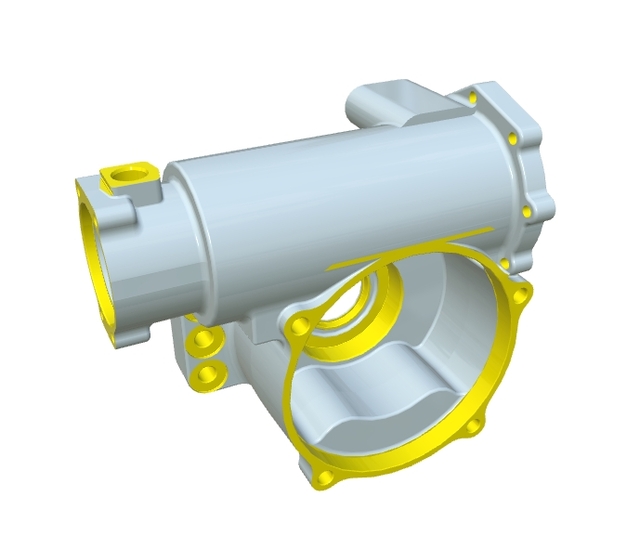

Metal casting techniques are essential processes in manufacturing industries, providing diverse methods and materials to create various metal products. These techniques allow the production of intricate and durable components, appealing to sectors demanding precision and reliability. From the production of aluminum casting components for lightweight products to robust steel casting for heavy-duty applications, the versatility is truly impressive. Incorporating metal casting materials can indeed pave the way for creating high-quality items used across different industries.

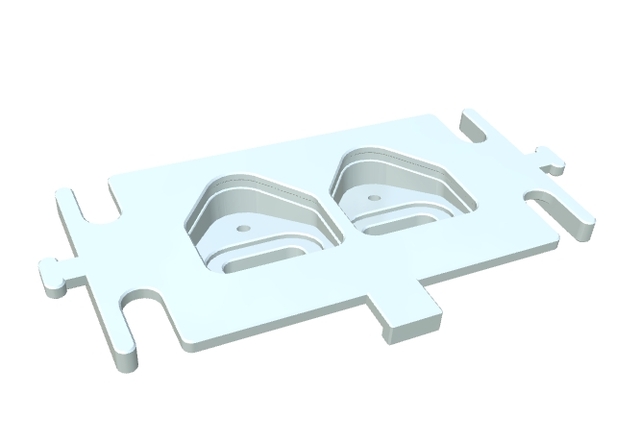

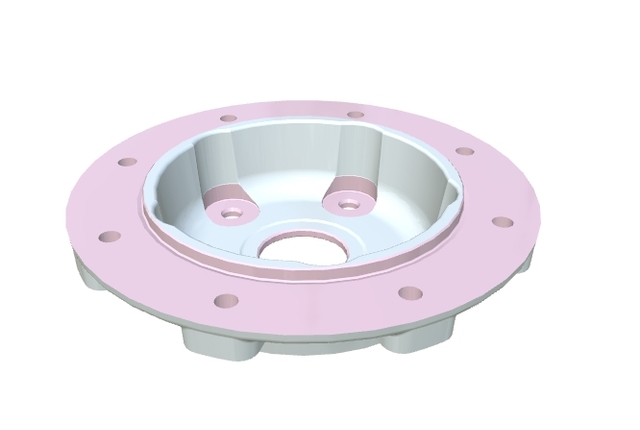

Among these proven methods, investment casting, die casting, and sand casting are prominent techniques, each offering unique advantages tailored to specific needs. Investment casting is ideal for creating complex shapes with precise accuracy, while die casting provides high-volume production efficiency. On the other hand, sand casting offers flexibility in producing oversized components and is widely preferred for its simplicity and cost-effectiveness. These processes collectively contribute to an efficient and productive metal casting process, showcasing the versatility and adaptability required for modern manufacturing.

