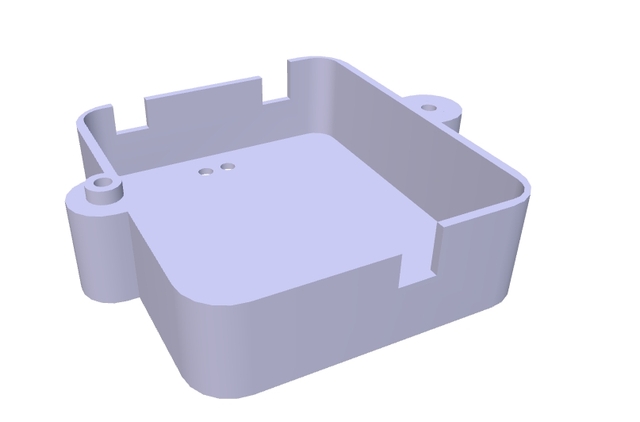

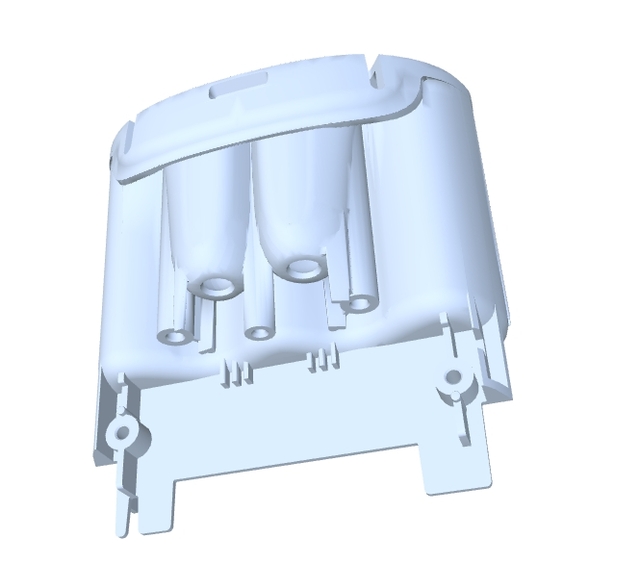

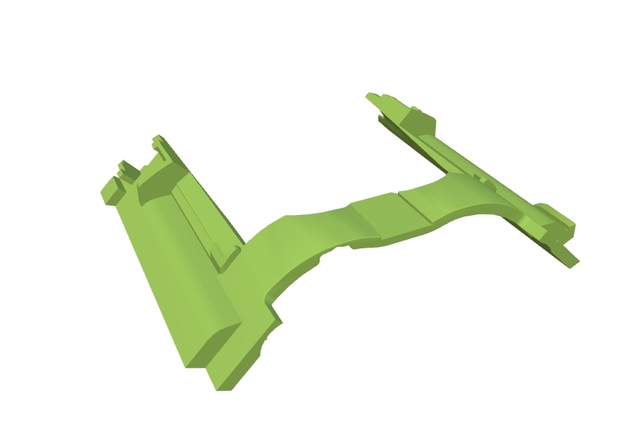

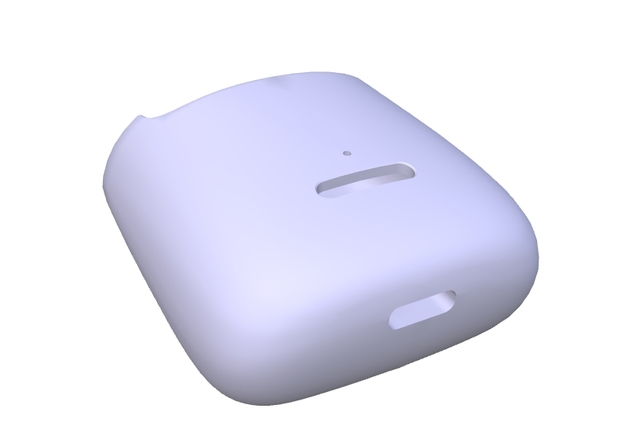

Plastic injection molding is a cornerstone of modern manufacturing, providing high precision and flexibility in creating a wide range of products. This method involves the use of injection molded plastics to craft items with exact specifications and intricate designs. With the increasing demand for custom injection molding services, companies are employing state-of-the-art technology to meet customer needs effectively.

The plastic manufacturing process begins with thermoplastic injection molding. Thermoplastics are chosen for their malleability when heated and solid stability upon cooling. This property allows injection molding companies to produce items with high precision, ensuring each piece's reliability and quality. The process is swift yet meticulous, making it an ideal choice for high-volume productions while maintaining the integrity of the design.

