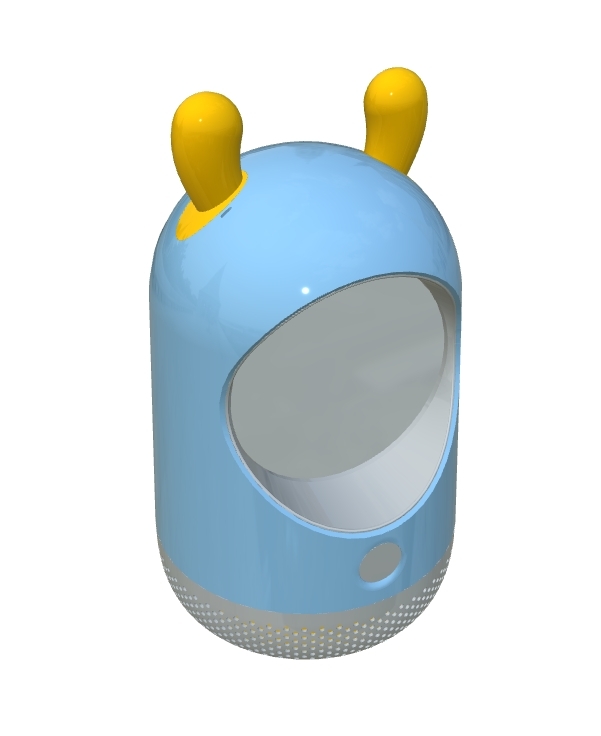

In the world of manufacturing, injection molding is a cornerstone process that has revolutionized the creation of complex parts and products. The injection mold manufacturing industry has seen a significant impact with the advancement of this technology, making it possible to produce intricate designs and high-quality outputs with efficiency. One product that exemplifies the innovative use of the injection molding process is our latest offering—a whimsical and vibrant Bluetooth Speaker Pod.

