In the rapidly evolving world of engineering and manufacturing, precision and reliability are paramount. Among the innovative techniques making strides in this field is **low pressure casting**, a method valued for producing high-quality components with excellent mechanical properties. This method is particularly beneficial for crafting intricate parts, such as our latest engineering marvel, the Precision Flange Hub.

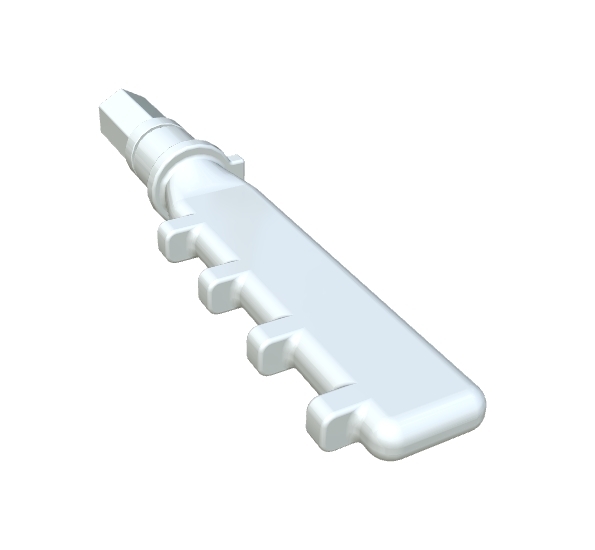

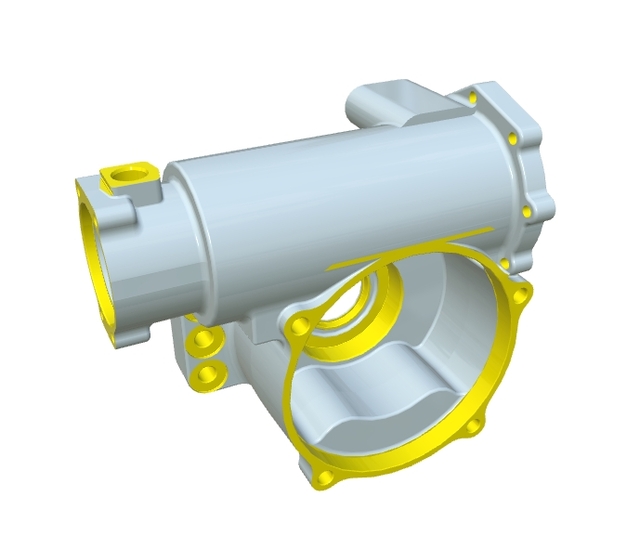

**Low pressure casting process** involves the use of a controlled amount of pressure to gently push molten metal into the mold cavity. This technique helps in producing parts with superior surface finishes and reduced casting defects, making it a favored choice over traditional casting methods like sand casting. The **advantages of low pressure casting** include improved strength, enhanced durability, and precise dimensional accuracy, which are vital for components used in high-stress environments, such as those found in automotive or aerospace industries.

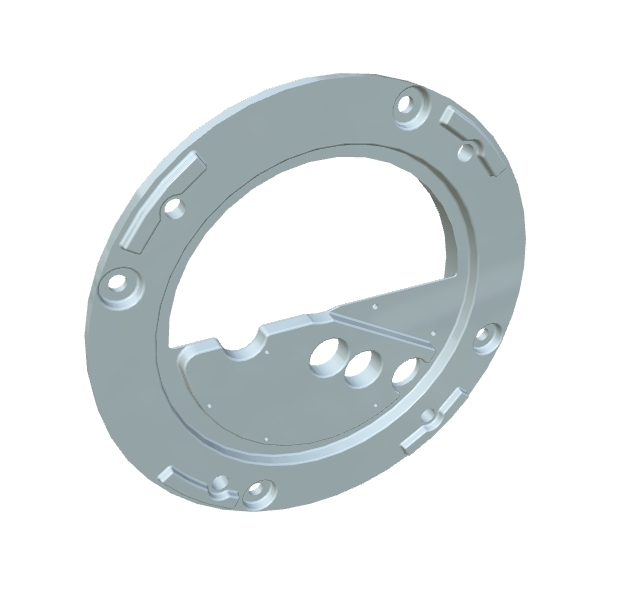

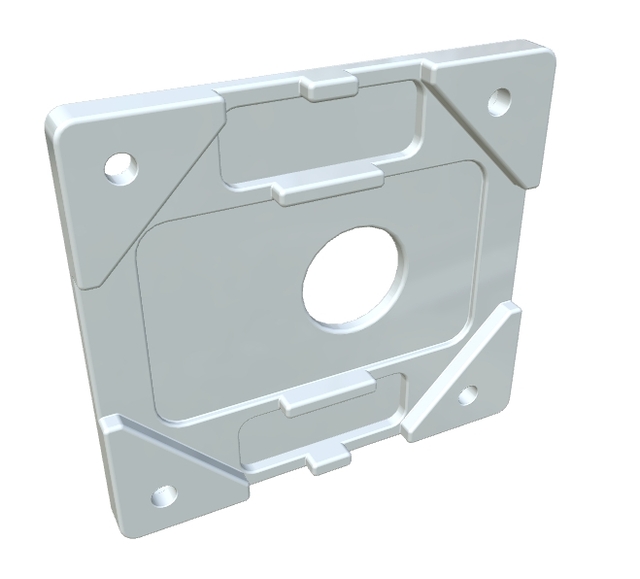

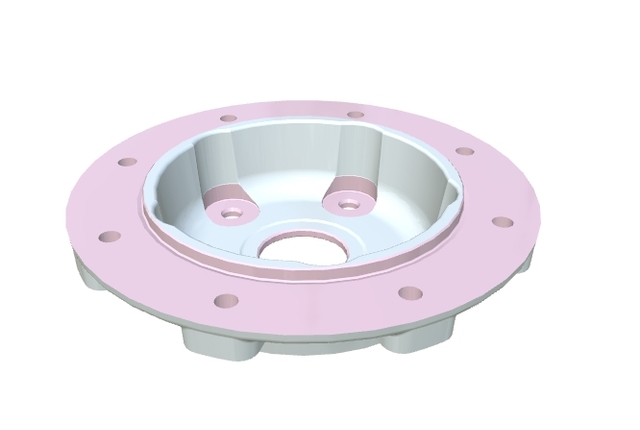

Our Precision Flange Hub is a prime example of what can be achieved through **low pressure aluminum casting**. Crafted from high-grade materials, this component not only exhibits exceptional robustness and reliability but also a sophisticated dual-tone aesthetic. The pink and white finish adds a touch of style to industrial applications, making it suitable for custom engineering projects where both performance and design are crucial.

In addition to its aesthetic appeal, the Flange Hub features multiple evenly-spaced bolt holes for secure attachment and stability, a central cavity engineered for versatile compatibility, and seamless integration with a variety of machinery. This makes the hub a perfect fit for diverse applications, showcasing the flexibility and capability of **low pressure foundry** techniques.

While the method comes with its own set of challenges, such as potential **low pressure casting defects** like porosity if not managed properly, the benefits far outweigh the drawbacks. Custom low pressure casting, in particular, allows for tailored solutions that meet specific design and functional requirements, elevating the manufacturing process to new heights of excellence.

Ultimately, the choice between **high pressure vs low pressure casting** depends on the specific needs of a project. However, the intricate detail, consistency, and high-quality finishes offered by low pressure methods make it an attractive option for industries seeking to push the boundaries of innovation and quality. The Precision Flange Hub stands as a testament to this capability, embodying our commitment to precision and excellence in every component we produce.

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.