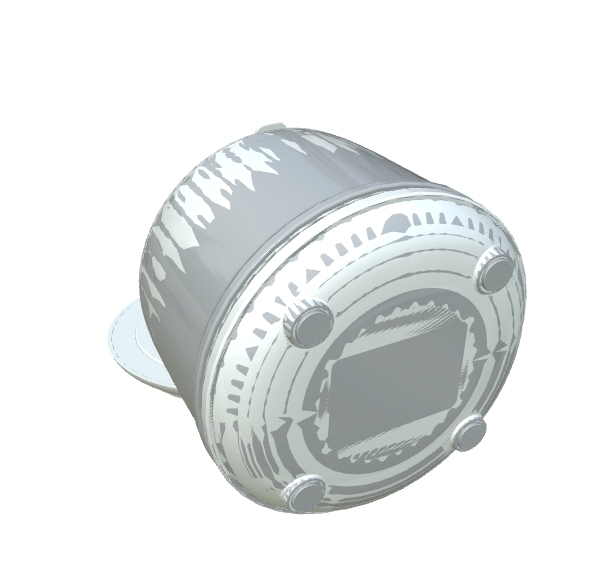

The **injection molding process** is a marvel in manufacturing that enables the production of complex and versatile items with high precision. It is an integral aspect widely adopted by various industries due to its efficiency and ability to produce high-quality components. Key to this process is the **injection molding machine**, an apparatus that injects molten materials into molds to form specific shapes. This revolutionary technology is fundamental in producing everything from everyday household items to cutting-edge tech wearables, such as the remarkable Flexi-Band Tech Bracelet.