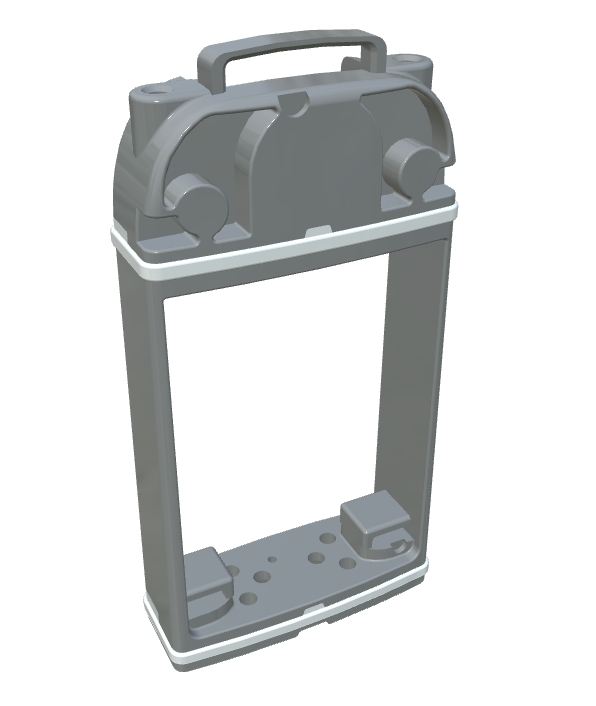

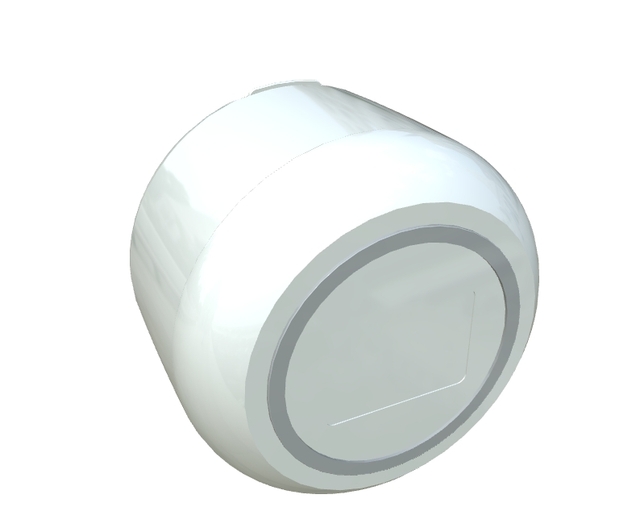

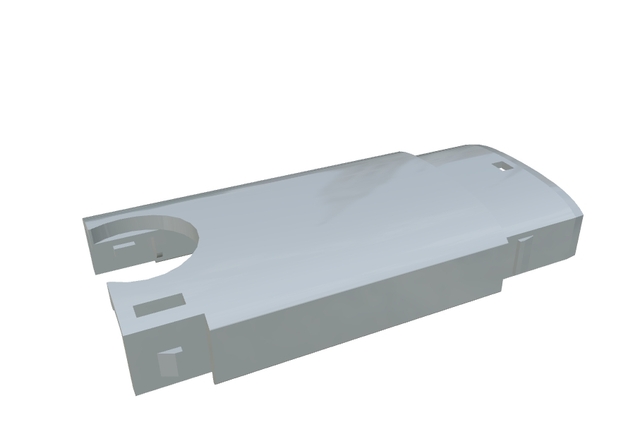

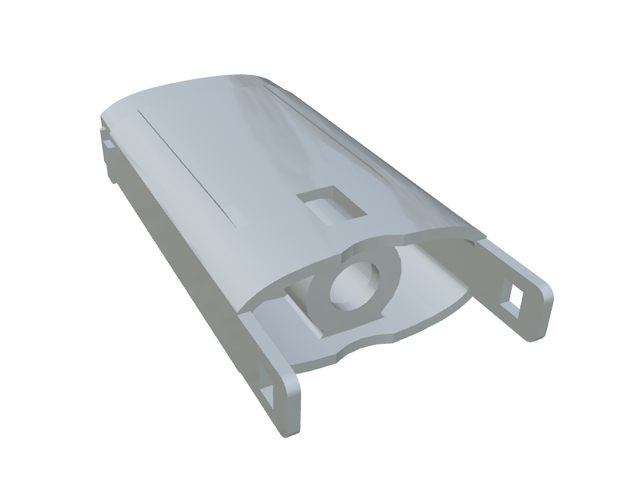

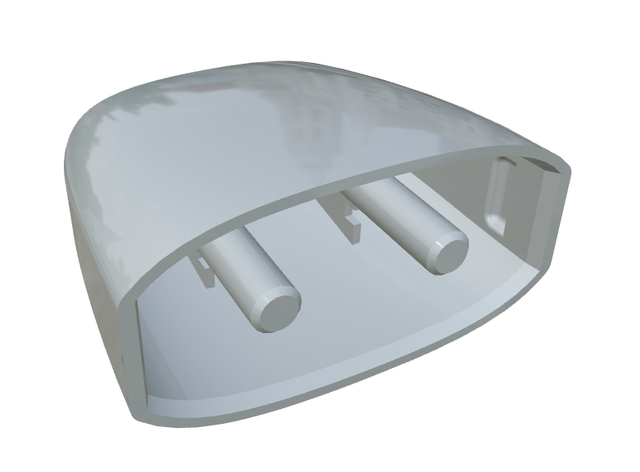

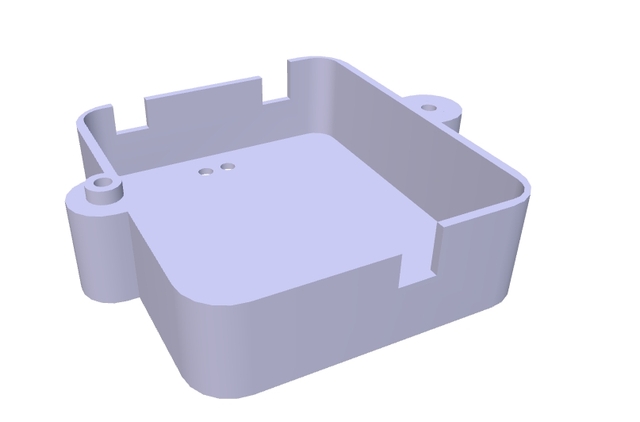

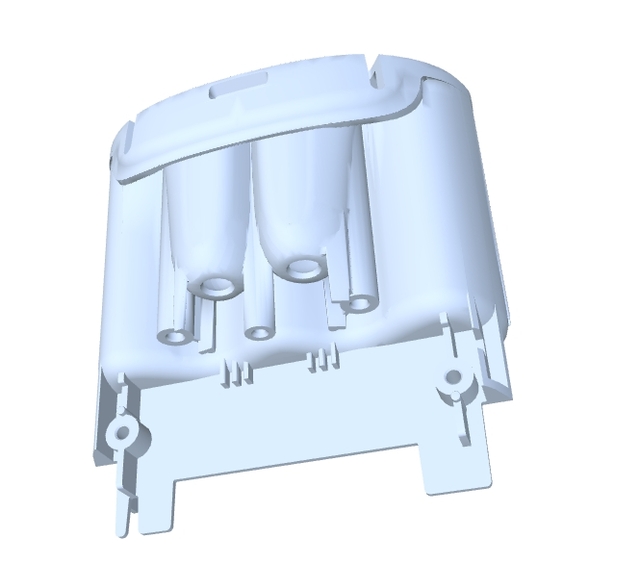

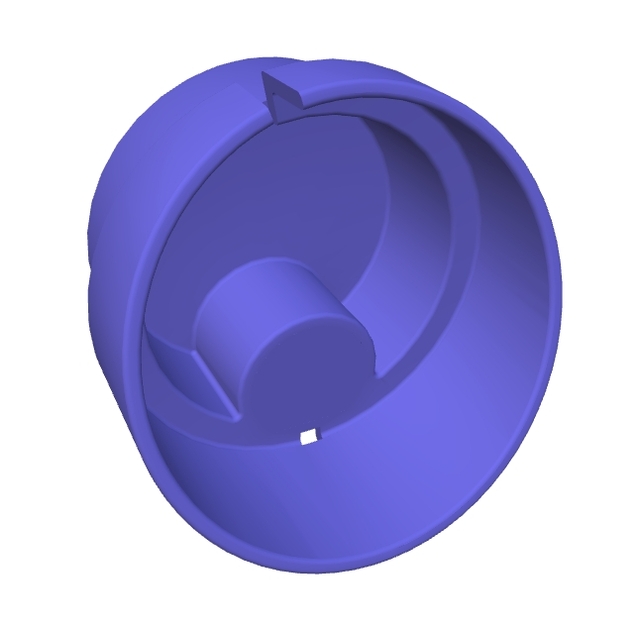

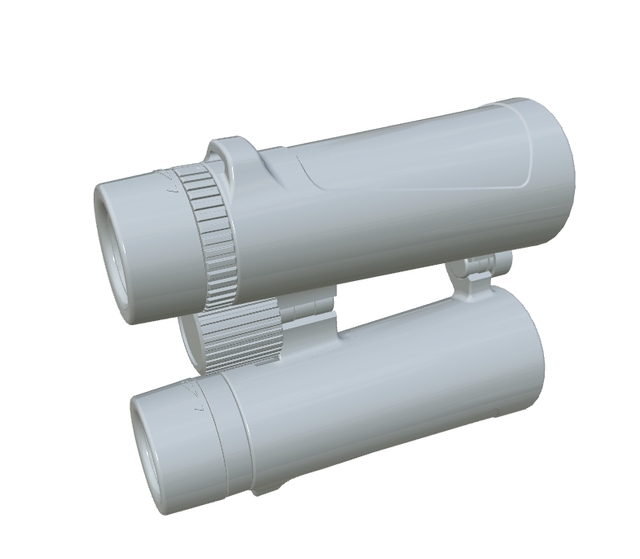

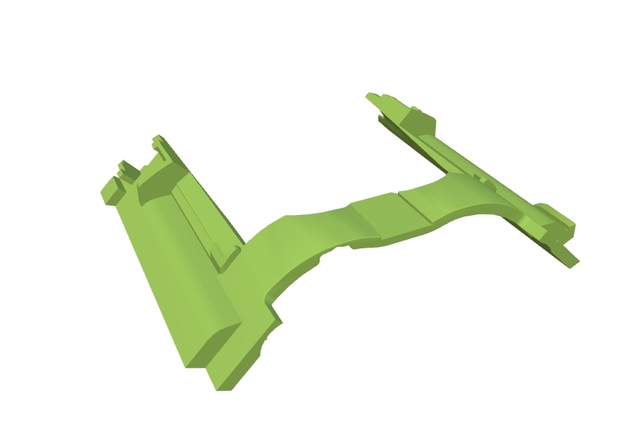

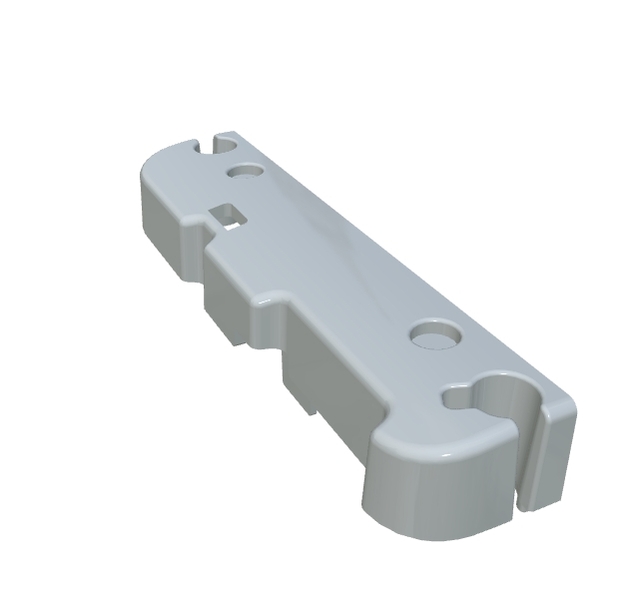

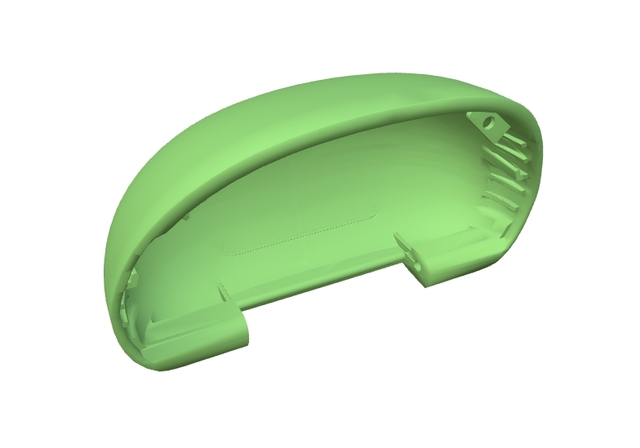

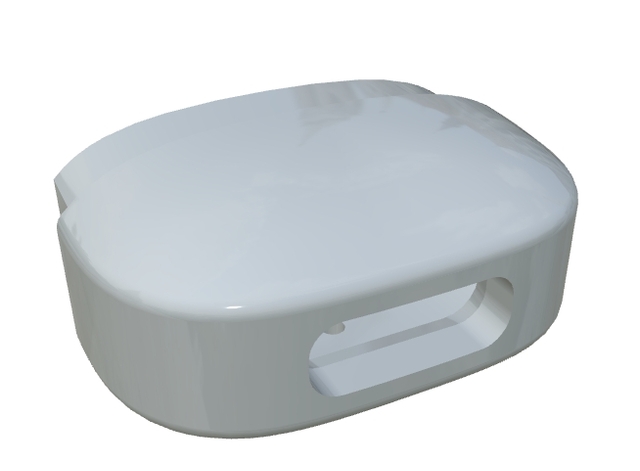

