-evolving mechanical adventures. Industry standards affirm its durability, quietly instigating zeal in engineering wonders through stylish customizable reliability.

CNC machining perpetuates a narrative deeply interwoven within the themes of advancement, adornment, and unexplored futuristic ascent. A mesmerizing elegant alliance manifests across generations—its fervent touch breathing life magnificently within products truly acknowledging creators of boldly ambitious worlds.

CNC Machining: Precision Innovations in Automotive Parts

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

CNC Machining: Precision Innovations in Automotive Parts

Mastering the Overmolding Process for Superior Design

Overmolding Process: Revolutionizing Material Technology

Overmolding Innovations: Unveiling the HexAlign Bracket

Overmolding Techniques: Revolutionizing Smart Lock Design

Unlocking the Overmolding Process: Techniques & Benefits

Mastering the Overmolding Process for Enhanced Products

Overmolding Process: Techniques, Materials & Applications

Exploring Advanced Overmolding Techniques in Modern Manufacturing

Understanding the Insert Molding Process: Advantages and Applications