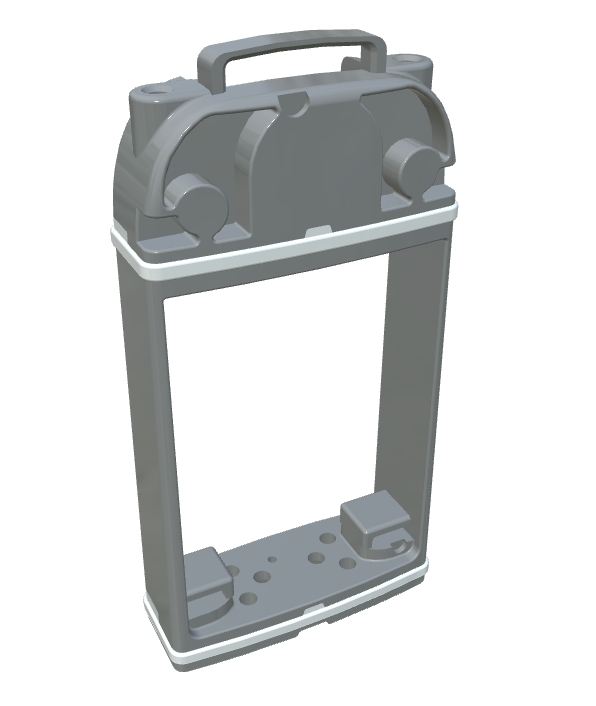

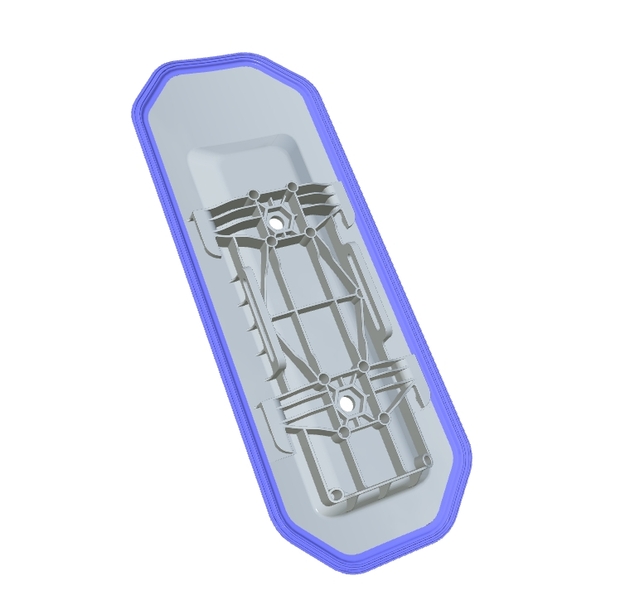

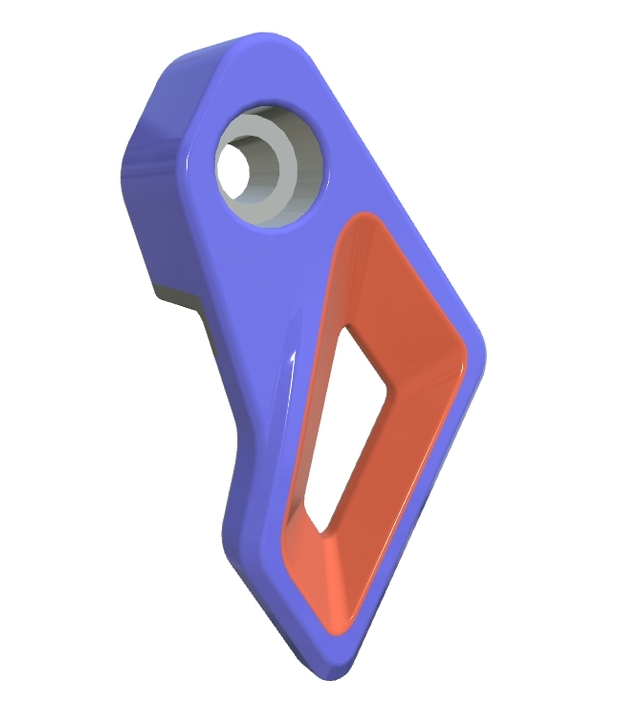

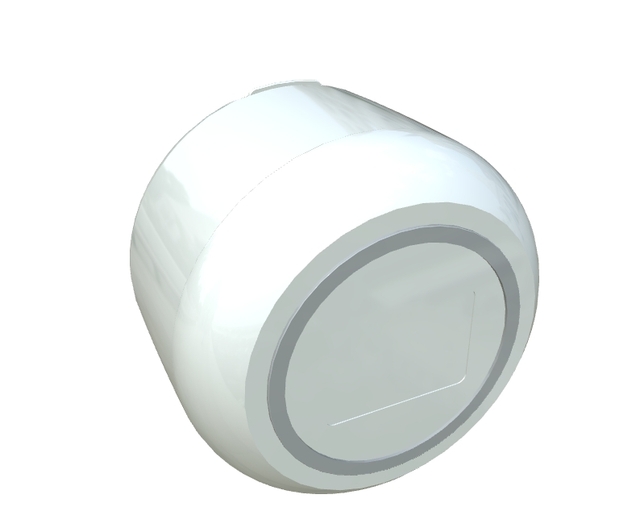

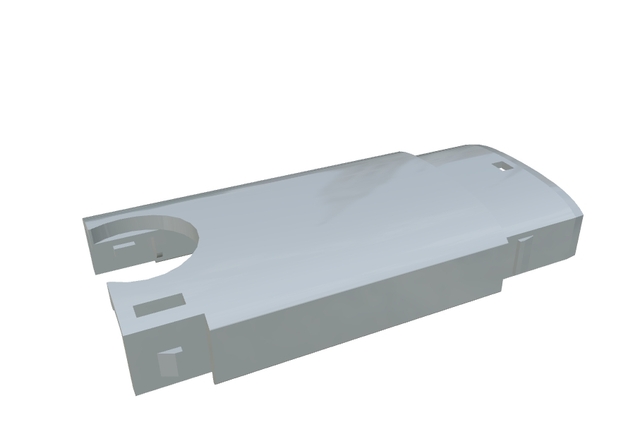

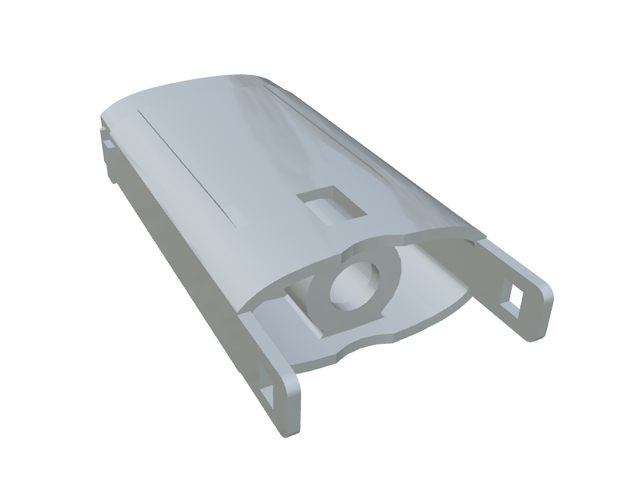

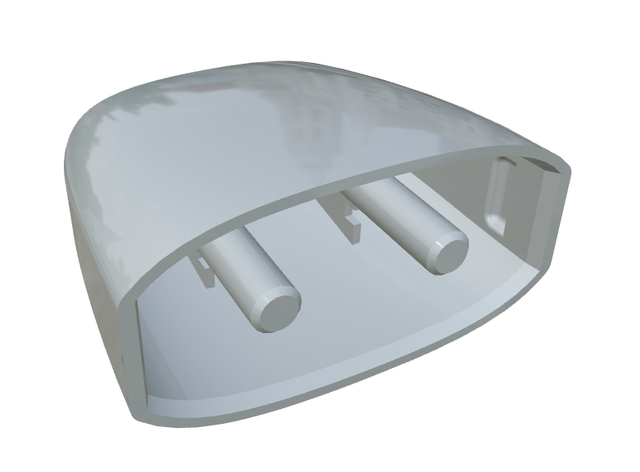

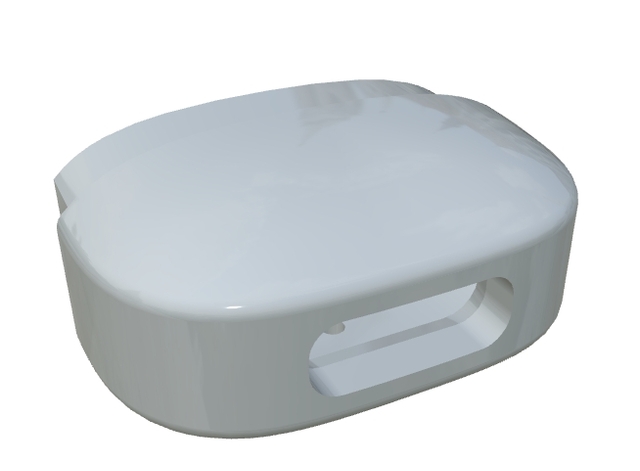

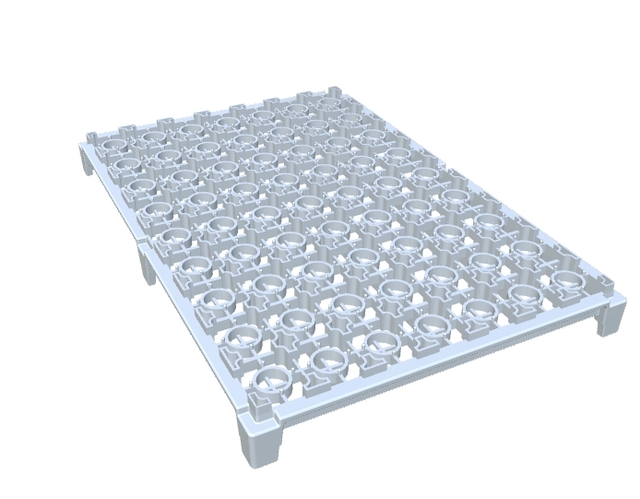

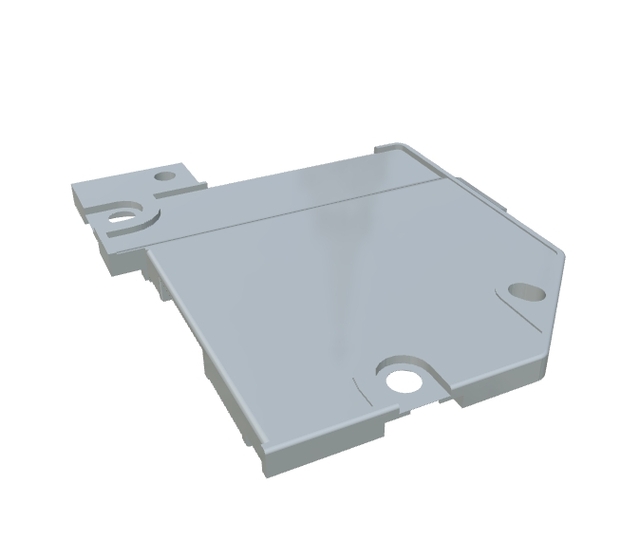

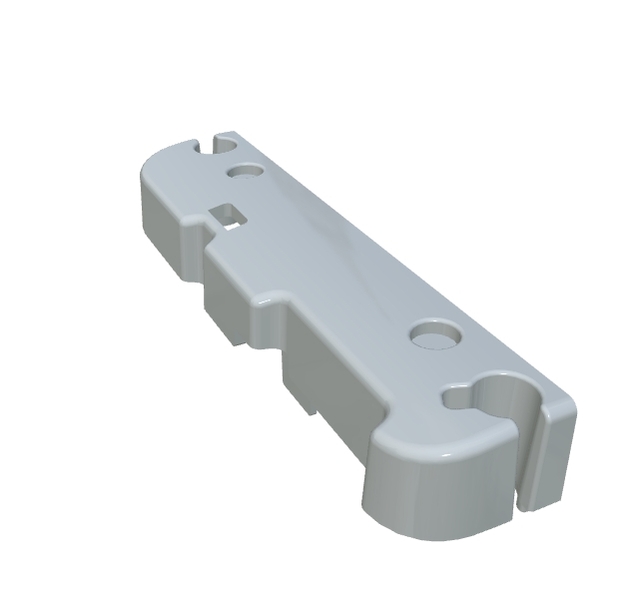

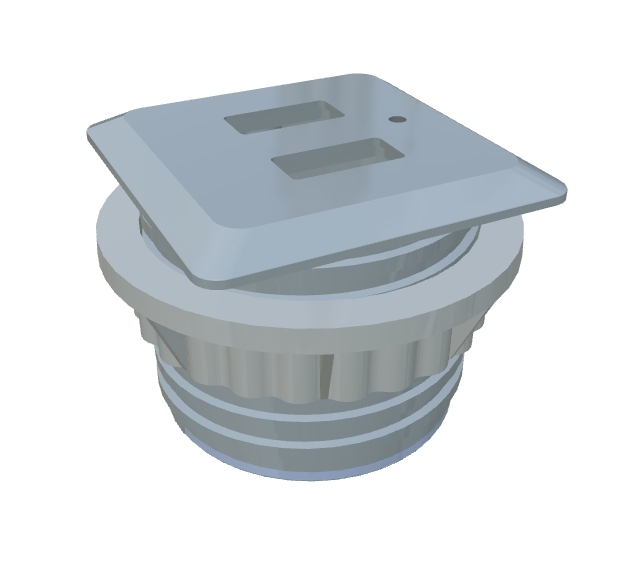

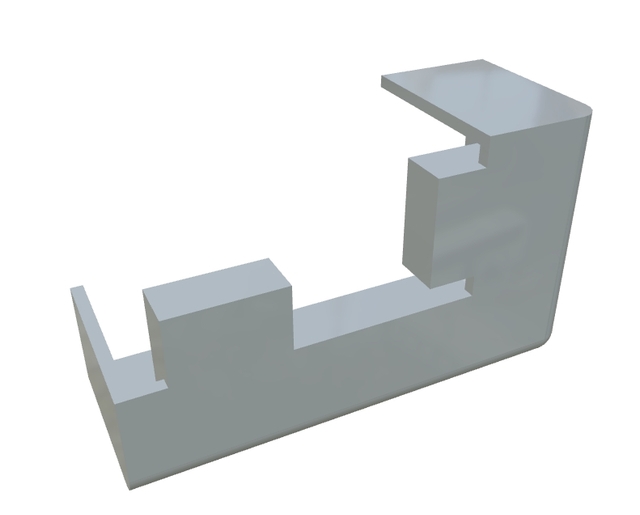

The injection molding process is a pivotal technique in the production of high-quality, durable products, such as the innovative charging and organization hub. At the heart of injection molding manufacturing, this method enhances efficiency and precision, crafting items with complex geometries and sleek finishes that appeal to modern aesthetics. Injection molding machines are vital in this process, adept at melting and injecting materials into molds to form precise, consistent shapes.

Often, the choice of injection molding materials significantly influences the outcome of the manufacturing process. Using robust, glossy materials is crucial when crafting items like our modern charging hub, which seamlessly fits into contemporary settings while offering exceptional durability and elegance. The injection molding design is meticulously created to accommodate various electronic components, ensuring each piece is securely housed within the perfectly shaped and finished hub.

Companies providing injection molding services regularly engage in custom injection molding, tailoring solutions to meet specific design and functional requirements of products like our charging hub. Plastic injection molding is particularly favored for its versatility and cost-effectiveness, making it ideal for producing durable, attractive solutions that enhance everyday tech organization. Our product embodies the seamless integration of style and functionality, illustrating the power and precision of a well-executed injection molding process in elevating consumer products.

Mastering the Injection Molding Process for Modern Products

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.