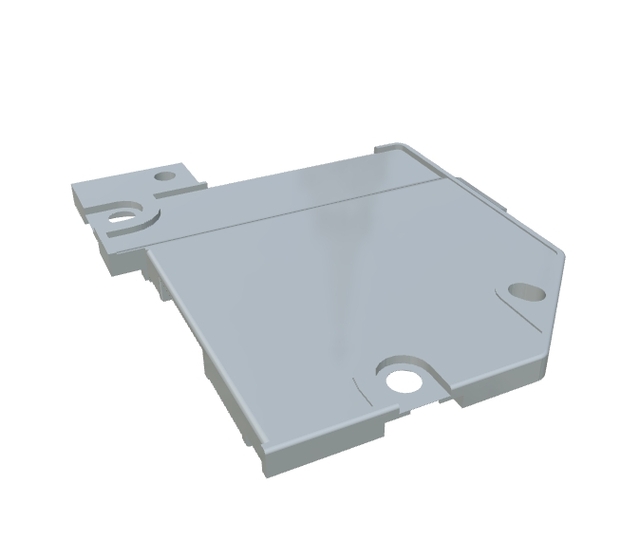

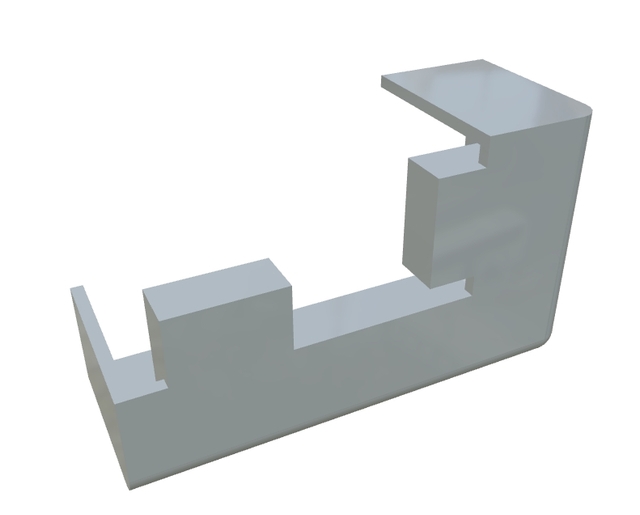

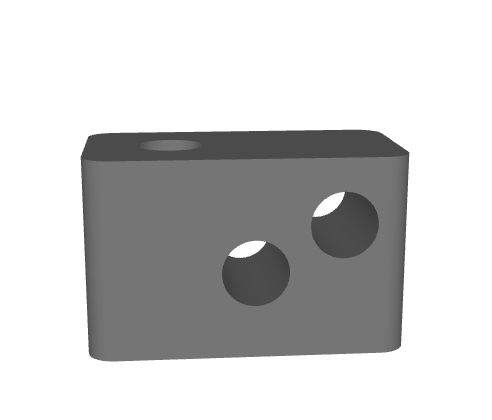

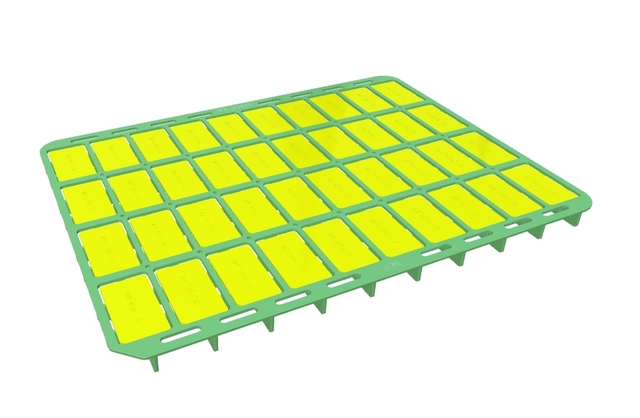

The injection molding process stands as a cornerstone in the manufacturing world, renowned for its efficiency in producing large volumes of high-quality parts. This method is integral to crafting various items, including injection molded parts such as plastic components and custom-designed objects that cater to specific needs. Injection molding services provide vital support to industries seeking precision and consistency, especially in the realm of plastic injection molding.

