Plastic injection molding is a versatile manufacturing process that has revolutionized the production of custom plastic parts and components. It involves injecting molten plastic into a mold to create precise, complex shapes with high efficiency and repeatability. The injection molding process is a cornerstone of modern manufacturing, offering immense utility in producing everything from industrial components to consumer products. With advancements in plastic manufacturing techniques, businesses can now enjoy the benefits of high volume plastic production, ensuring their products meet exact specifications with minimal waste.

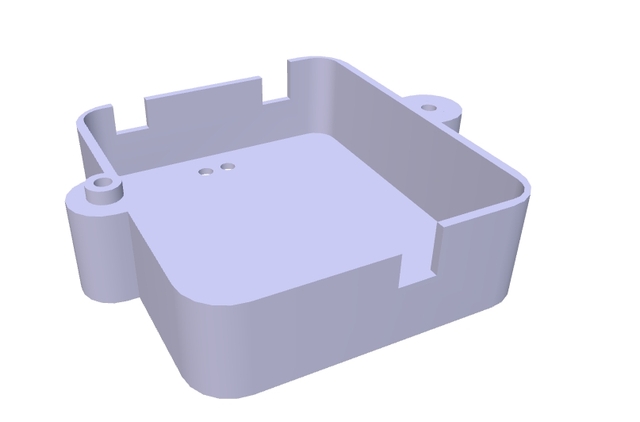

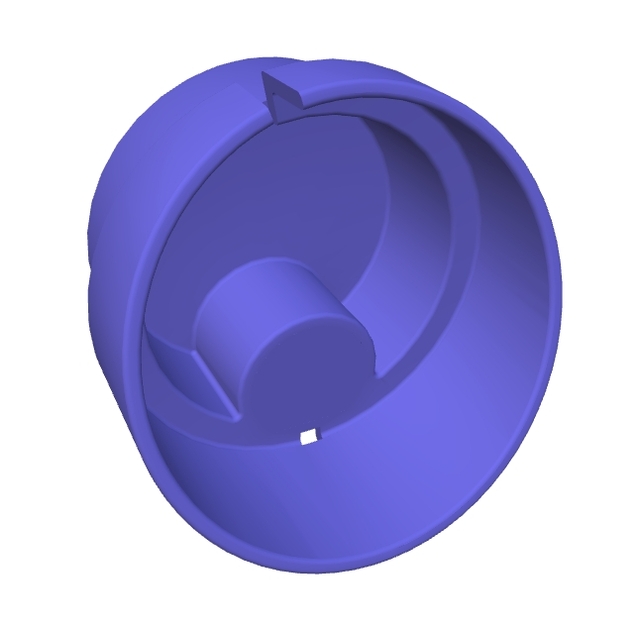

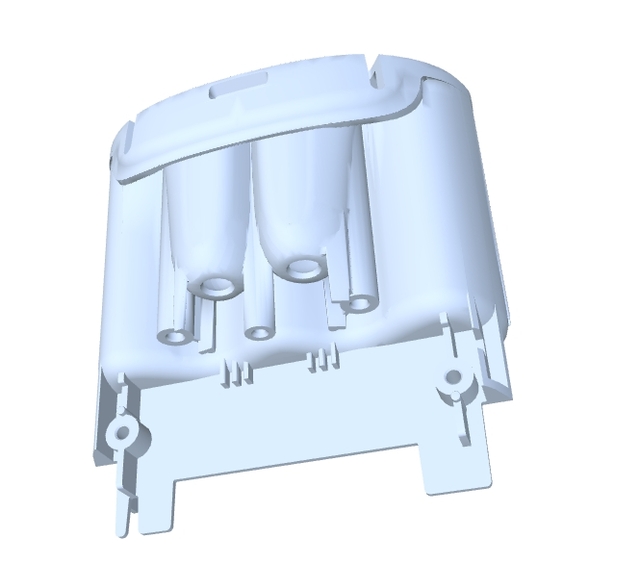

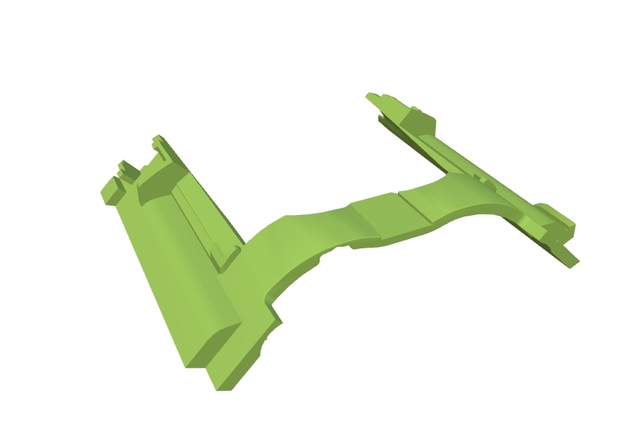

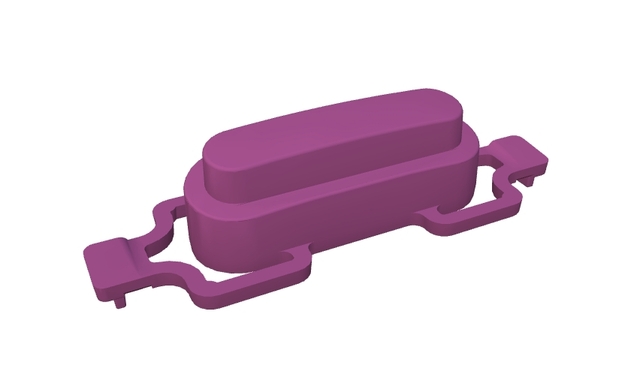

The introduction of the Purple Silicone Strap Clip exemplifies the innovation and diversification plastic molding has brought to product development. This stylish, vibrant accessory is crafted using durable, flexible silicone, combining strength with comfort. Its eye-catching design not only adds a touch of bold elegance but also reaffirms the broad capabilities of plastic molding. Injection molded components like these are increasingly being used in various applications, from organizing equipment to accessorizing tech gadgets, showcasing the versatility of plastic mold design.

