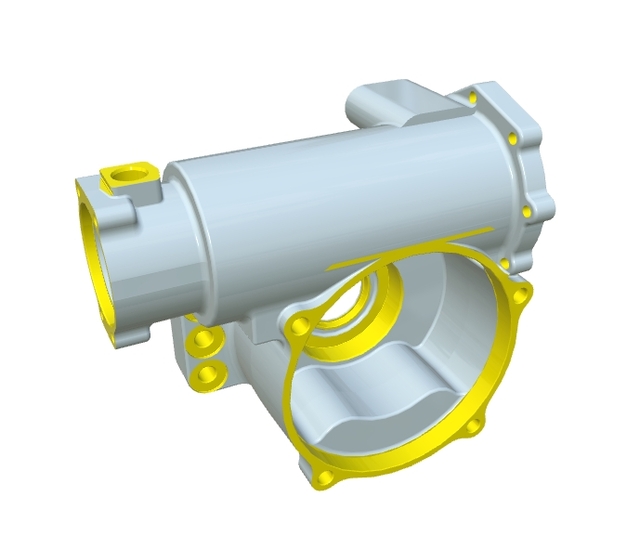

The low pressure casting process is revolutionizing the way industries approach component manufacturing, thanks to its precise control over casting parameters and improved material properties. Central to this innovative technique is its application in producing robust and versatile components such as the Mounting Bracket Plate. Crafted with efficiency and functionality in mind, this product takes advantage of low pressure aluminum casting, ensuring durability and reliability in diverse environments.

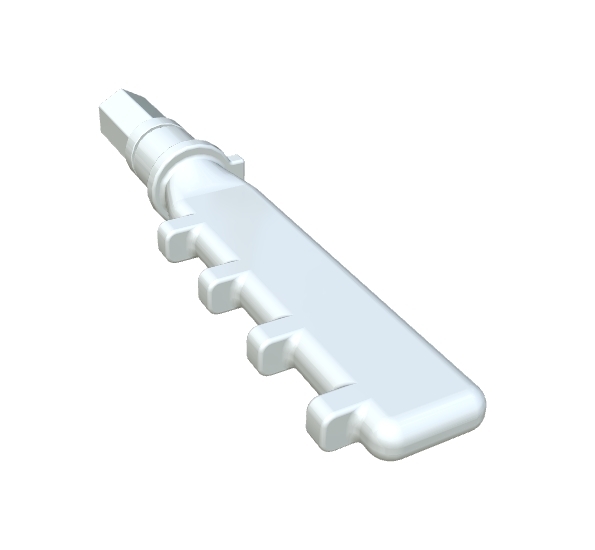

The advantages of low pressure casting are numerous, making it ideal for producing high-quality components like the Mounting Bracket Plate. Unlike traditional methods such as sand casting, low pressure casting allows for a smoother surface finish, enhanced mechanical properties, and reduced casting defects. This process also enhances quality control, minimizing impurities and ensuring consistent performance standards. Engineers appreciate the customization possibilities low pressure casting offers, including complex shapes and designs that other methods may struggle to achieve.