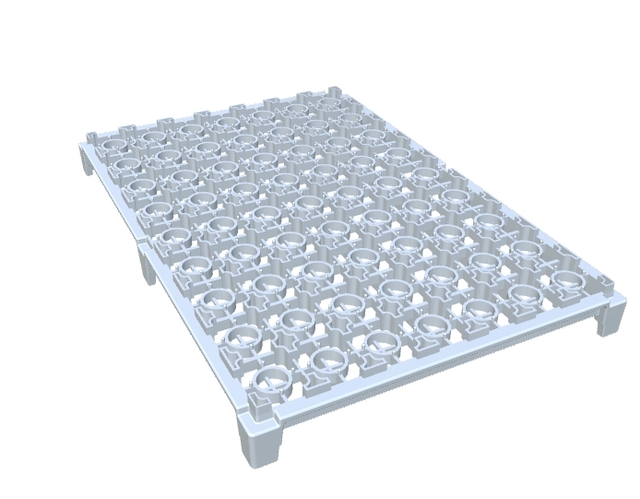

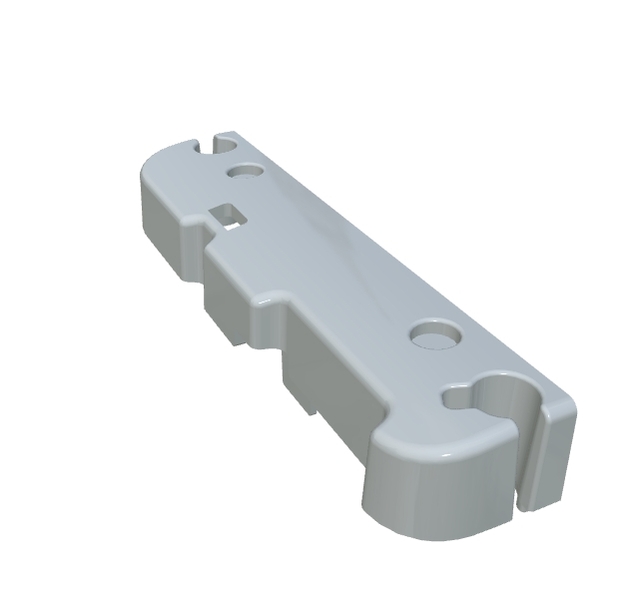

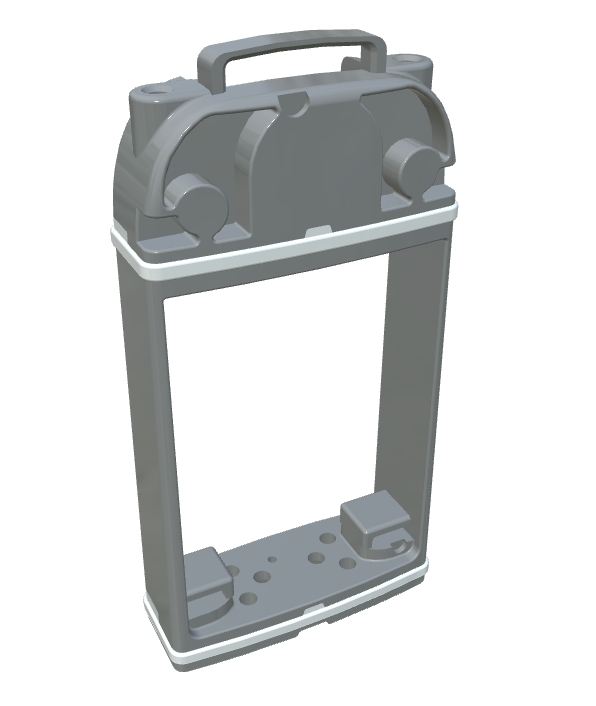

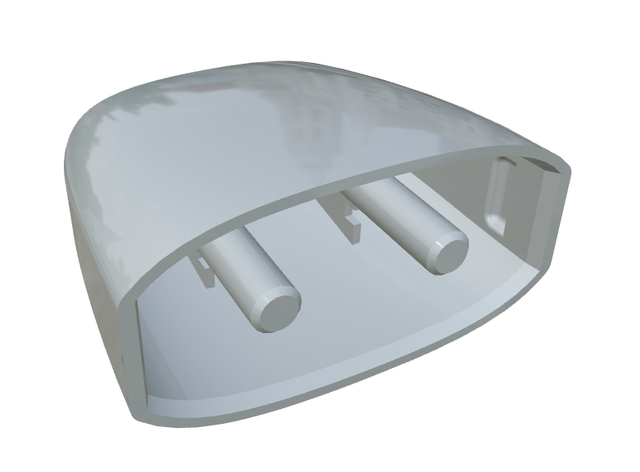

Central to the injection molding process is the injection molding machine, an assembly line powerhouse that injects molten material into a mold cavity. These machines are invaluable to the industry, allowing manufacturers to produce a diverse range of products with intricately detailed features. The machine's capability to handle different materials, primarily plastics but also metals and ceramics, ensures flexibility in the creation of parts designed for specific applications.