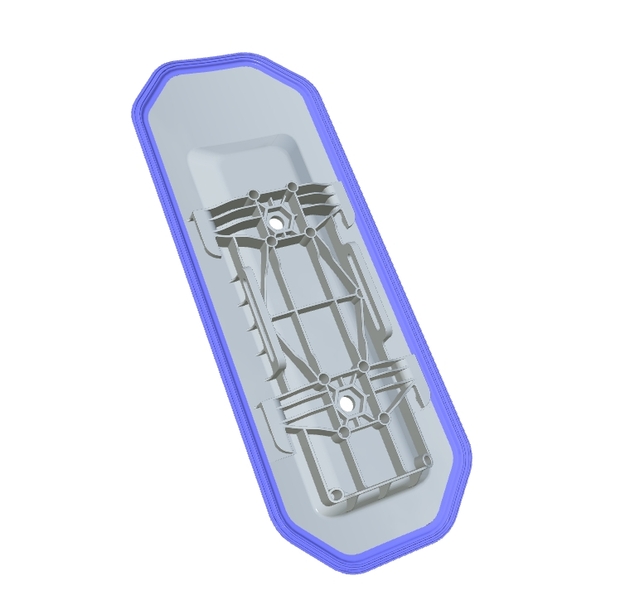

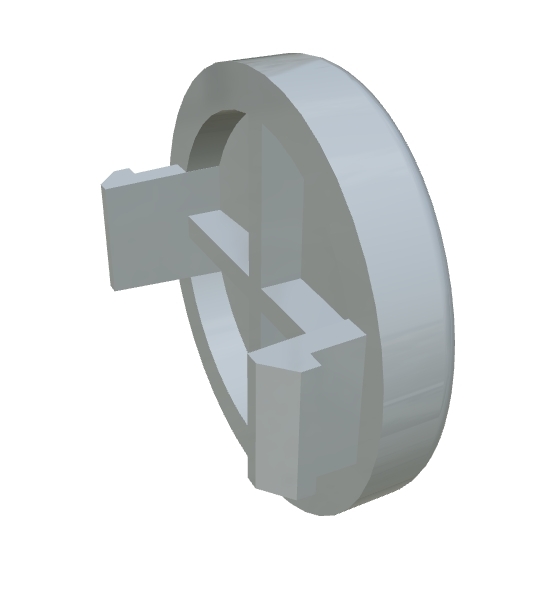

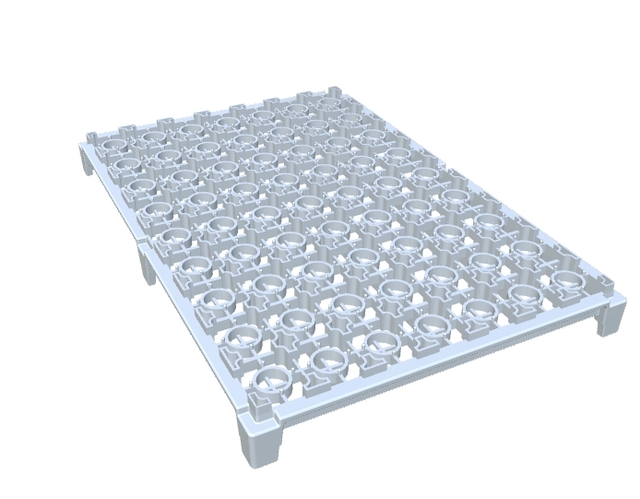

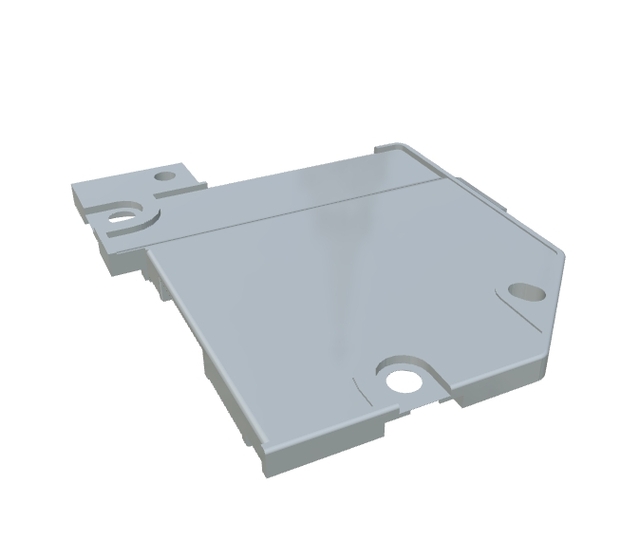

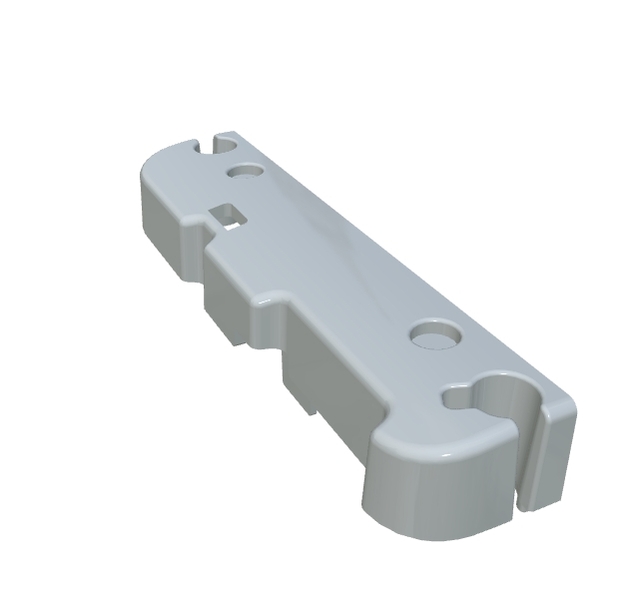

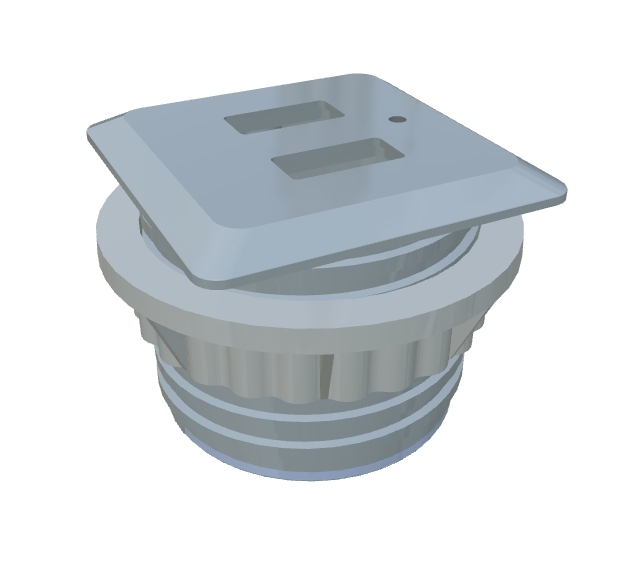

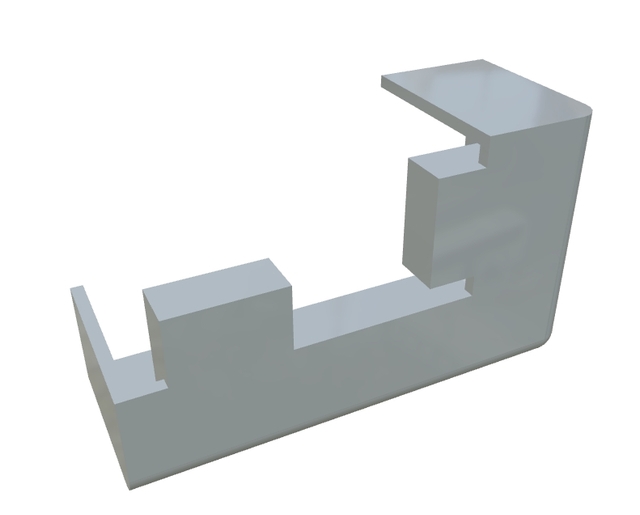

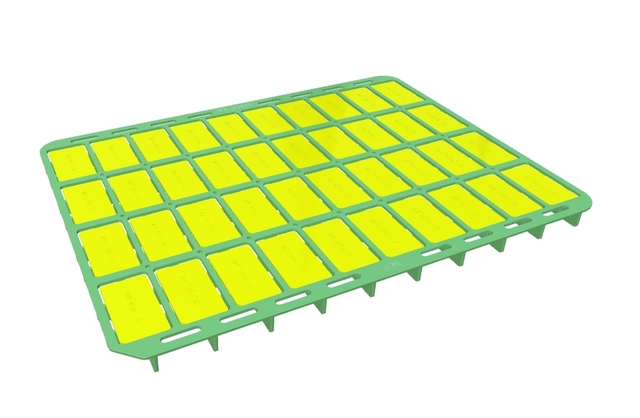

The **injection molding process** begins with selecting the appropriate **injection molding materials** — commonly thermoplastics — which are melted and forced into a mold cavity where they cool and harden into the desired shape. This technique ensures consistency and precision, making it ideal for high-volume manufacturing runs. The benefits of **injection molding plastic** extend beyond mere convenience. It offers reliability in producing products that are sturdy, durable, and aesthetically pleasing. Additionally, custom injection molding allows for bespoke creations that meet specific design and functional requirements, ensuring that no design is too complex to achieve.