Beyond aesthetics, the functionality of the Purple Silicone Strap Clip is achieved through meticulous product development techniques, such as CNC machining and prototype injection molding, facilitating precise adjustment of the clasp design. The mold used in injection molding is typically designed to accommodate multiple cavities, enabling mass production of the clip while ensuring each piece retains its integrity and dimension. This multi-cavity approach streamlines manufacturing, ensuring the clip can be produced in large quantities without sacrificing quality, a testament to the power of thermoplastic injection molding.

Industrial plastic injection molding techniques ensure that even complex parts, like the clasp of this strap clip, can be manufactured with excellent detail, demonstrating the possibilities of injection molding machines. These machines are pivotal in the modern production landscape, shaping nearly every plastic item we use today. By leveraging these technologies, manufacturers not only achieve desirable outcomes but also contribute to reducing environmental impact through efficient use of materials and energy. The inclusion of advanced processes like thermoplastic and CNC machining of plastic parts illustrates how modern industrial practices blend effectiveness with sustainability.

In essence, the Purple Silicone Strap Clip represents more than just a functional accessory; it is a notable embodiment of innovation within the plastic manufacturing world. As the demand for high-quality, custom plastic parts continues to grow, so too does the need for advanced plastic manufacturing processes and practices. The future of plastic injection molding is bright, with infinite possibilities for customization and innovation in creating durable and aesthetically appealing products that cater to evolving consumer needs and preferences.

Revolutionizing Production: Plastic Injection Molding Techniques

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

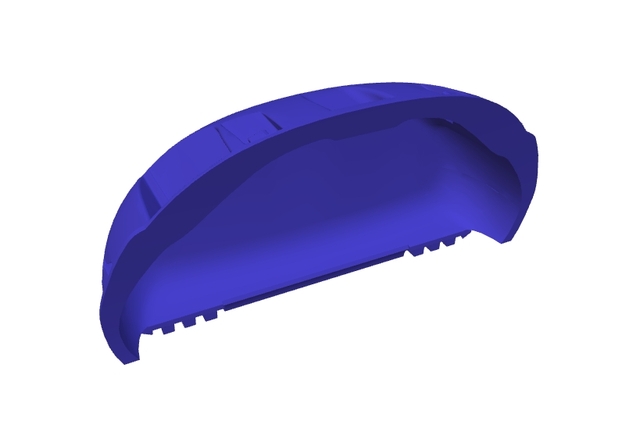

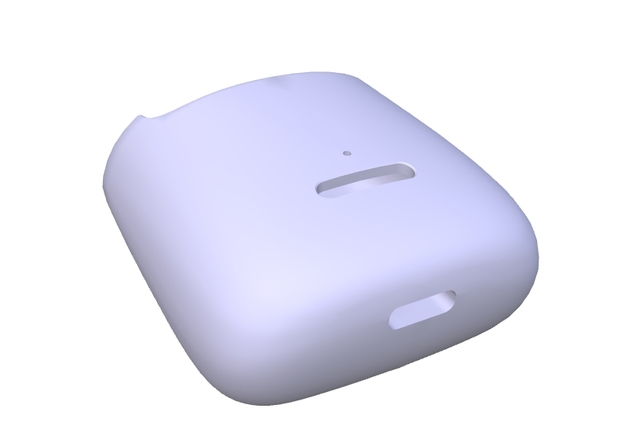

Plastic Injection Molding: Innovation in Electronics Cases

Innovations in Plastic Injection Molding: A Deep Dive into Modern Techniques

Exploring Plastic Injection Molding in Modern Manufacturing

Plastic Injection Molding: Revolutionizing Automotive Components

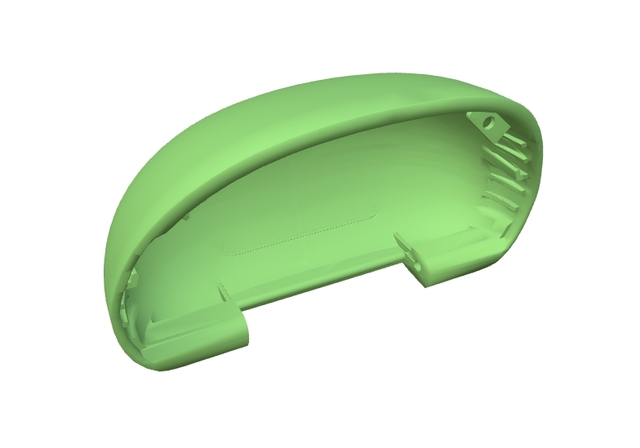

Plastic Injection Molding: The Key to Quality GreenArc Shell

The Future of Plastic Injection Molding: Innovation & Precision

Revolutionizing Production: Plastic Injection Molding Techniques

Understanding Injection Molding Process in Modern Manufacturing