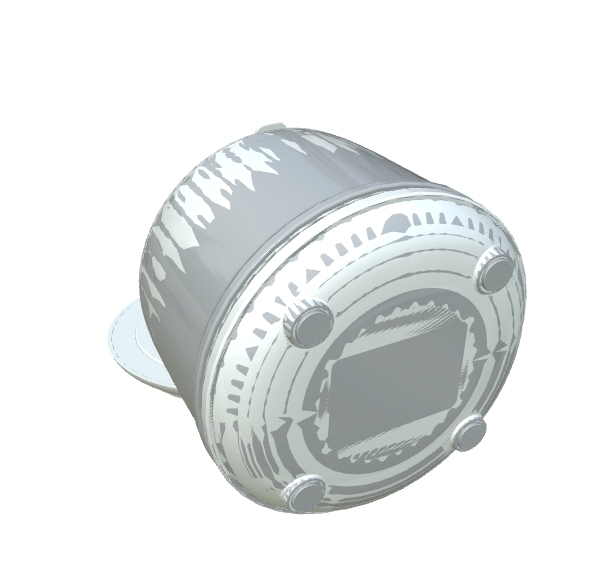

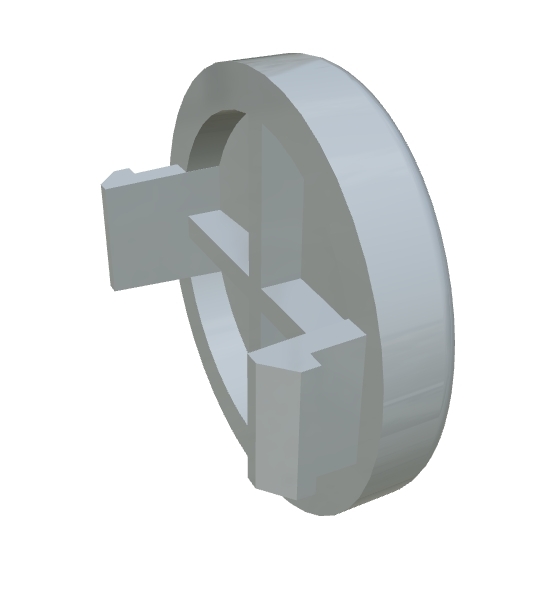

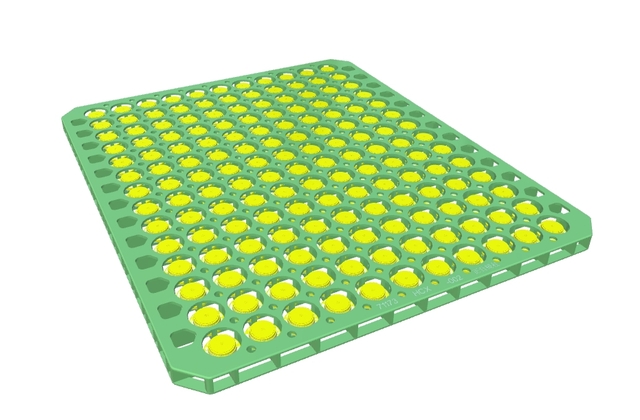

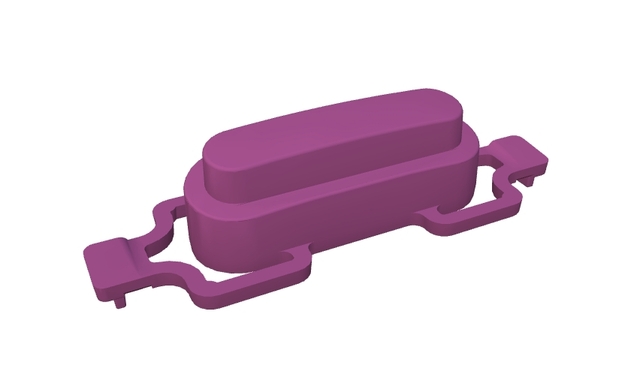

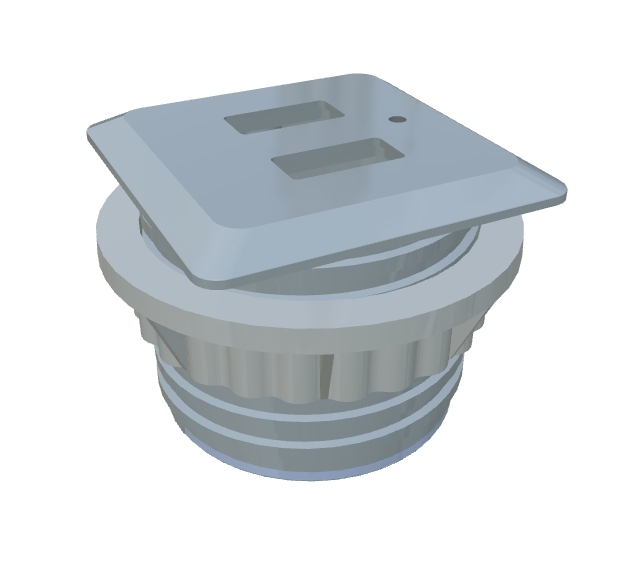

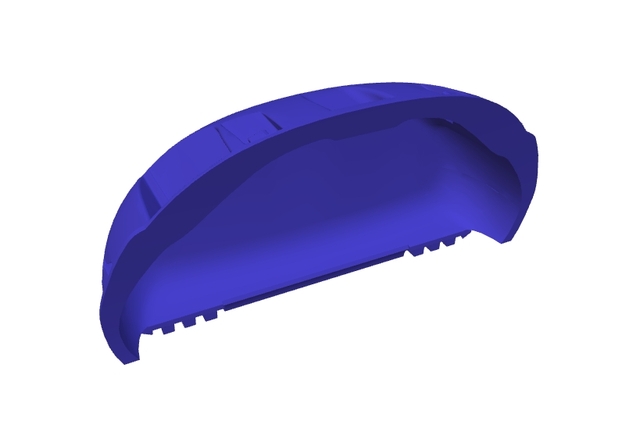

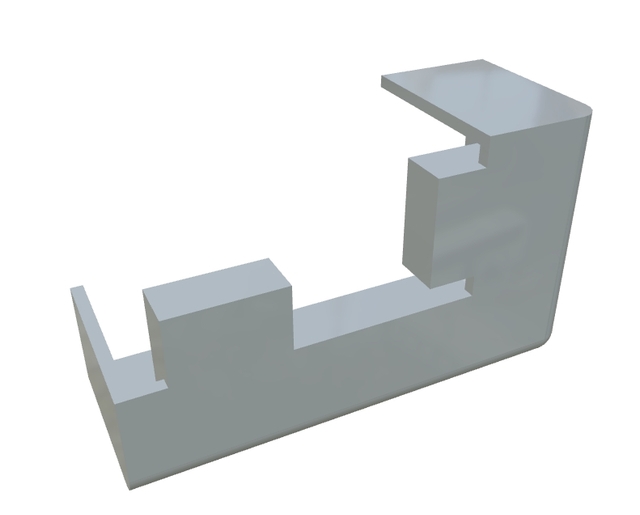

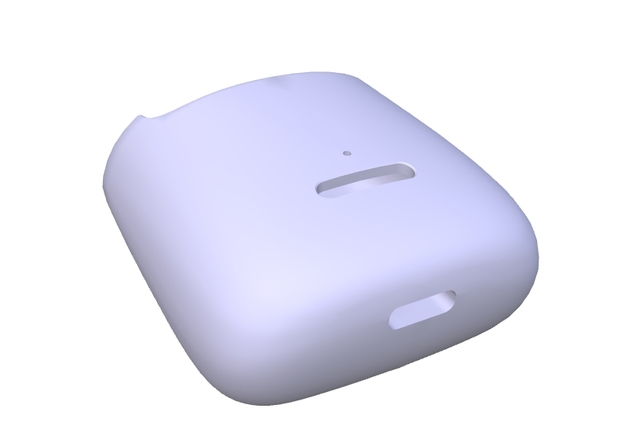

Crafted using plastic injection molding, the Speaker Pod's design showcases the capacity of injection molding to bring intricate, colorful designs to life. The injection molding process allows for the