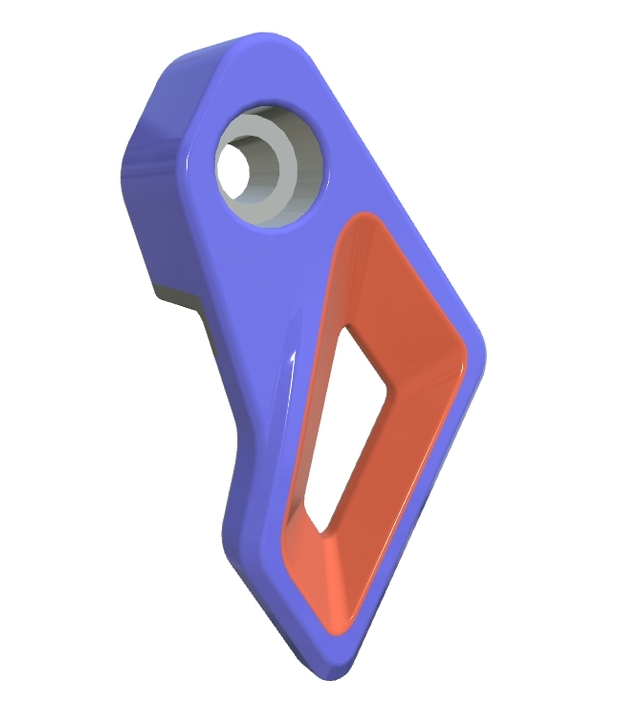

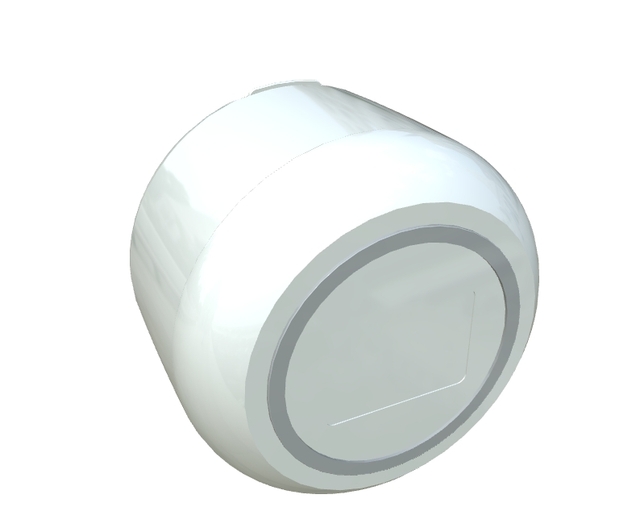

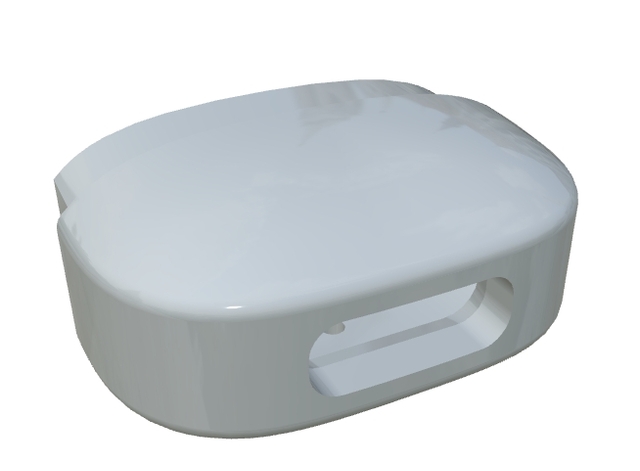

Companies specializing in this field, known as **injection molding companies**, constantly innovate to refine and enhance this process. The Flexi-Band Tech Bracelet stands as a testament to the prowess of precision injection molding. This avant-garde product is crafted from high-grade polished metal, embracing a minimalist aesthetic while incorporating sophisticated technology. Designed for a snug fit, the bracelet seamlessly blends elegance with functionality, tracking wellness metrics and syncing effortlessly with your mobile devices. Indeed, such innovative products highlight the transformative potential of the **injection molding process** in crafting not only practical but also chic accessories adaptable for any occasion.

In summary, the **injection molding process** is an exemplary methodology that offers myriad advantages including consistency, efficiency, and adaptability. It propels industries toward innovative solutions by empowering them with the capability to tailor their creations to fit their precise ambitions. From simple everyday items to sophisticated technological wearables like the Flexi-Band Tech Bracelet, injection molding continues to shape the future of manufacturing.