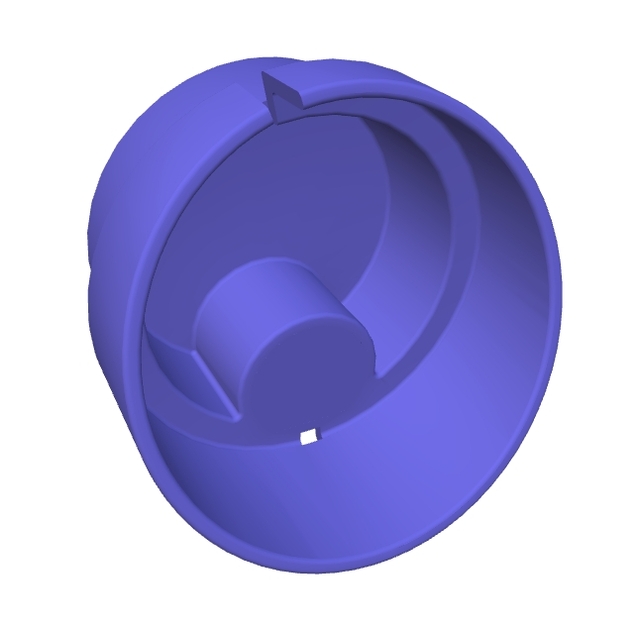

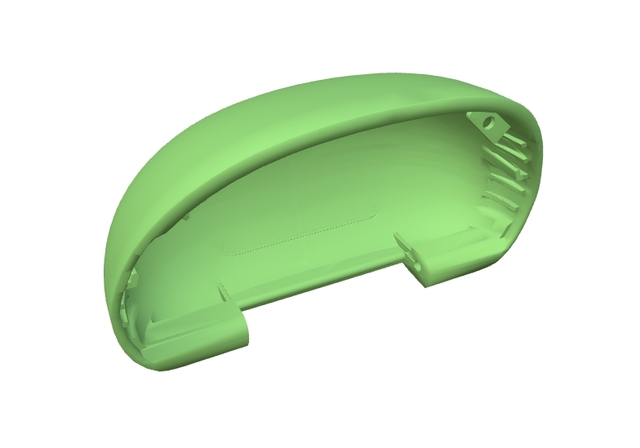

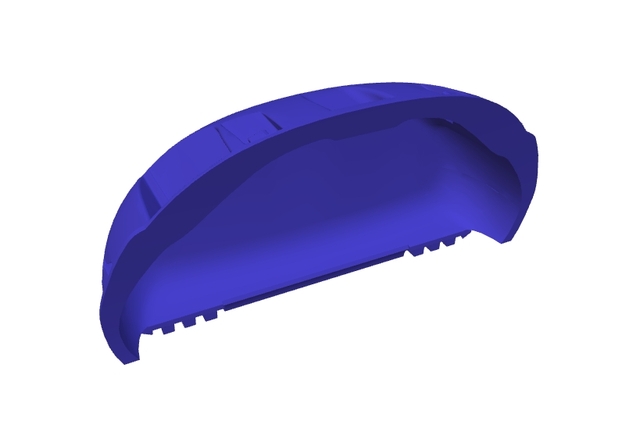

One of the most significant advantages of plastic injection molding is its capacity to cater to both high precision demands and ergonomic design innovations. For instance, consider the newly developed silicone grip accessory. This product exemplifies how injection molding technology enables the creation of ergonomic designs that prioritize both style and function. With its sleek and vibrant blue finish, the silicone grip is not just about aesthetics; its curved contour and ribbed inner surface offer a comfort level that is unparalleled for high-intensity activities or everyday use. Such a design demonstrates the adaptability of plastic mold makers in incorporating modern aesthetics with functionality.

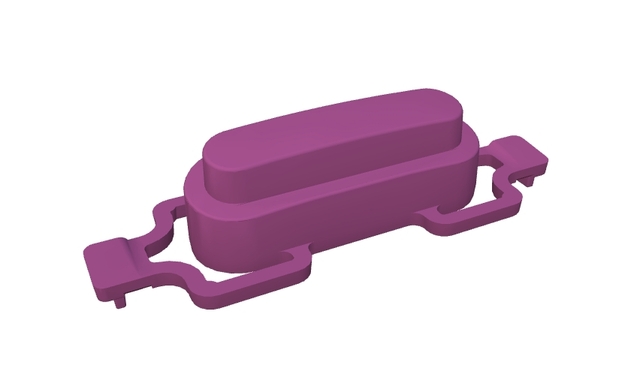

Industry leaders in injection molding are focused on expanding their capabilities to provide bespoke solutions to their clients. Plastic mold makers are increasingly working with designers and engineers to push the boundaries of what's possible with injection molded plastics. By doing so, they are opening new avenues in product design, from simple everyday items to complex components used in various industries. As the technology continues to evolve, we can expect even more innovative products that enhance both user experience and functionality.

In conclusion, plastic injection molding is not just a plastic manufacturing process but a craft that brings together technology, design, and functionality. It's an industry that serves as a backbone for innovative product designs, like the ergonomic silicone grip, by utilizing advanced techniques in thermoplastic injection molding. As injection molding companies continue to perfect this art, consumers can look forward to products that not only meet their needs but exceed their expectations, in both performance and style.

The Future of Plastic Injection Molding: Innovation & Precision

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.