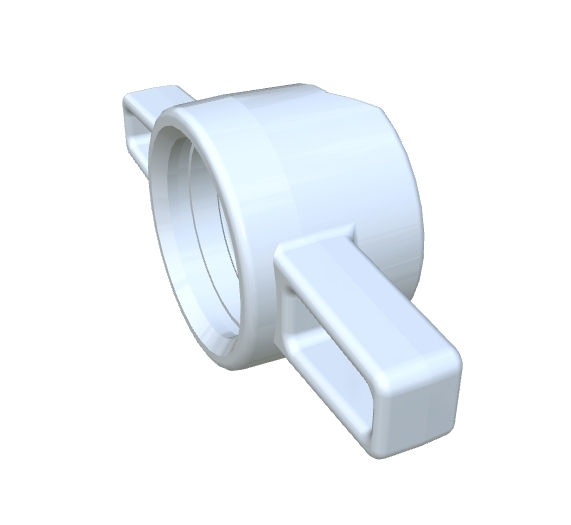

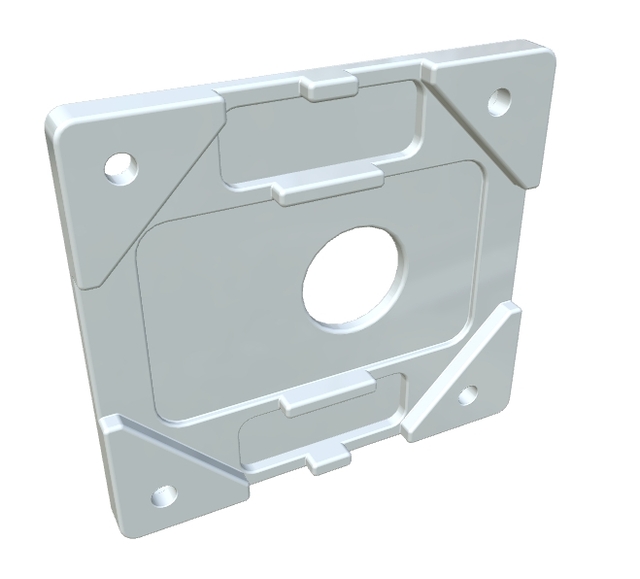

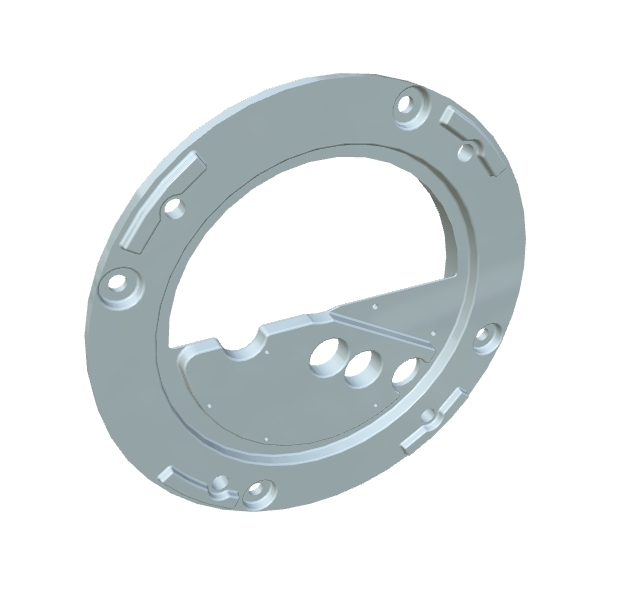

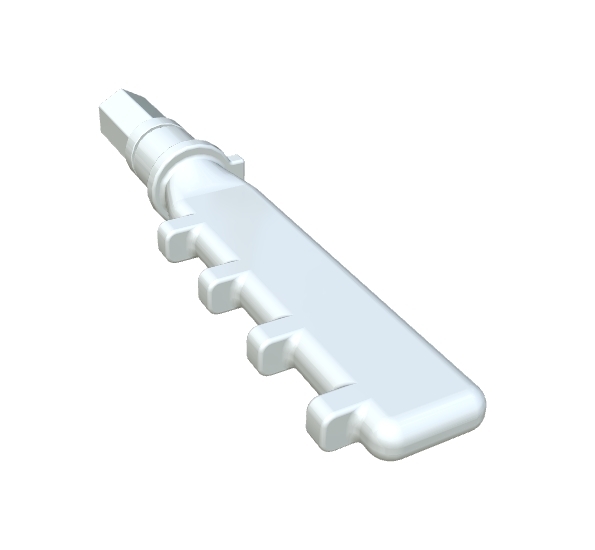

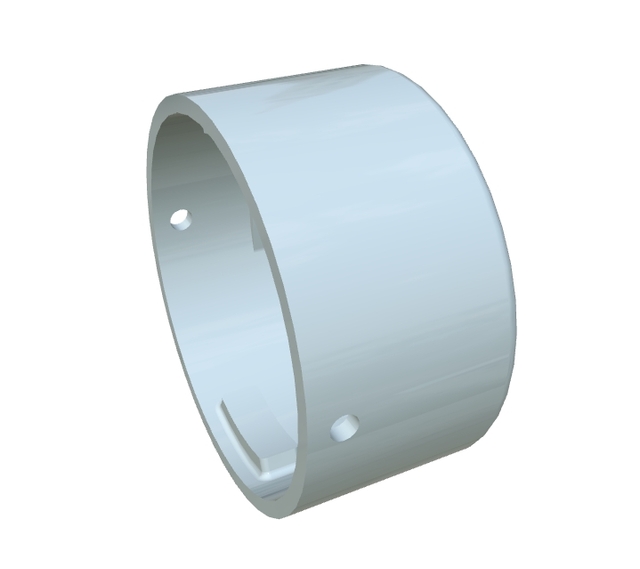

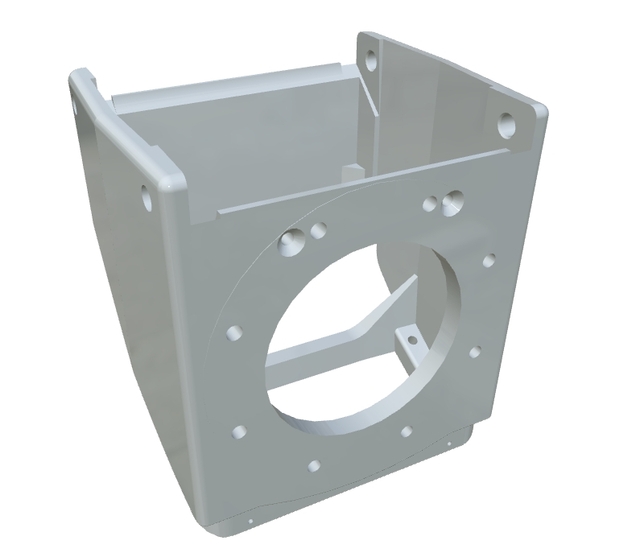

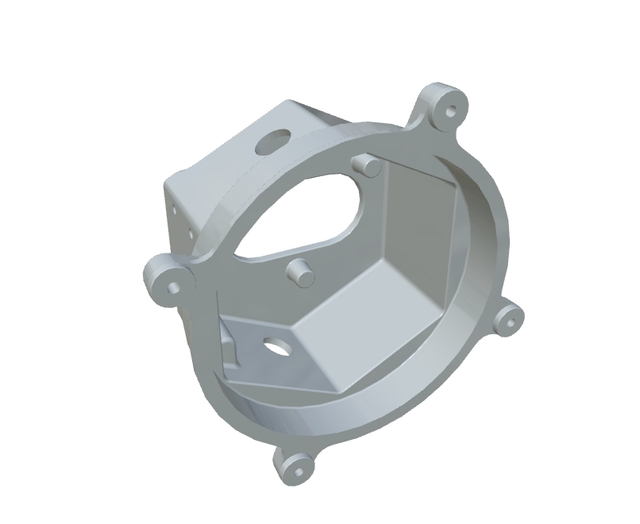

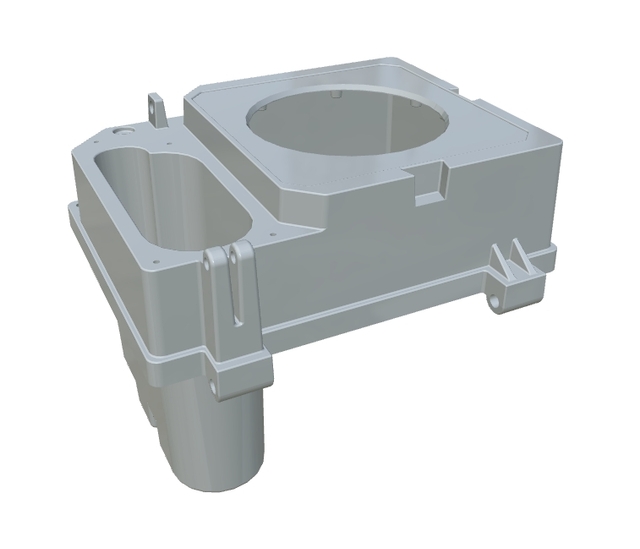

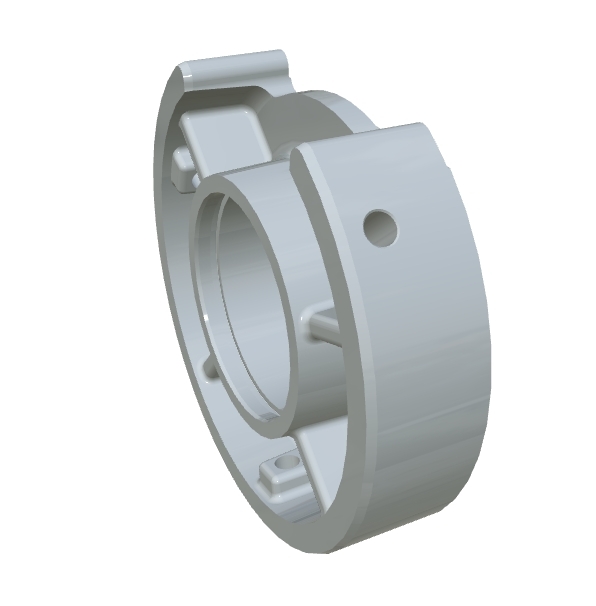

One perfect example where these techniques find application is in the production of CNC accessories. Specifically, the CNC Handwheel, an indispensable tool for precision machining operations, ideally benefits from advanced casting processes. Meticulously crafted from high-quality materials, this sturdy accessory exceeds expectations in wear resistance and reliability. Its ergonomic design ensures exceptional comfort and decreases fatigue, even in prolonged operations. Offering enhanced control and accuracy, the CNC Handwheel transforms the machining experience, cementing its status as an essential tool for professionals and hobbyists alike.

The integration of robust metal casting techniques in producing such high-precision tools highlights the crucial role they play in today's manufacturing arena. As innovations continue to evolve, mastering metal casting processes ensures products like the CNC Handwheel maintain their superior performance, meeting the dynamic needs of industry and customers. Such dedication to quality and precision reflects the commitment to advancing machining capabilities, empowering users with groundbreaking tools that enhance both functionality and design across various applications. The journey towards achieving exceptional results truly starts with choosing the right casting technique – a decision that defines success and satisfaction.

Exploring Metal Casting Techniques for CNC Precision

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting, Metal Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.