creation of this speaker's sleek, egg-shaped body, combined with a palette of pastel purple and turquoise hues. This artistic expression in color and form not only highlights the aesthetic capabilities of injection molding design but also underscores its functional benefits. The compact and portable nature of the Speaker Pod, enhanced with a convenient loop handle, owes much to the precision and flexibility offered by custom injection molding techniques.

While aesthetic appeal is a significant factor, the Speaker Pod doesn't compromise on functionality. Injection molding services ensure that the speaker remains durable and robust, standing up to the demands of a modern lifestyle. Further enhanced by state-of-the-art Bluetooth technology, the Speaker Pod ensures seamless pairing with various devices, delivering crisp and powerful sound. This is a testament to how injection molding machines and processes can cater to both design and operational demands of modern electronic products.

As the injection molding industry continues to evolve, it brings forth products that balance form and function, like our Bluetooth Speaker Pod. It stands as a celebration of what injection molding can achieve—creating products that are as beautiful as they are useful. Whether you're out exploring nature or relaxing at home, this inventive product represents the art of sound innovation through the precision and creativity of injection molding.

Injection Molding in Modern Audio Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

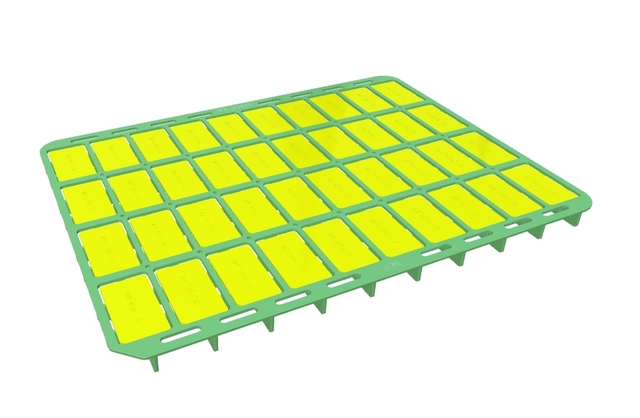

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.