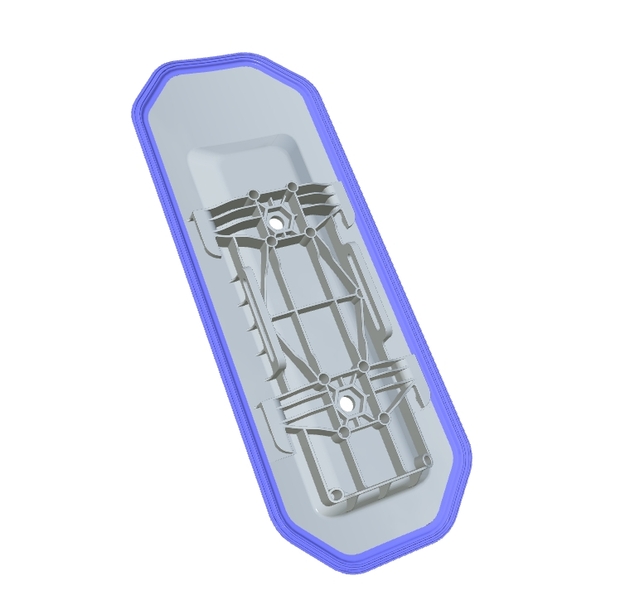

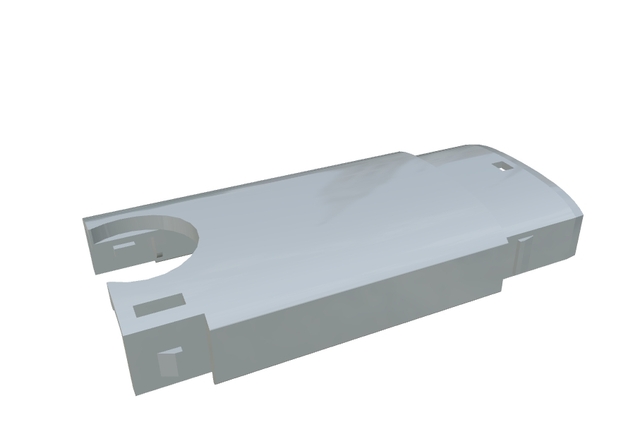

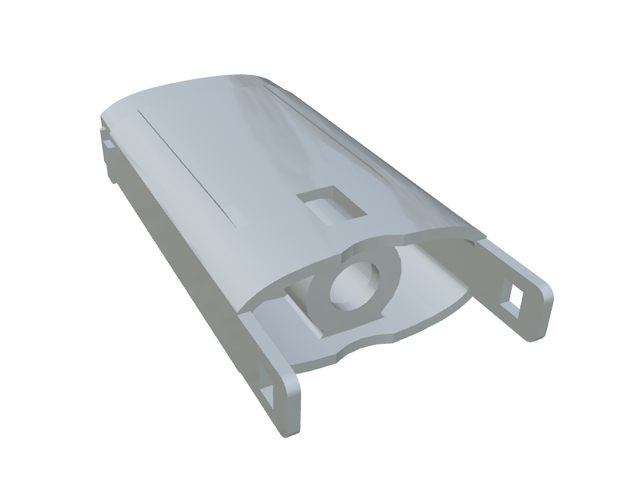

Injection molding manufacturers play a pivotal role in the production chain. These experts specialize in the injection mold design process, a critical phase involving the creation of molds that define the shape and detail of the finished product. A well-designed mold is essential for achieving the desired quality and function of the product, ensuring that each piece meets stringent standards.