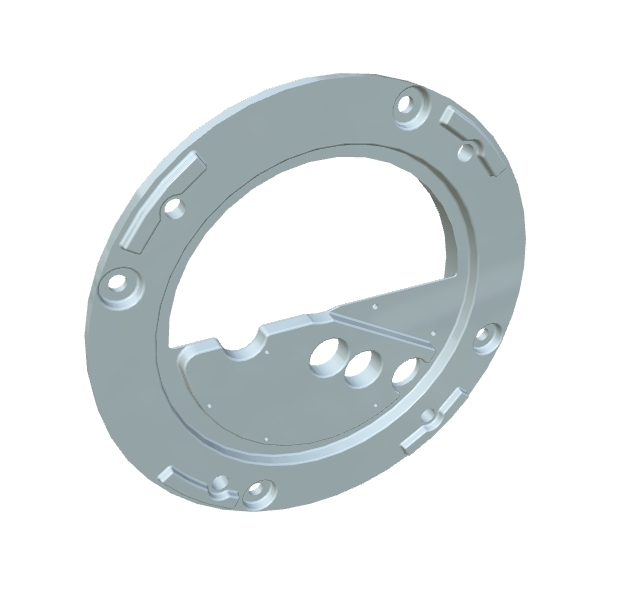

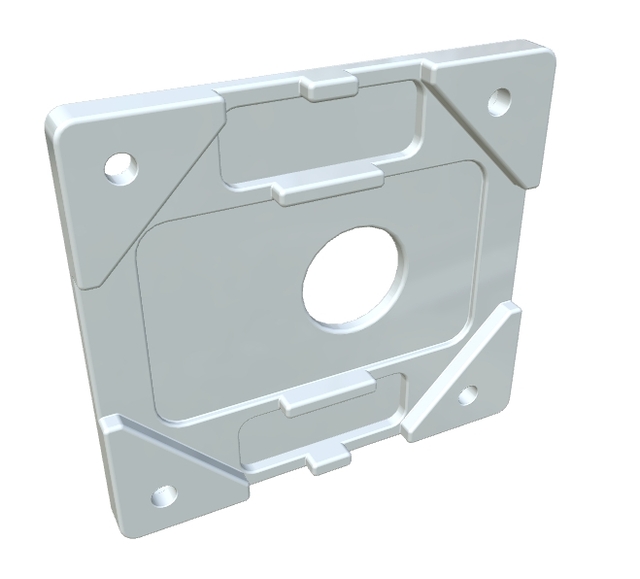

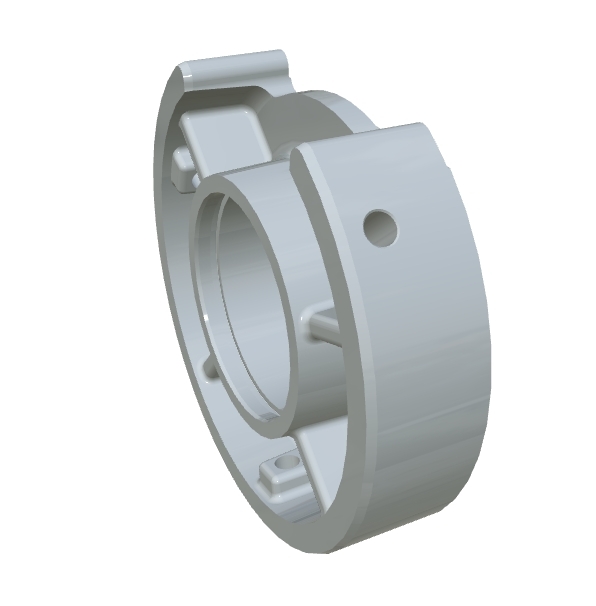

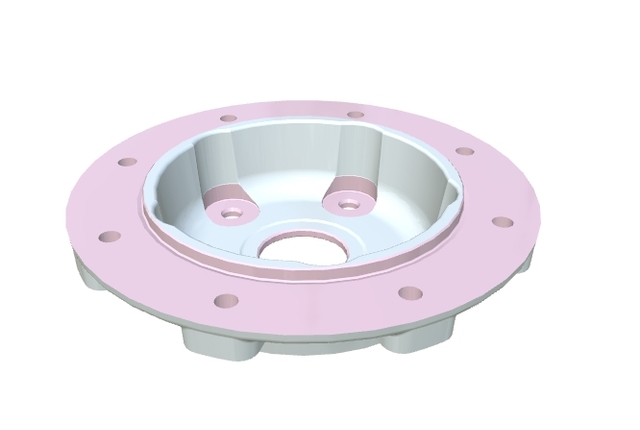

Low pressure die casting is particularly beneficial for applications requiring structural integrity and precision, as demonstrated by the Mounting Bracket Plate's design. Featuring strategically placed reinforcement ribs and a central circular aperture, the bracket is engineered for superior support and versatile compatibility. The use of low pressure casting materials not only bolsters the component's strength but also enhances its aesthetic appeal, making it suitable for both industrial and stylish home installations.

As low pressure casting becomes more prevalent, its industry standards continue to evolve, embracing technological advancements that drive innovation. The process flow of low pressure aluminum die casting facilitates the creation of products that meet stringent quality benchmarks while allowing for efficient production. Manufacturers increasingly invest in low pressure casting machines to optimize their output and maintain competitive edges in their respective fields.

Whether considering low pressure casting applications for industrial connectors or the detailed design of custom low pressure casting services, this technology undeniably offers significant potential. The Mounting Bracket Plate exemplifies the seamless blend of functionality, stability, and modern design achievable through this sophisticated process. As industries continue to explore the depths of low pressure casting, the future looks promising for both established practices and emerging pioneers in component manufacturing.

Mastering the Low Pressure Casting Process for Durability

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.