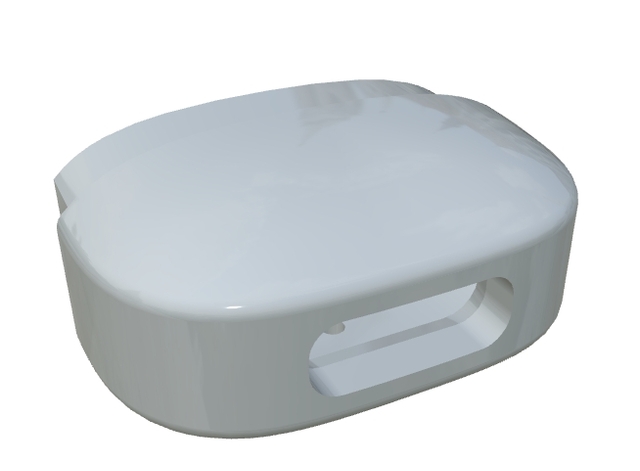

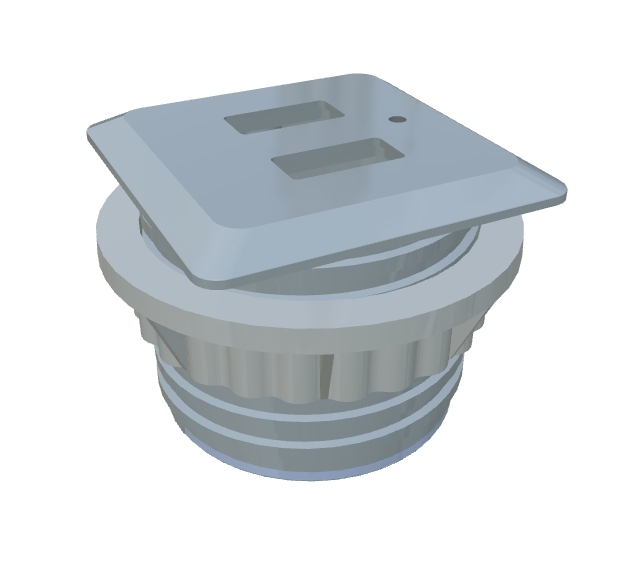

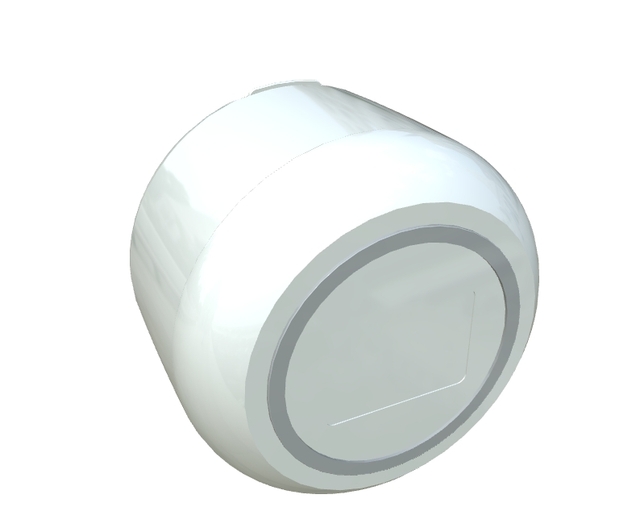

While the injection molding process primarily centers on industrial applications, the principles behind it can also be adapted for creating elegant consumer products. For instance, consider a sleek, elegantly designed ceramic vase made through a similar molding technique. Crafted from high-quality white porcelain, this vase is not only a masterpiece of injection molding precision but also a testament to the process's versatility. With its glossy finish that beautifully reflects light, the vase becomes a sophisticated decor item in any contemporary space, aligning with both classic and modern aesthetics.

Incorporating this manufacturing technology into everyday objects underscores the importance of injection molding services. Whether producing industrial parts or items meant for home decor, the process remains indispensable due to its ability to ensure high-volume production without sacrificing quality. From injection molded parts that power machinery to custom designs crafted to meet unique consumer needs, the capabilities of injection molding are vast, and its impact on modern manufacturing processes is profound.

As we continue to advance technologically, the significance and applications of the injection molding process are only expected to grow. Whether you're a manufacturer looking to optimize production or a consumer seeking high-quality goods, the injection molding industry remains a critical contributor to both innovation and practicality.

Mastering the Injection Molding Process for Quality Parts

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

CNC Machining: Precision Innovations in Automotive Parts

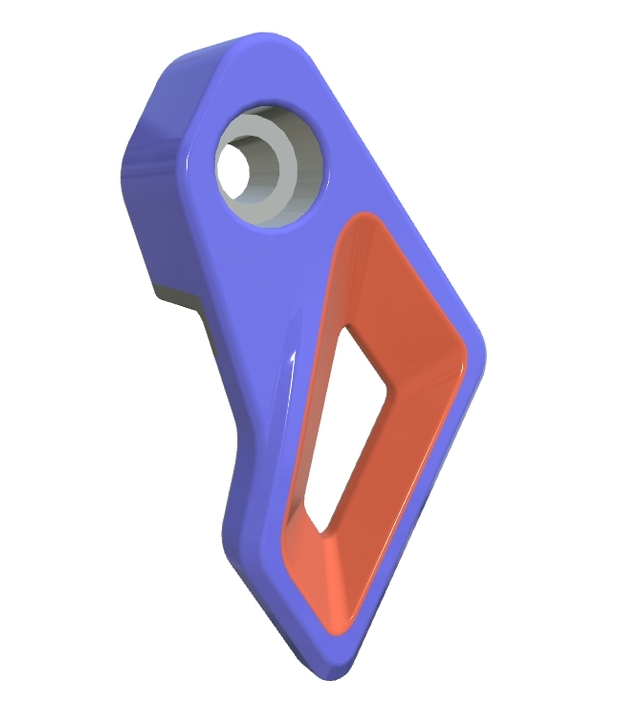

Mastering the Overmolding Process for Superior Design

Overmolding Process: Revolutionizing Material Technology

Overmolding Innovations: Unveiling the HexAlign Bracket

Overmolding Techniques: Revolutionizing Smart Lock Design

Unlocking the Overmolding Process: Techniques & Benefits

Mastering the Overmolding Process for Enhanced Products

Overmolding Process: Techniques, Materials & Applications

Exploring Advanced Overmolding Techniques in Modern Manufacturing

Understanding the Insert Molding Process: Advantages and Applications